Electric transmission control method of tilting of rotating furnace

A control method and electrical technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of cumbersome master-slave switching and poor torque balance, so as to reduce the amount of manual maintenance, achieve good torque balance, The effect of simplifying operation steps and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

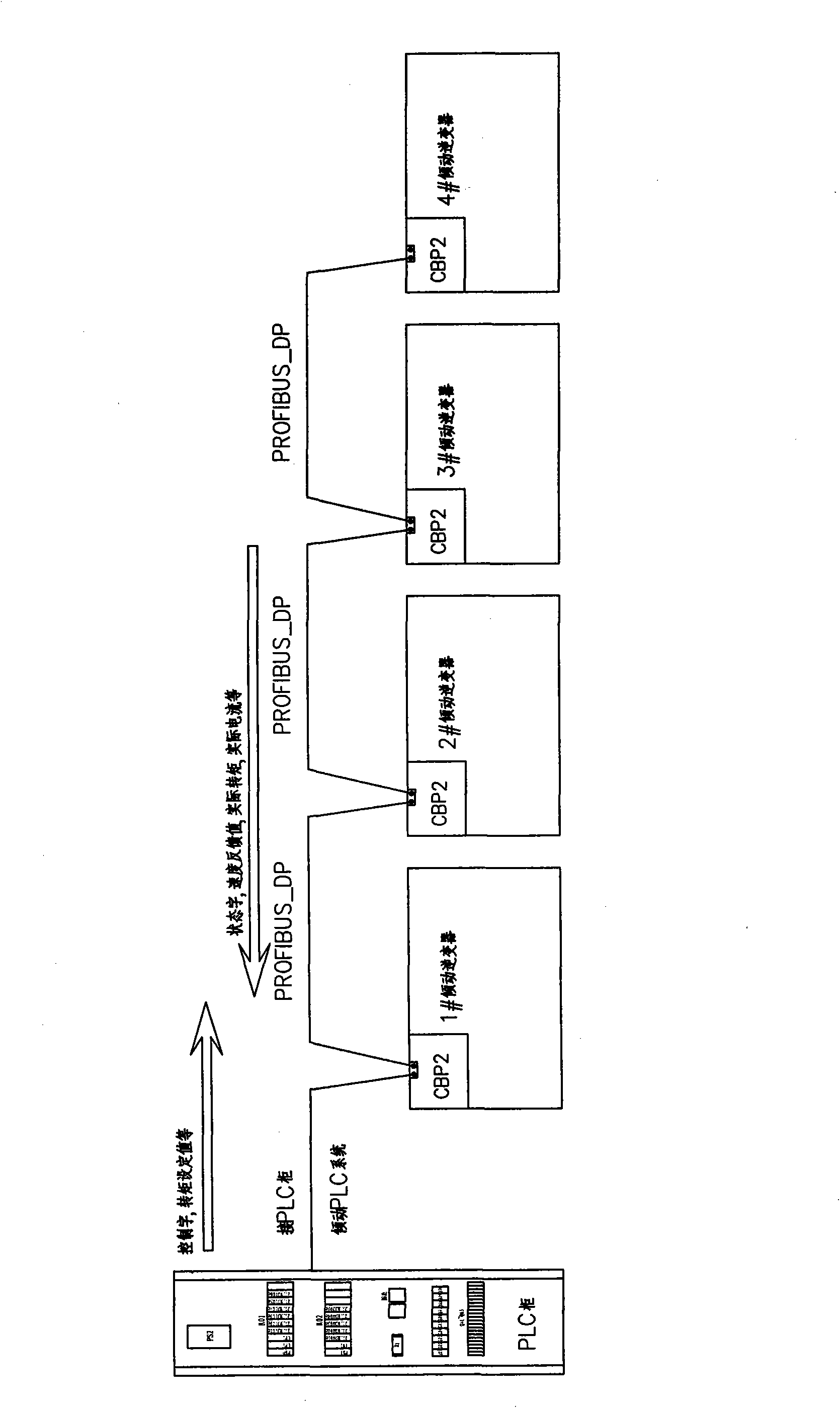

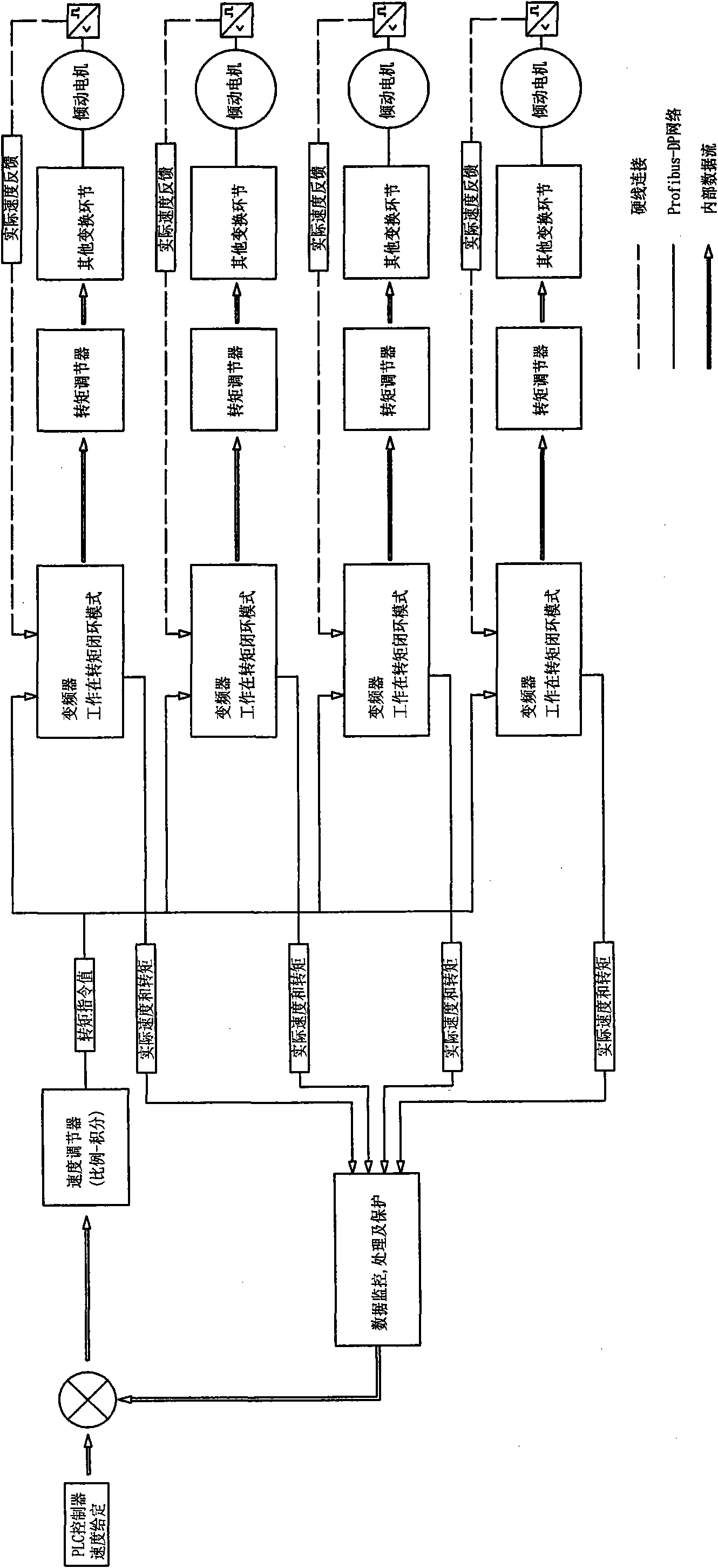

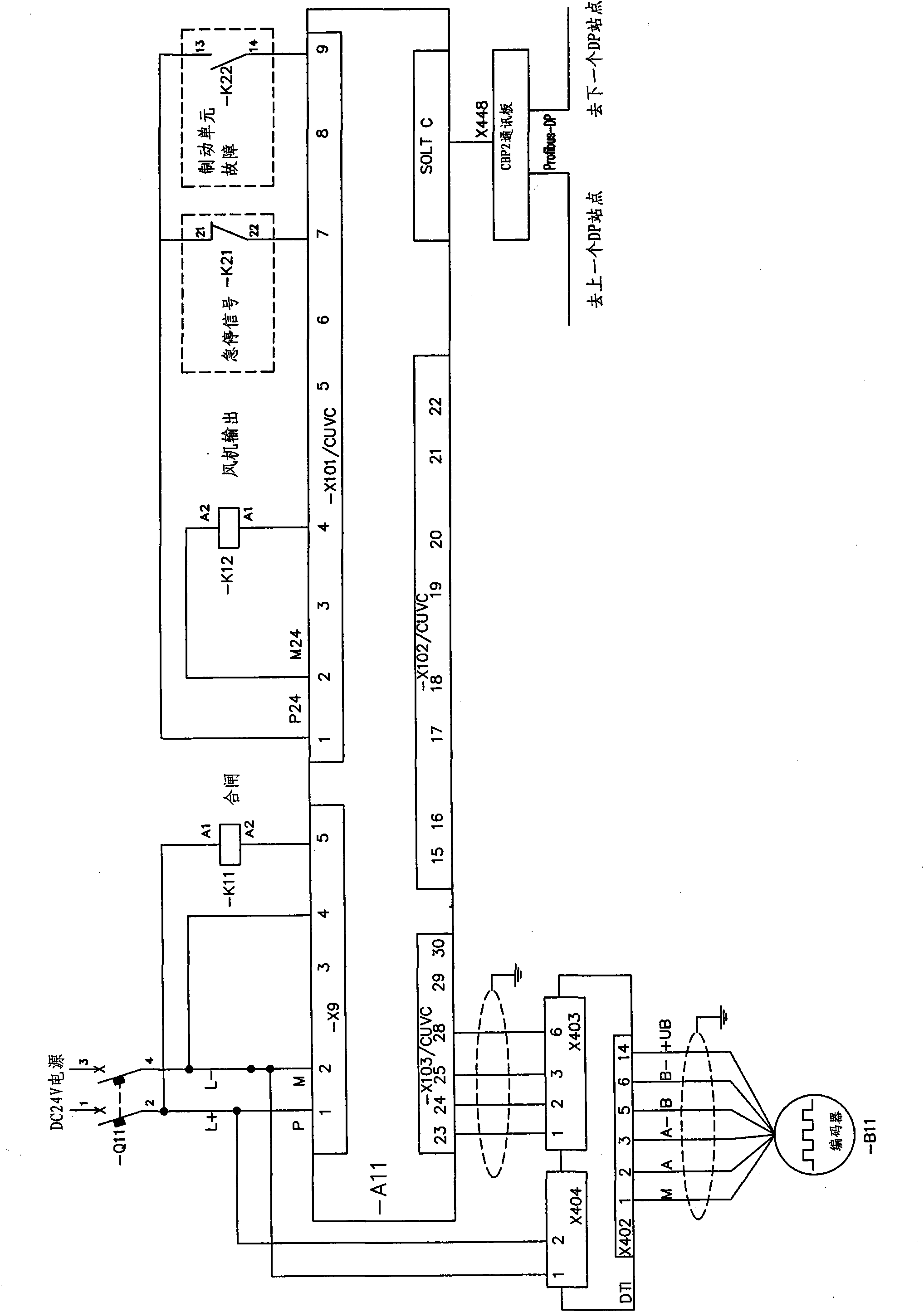

[0026] Such as figure 1 As shown, the electric transmission control system for converter tilting includes PLC (programmable logic controller) controller, multiple frequency converters and tilting speed encoders, which are connected by PROFIBUS-DP (distributed peripheral equipment process field bus) bus together. Each frequency converter controls its corresponding motor. Such as figure 2 As shown, the inverter can use Siemens 6SE70 inverter, and the inverter is connected to the PROFIBUS-DP bus through the CBP2 communication board.

[0027] The control method of the above-mentioned control system comprises the following steps:

[0028] 1) Configure the PROFIBUS-DP network, and then run the control system;

[0029] 2) The PLC controller sends the torque command value to the frequency converter through the speed regulator set by its internal program, and the frequency converter then adjusts its corresponding motor according to the command;

[0030] 3) The tilting speed encod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com