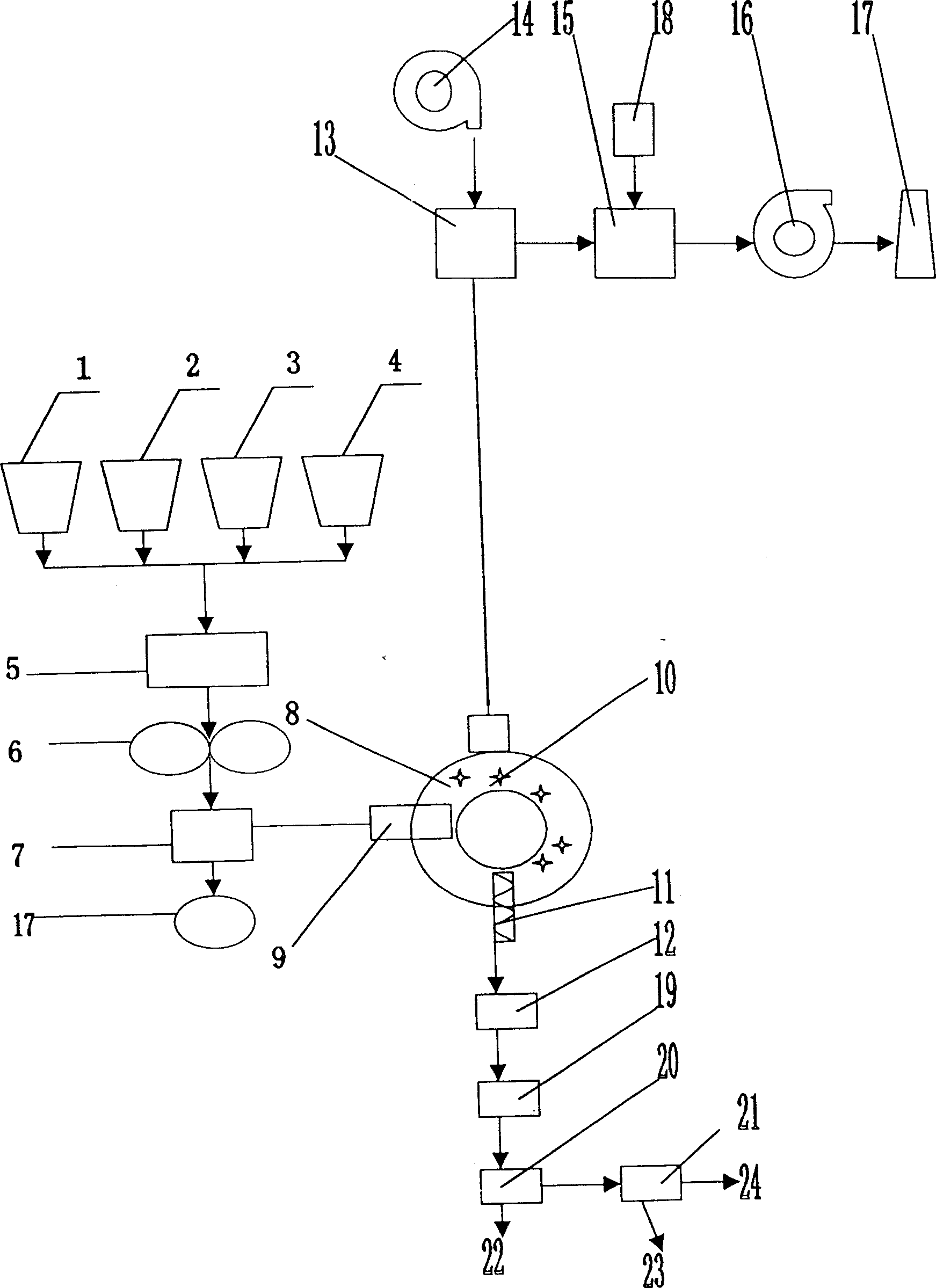

Coal base hot-air rotary hearth furnace melting reduction iron-smelting method

A technology of rotary hearth furnace and hot air, which is applied in the direction of fluidized bed furnace, etc., and can solve the shortage of raw materials for electric arc furnace steelmaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

