Evaporator

A technology of evaporator and heat exchanger, which is applied in the field of concentrated liquid concentration devices in the chemical industry, and can solve problems such as low thermal efficiency, high energy consumption, and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

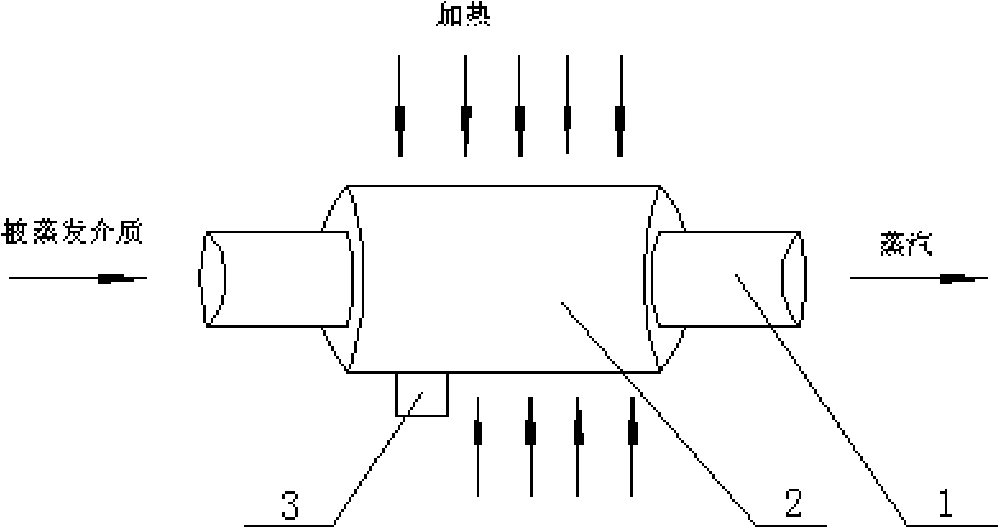

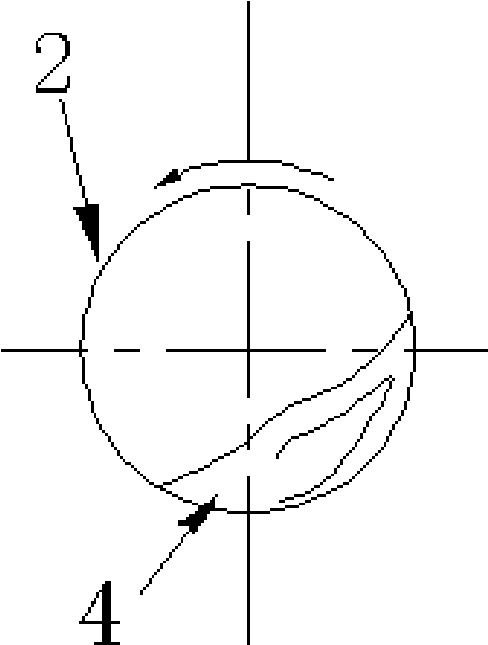

[0015] Specific embodiment 1 of the present invention, an evaporator, including a heating chamber and a heat exchanger installed in the heating chamber, the heating chamber has a high-temperature gas inlet and a gas outlet, and a heat exchange cylinder 2 is installed in the heating chamber, and the heat exchange cylinder 2 There are hollow shafts 1 communicating with the inside of the heat exchange cylinder 2 at both ends respectively, the two hollow shafts 1 are coaxial, and an openable and closable discharge port 3 is provided on the cylinder wall of the heat exchange cylinder 2 (for example, in the discharge There is an opening and closing valve on the mouth), and a driving device is installed outside the heating room, and the driving device drives the heat exchange cylinder 2 to rotate through the transmission parts, such as figure 1 shown. The transmission part can be a ring gear set on the hollow shaft 1 and a gear meshed with the ring gear; it can also be a sprocket and...

specific Embodiment 2

[0018] Specific embodiment 2 of the present invention, a kind of evaporator, its structure is similar to embodiment 1, is used in the soda sulfide production process. The heating chamber is built with a brick-concrete structure, with a height of about 3-4 meters. The top can be made of brick-concrete structure or steel plate. The diameter of the heat exchange cylinder is between 2 and 8 meters. The heating chamber is located in the converter for alkali sulfide production. In addition, the high-temperature gas inlet is connected to the high-temperature waste flue gas outlet discharged from the alkali sulfide production converter, and the high-temperature waste flue gas discharged from the converter is used to heat, evaporate and concentrate the rotary heat exchange cylinder containing the evaporated medium inside.

[0019] The energy consumption comparison between the evaporator in Example 2 and the original sulfide production evaporation equipment is shown in Table 1.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com