Method for producing reduced iron compact in rotary hearth reducing furnace, reduced iron compact, and method for producing pig iron using the same

A kind of technology of rotary hearth and manufacturing method, applied in the field of manufacturing pig iron and reduced iron forming body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

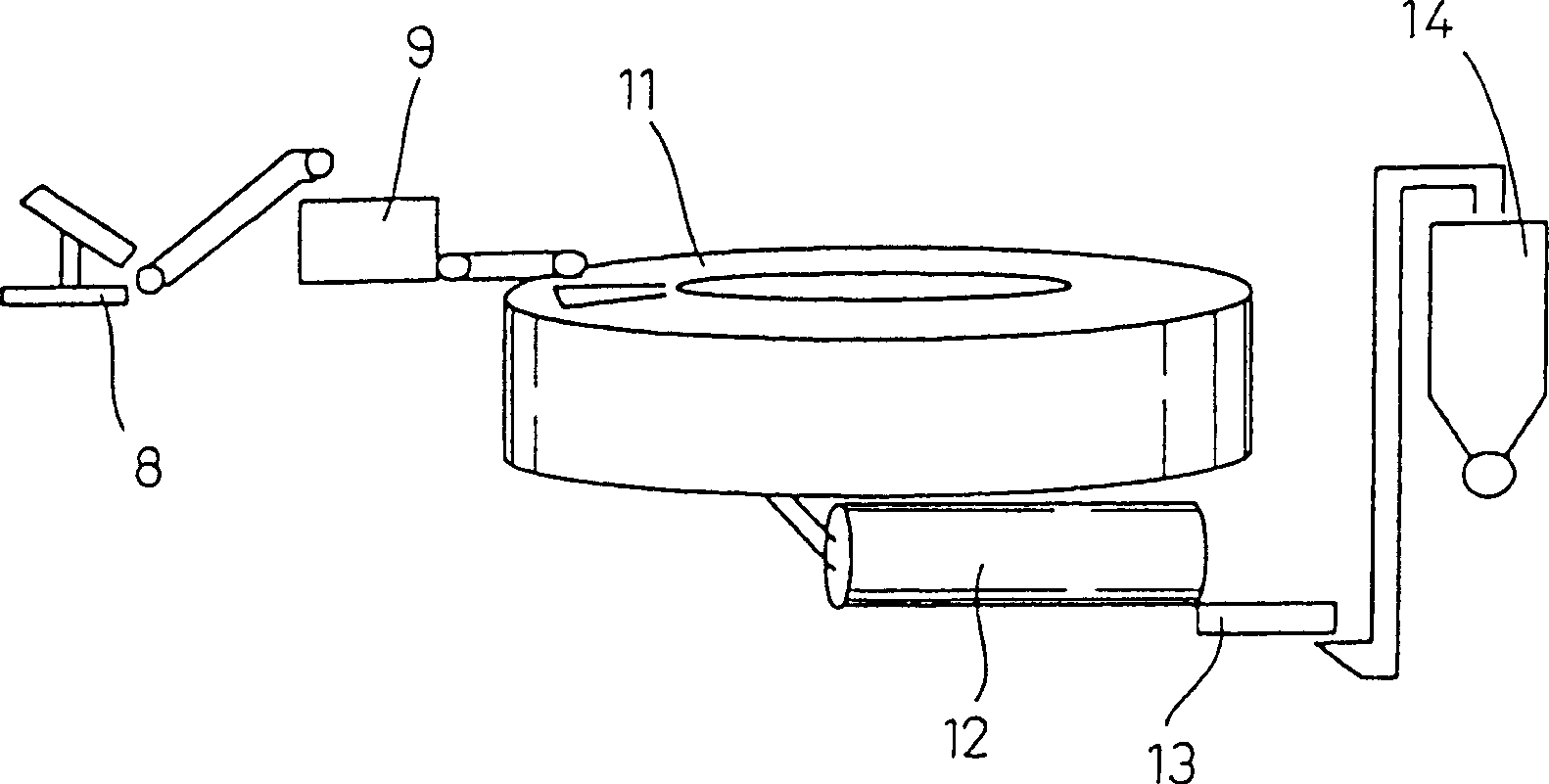

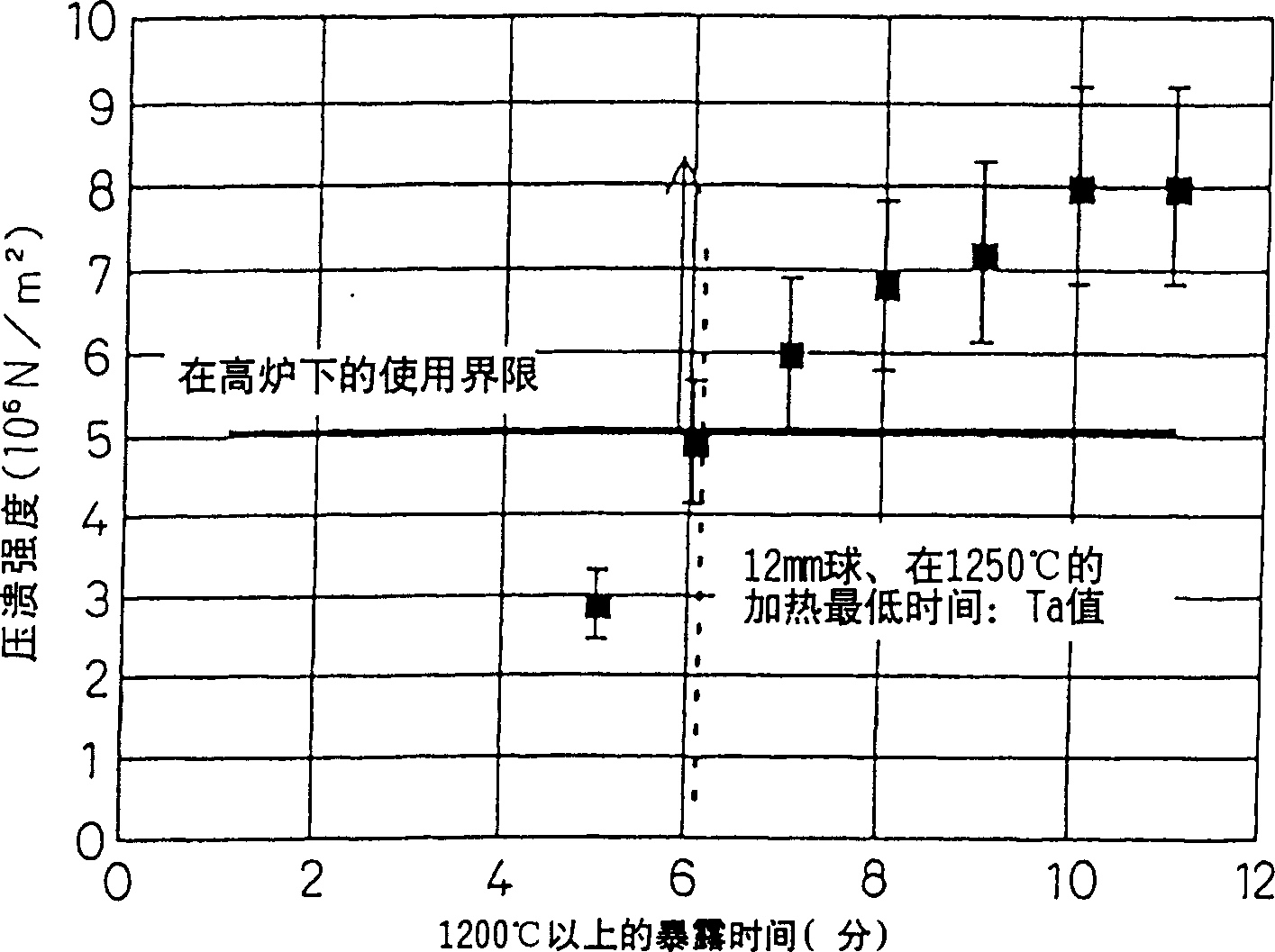

[0109] figure 1 The result of working using the rotary hearth type reduction furnace shown is shown. This facility is for manufacturing reduced iron pellets for blast furnaces at a rate of 15 tons per hour.

[0110] The raw material powder is a powder mixed with finely powdered iron ore (pellet raw material), converter gas dust, and fine coke. The total iron ratio is 54% by mass, the carbon ratio is 14% by mass, and the atomic molar ratio of carbon and active oxygen is is 1.05. This was manufactured into a molded body with a porosity of 23% by a molding device (pan granulator) 8 . The average particle size is 13mm (volume 1150mm 3). It was dried to a moisture content of 1% by mass, heated in a heating zone in a rotary hearth type reduction furnace 11, and then fired and reduced for 10 minutes at an average gas temperature of 1370° C. in the reducing zone. The number of laying layers of the molded body was 1.4. The reduced iron pellets obtained here were cooled with a rot...