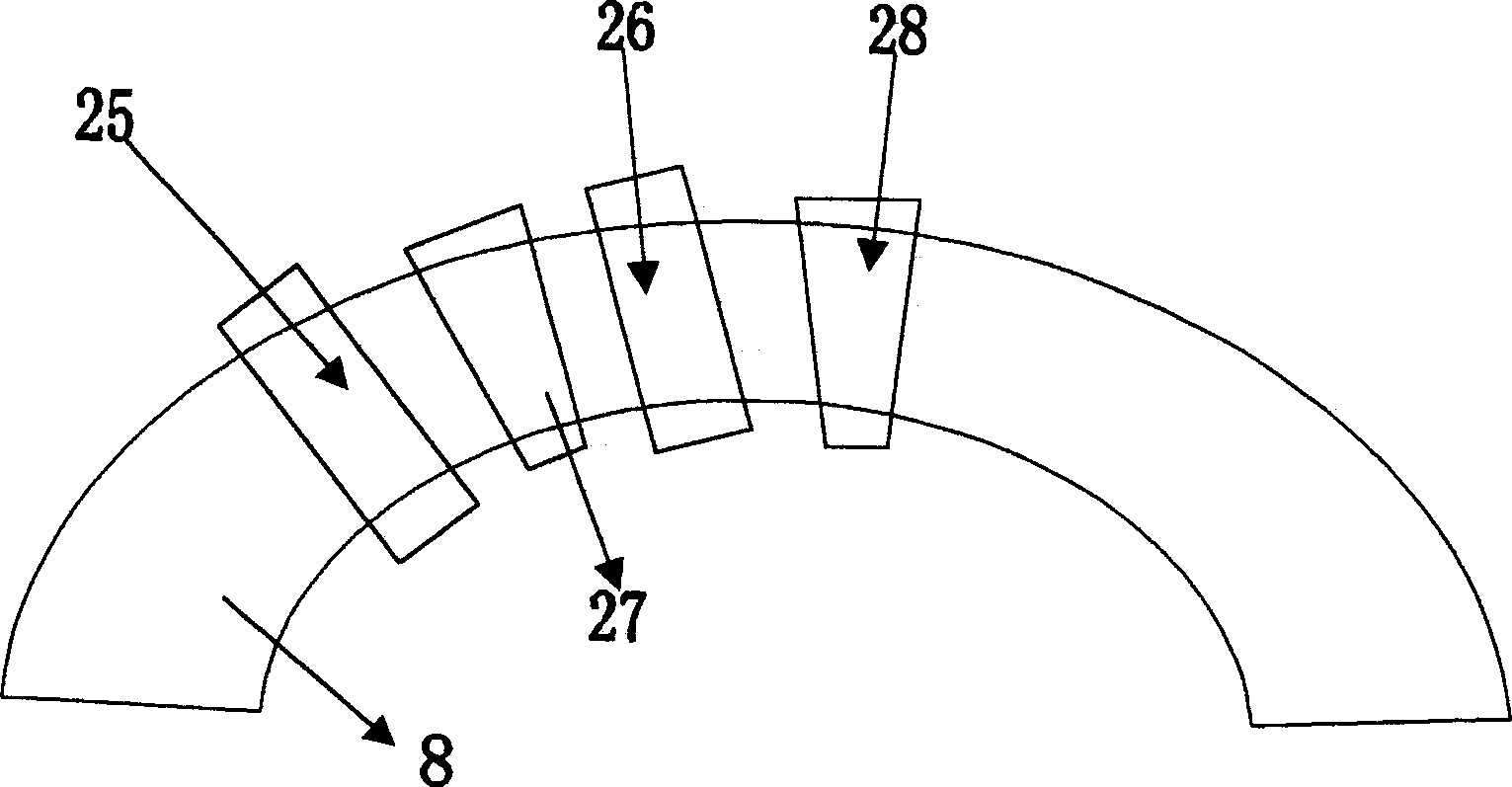

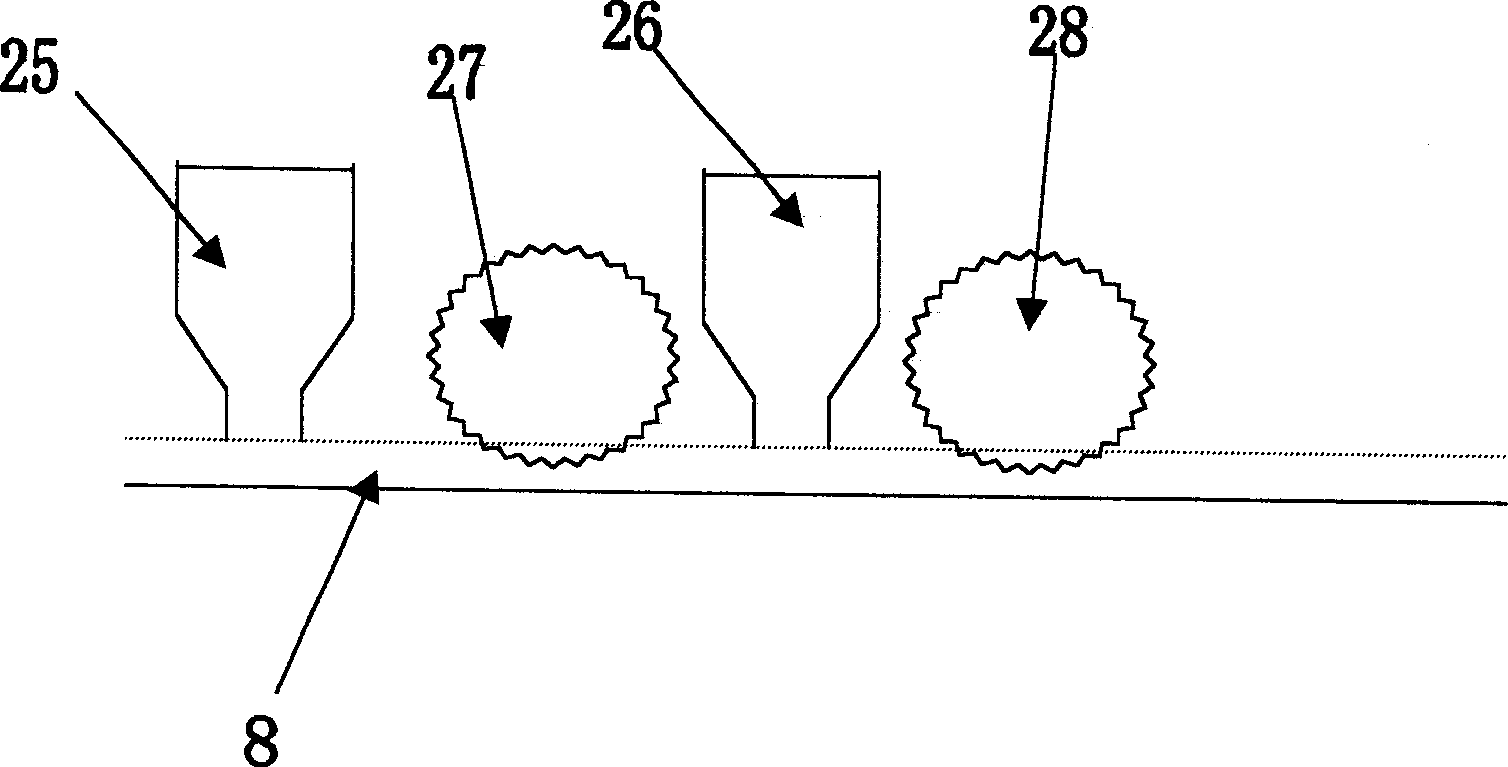

Method used

Image

Examples

Embodiment 1

[0023] 73 parts (weight, the same below) of iron ore powder (containing iron 62%), 18 parts of coal powder (12% of ash, 0.75% of sulfur), 8 parts of limestone powder (CaO 62%), 5 parts of dolomite powder (CaO+MgO=70%) and 3 parts of binder to make pellets. The particle size of the above-mentioned powder is that the particle size of the medium mineral powder is 150 mesh, and the composition of the binder is composed of 85% bentonite and 15% dextrin.

[0024] The prepared pellets are smelted and reduced in a rotary hearth furnace. The temperature of the preheating section of the furnace is 1000-1200°C, the temperature of the reducing section is 1300-1500°C, the temperature of the holding section is 1200-1400°C, and the temperature of the cooling section is 1300-1100°C. The processing time of the pellets in each of the above paragraphs was 5 minutes, 10 minutes, 5 minutes and 5 minutes respectively.

[0025] The reduced pellets are released at a temperature of about 1000°C, coo...

Embodiment 2

[0028] 75 parts (weight, the same below) of iron ore powder (62% iron content), 28 parts of coal powder (12% ash, 0.84% sulfur), 8 parts of limestone powder (CaO=60%), 5 parts of Baiyun Stone powder (CaO+MgO=65%) and 3 parts of binder are mixed evenly. The particle size of the powder and the composition of the binding agent are the same as in Example 1. The mixture is then fed into a rotary hearth furnace with agglomeration function to form agglomerates with a size of 25-50 mm.

[0029] Treat this agglomerate with other process identical with embodiment, obtain the pearl iron of > 5mm as a result, it contains the iron of 93%, the carbon of 2.9%, the sulfur of 0.065%, the silicon of 0.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com