High-intensity quake-resistant steel bar for buildings and manufacturing method thereof

A manufacturing method and construction technology, applied in the field of construction steel, can solve the problems of low elongation, low strength of steel products and high cost, achieve high-strength plastic product seismic performance, excellent seismic performance, and reduce social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

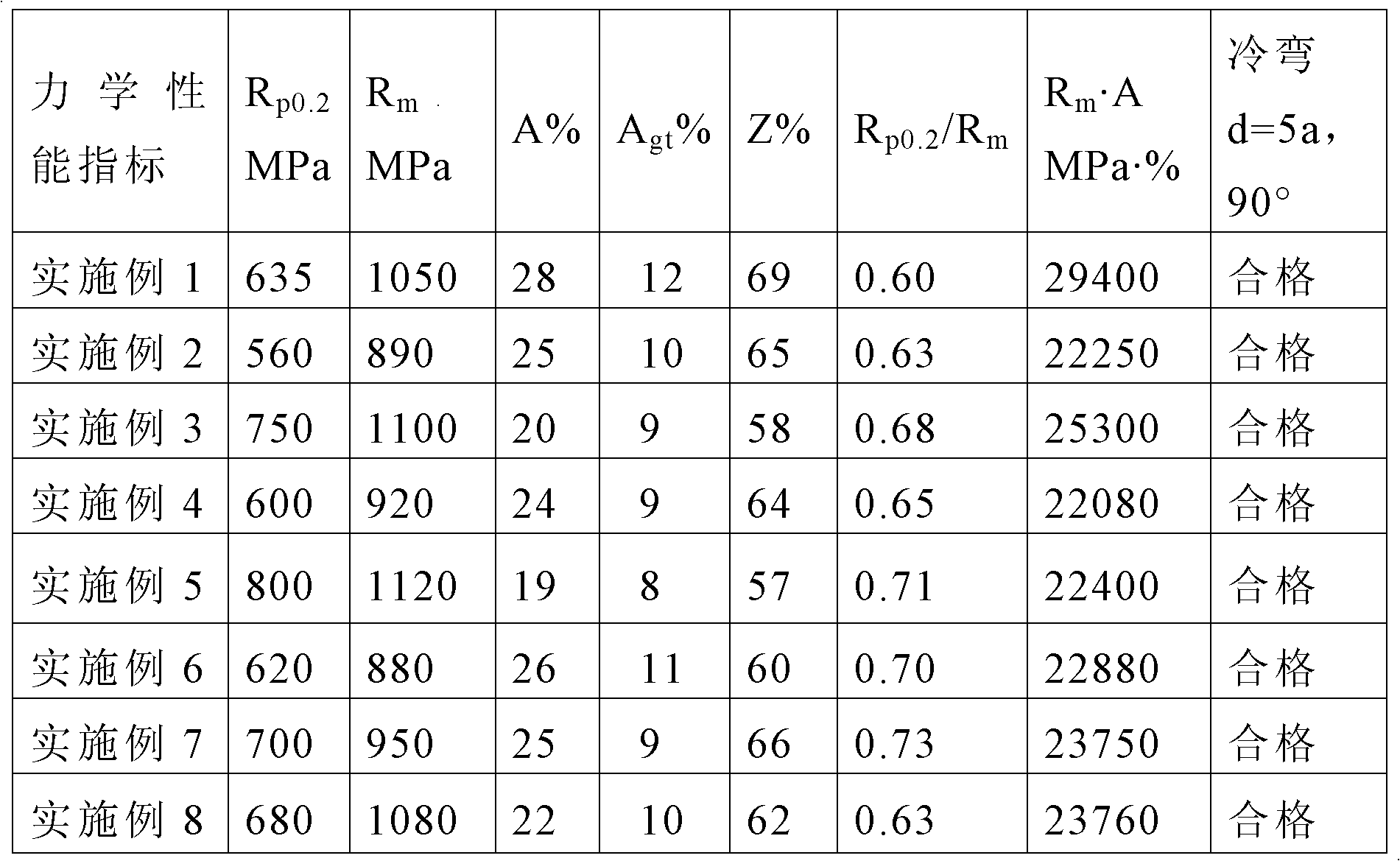

[0019] The high-strength earthquake-resistant building steel bar and its manufacturing method of the present invention will be further described in detail below in conjunction with specific embodiments.

[0020] Table 1 lists the chemical components in weight percentages of steel bars for construction in Examples 1 to 8 of the present invention (the balance is Fe and unavoidable impurities).

[0021] Table 1

[0022] Numbering

C

Si

mn

P

S

Al

Example 1

0.185

1.49

1.60

0.015

0.015

0.15

Example 2

0.212

0.50

1.55

0.018

0.016

1.25

Example 3

0.172

1.43

1.12

0.012

0.010

0.20

Example 4

0.189

0.80

1.45

0.012

0.011

1.30

Example 5

0.148

1.12

1.36

0.013

0.009

0.45

Example 6

0.140

1.00

1.25

0.016

0.020

0.10

Example 7

0.206 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com