Embodiment 2-5

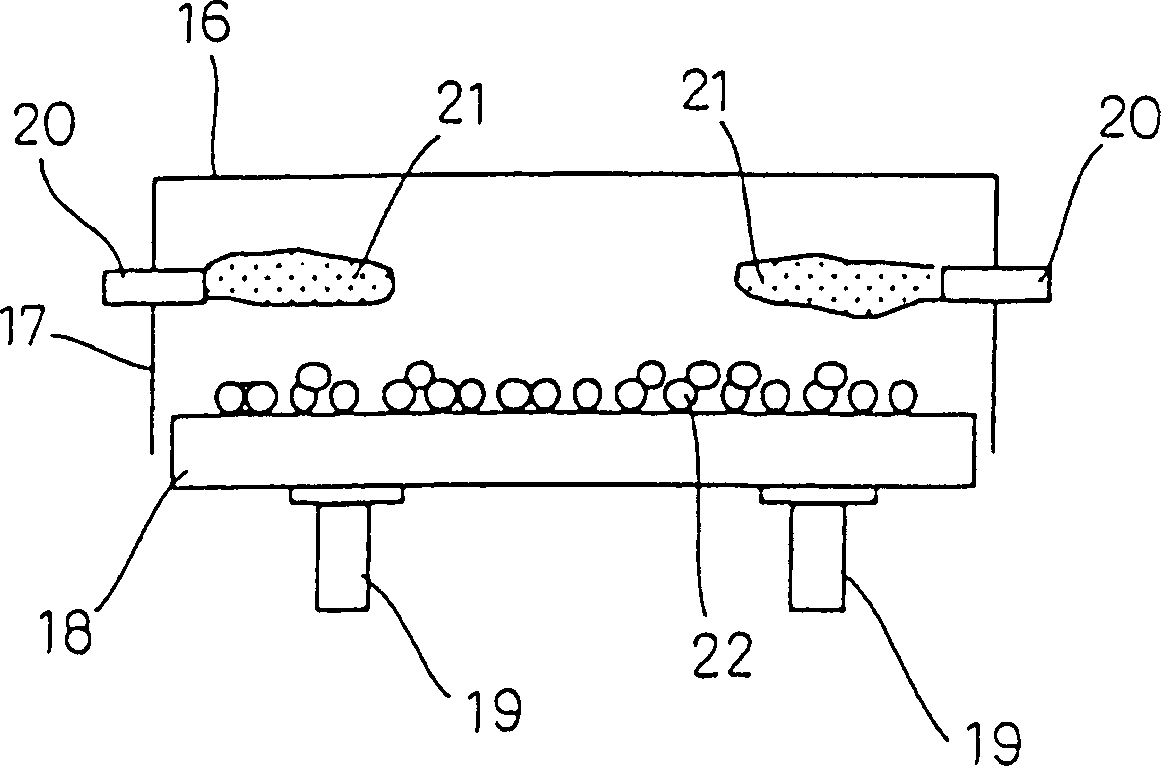

[0115] Illustrate adopting the method of the present invention, basically use Figure 7 The equipment of carrying out the operation result of the rotary hearth type reduction furnace of embodiment 2-5. Table 1 shows the results of the operation of restoring molded bodies molded by the three molding methods using the present invention. Example 2 is an operation example of reducing a molded body having a porosity of 24% with a ratio of ferric oxide of 55% by mass using a pan granulator. Example 3 is an operation example in which a molded body having a porosity of 30% produced by a block molding machine containing 63% by mass of ferric oxide was reduced. In addition, Example 4 is an operation example of reducing a cylindrical molded body with a porosity of 43% produced by an extrusion molding machine containing 82% by mass of ferric oxide. Also, in Example 5, the converter dust with an average particle diameter of 2.9 μm containing 75% by mass of ferric oxide and containing met...

Embodiment 2

[0117] In Example 2, the porosity is higher than the appropriate porosity V1 value calculated from the ratio of ferrous oxide: 18%. As a result, the pulverization rate of the molded body during reduction was 6.9%, and the average metal ratio of the reduced iron molded body and the powdered reduced product was also as high as 83%. In Example 3, the porosity is higher than the appropriate porosity V1 value calculated from the ratio of ferrous oxide: 23%. As a result, the pulverization rate of the molded body during reduction was 5.8%, and the average metal ratio of the reduced iron molded body and the powdered reduced product was also as high as 85%. In addition, the porosity of the molded body of Example 4 was very high at 43%, and even if the ratio of ferric oxide was 82% by mass and the appropriate porosity V1 value was 33%, the pulverization of the molded body was very little, Just 3.3%. Moreover, the metallization rate of the molded article was also very good at 87%.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com