Wire rod production technology for ocean hose capable of resisting high pressure and high-concentration acid corrosion

A production process and high-concentration technology, applied in the field of marine hose wire rod production process, can solve problems such as corrosion, economic loss, hose failure, etc., and achieve the effect of high corrosion resistance and high strength corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Specification: φ14mm1 furnace, 101.2t in total

[0024] (1) Smelting composition: C=0.14%, Si=0.39%, Mn=0.62%, P=0.011%, S=0.0019%; Alt=0.030%; refining slag basicity 6.3, white slag refining 33min, soft blowing 12min , the tundish temperature is 1544°C (the superheat of molten steel in the tundish is 23°C), the casting speed is 2.2m / min; the electromagnetic stirring current of the mold is 350A, the frequency is 4Hz, the electromagnetic stirring current at the end is 500A, and the frequency is 12Hz; The cross-sectional size of the billet is 150mm×150mm.

[0025] (2) Heating temperature: 1110-1135°C, starting rolling temperature: 970-1000°C; finishing rolling temperature: 940-970°C; rolling speed 85m / s; spinning temperature: 868-880°C; roller table speed 0.15m / s s; The damper of the fan is fully closed, and the insulation cover is fully closed except for 1#.

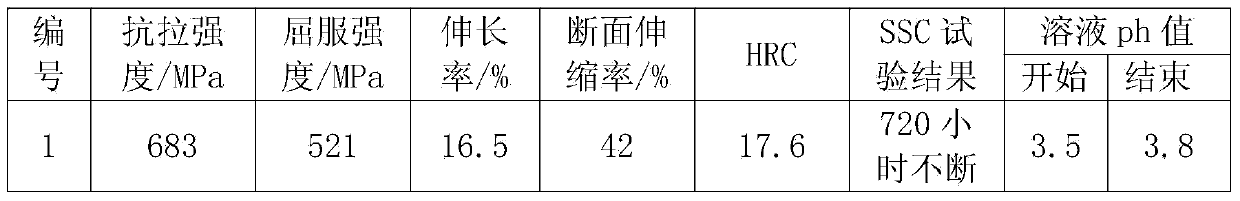

[0026] The results of the SSC test are as follows:

[0027]

[0028]

[0029] Note: The stre...

Embodiment 2

[0036] Embodiment 2: Specification: φ10mm1 furnace, 103.6t in total

[0037] (1) Smelting composition: C=0.12%, Si=0.34%, Mn=0.89%, P=0.013%, S=0.0025%; Alt=0.035%; refining slag basicity 6.1, white slag refining 31min, soft blowing 12min ;The tundish temperature is 1542°C (the superheat of molten steel in the tundish is 21°C), the casting speed is 2.3m / min; the electromagnetic stirring current of the crystallizer is 350A, the frequency is 4Hz, the electromagnetic stirring current at the end is 500A, and the frequency is 12Hz; The cross-sectional size of the billet is 150mm×150mm.

[0038] (2) Heating temperature: 1110-1145°C; starting rolling temperature: 980-1010°C; finishing rolling temperature: 945-965°C; rolling speed 85m / s; spinning temperature: 870-884°C; roller table speed 0.15m / s s; The damper of the fan is fully closed, and the insulation cover is fully closed except for 1#.

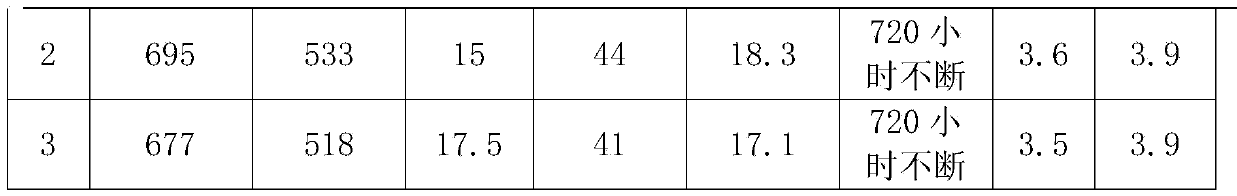

[0039] The results of the SSC test are as follows:

[0040]

[0041] Note: The stress c...

Embodiment 3

[0048] Embodiment 3: Specification: φ14mm1 furnace, 99.89t in total

[0049] (1) Smelting composition: C=0.06%, Si=0.22%, Mn=0.79%, P=0.012%, S=0.0021%; Alt=0.023%; refining slag basicity 6.0, white slag refining 32min, soft blowing 13min ;The tundish temperature is 1543°C (the superheat of molten steel in the tundish is 22°C), the casting speed is 2.4m / min; the electromagnetic stirring current of the crystallizer is 350A, the frequency is 4Hz, the electromagnetic stirring current at the end is 500A, and the frequency is 12Hz; The cross-sectional size of the billet is 150mm×150mm.

[0050] (2) Heating temperature: 1110-1140°C; starting rolling temperature: 975-1010°C; finishing rolling temperature: 935-975°C; rolling speed 85m / s; spinning temperature: 865-878°C; roller table speed 0.15m / s s; The damper of the fan is fully closed, and the insulation cover is fully closed except for 1#.

[0051] The results of the SSC test are as follows:

[0052]

[0053] Note: The stress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com