Trajectory based control of plasma processing

a technology of trajectory control and plasma processing, which is applied in the direction of individual semiconductor device testing, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of time-controlled multi-step etching with static set points and other desired processes or recipes of the prior art that may be considered too constraining, and the etching process of forming the contact structure of fig. 1 and most other etched structures is typically not straightforward,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

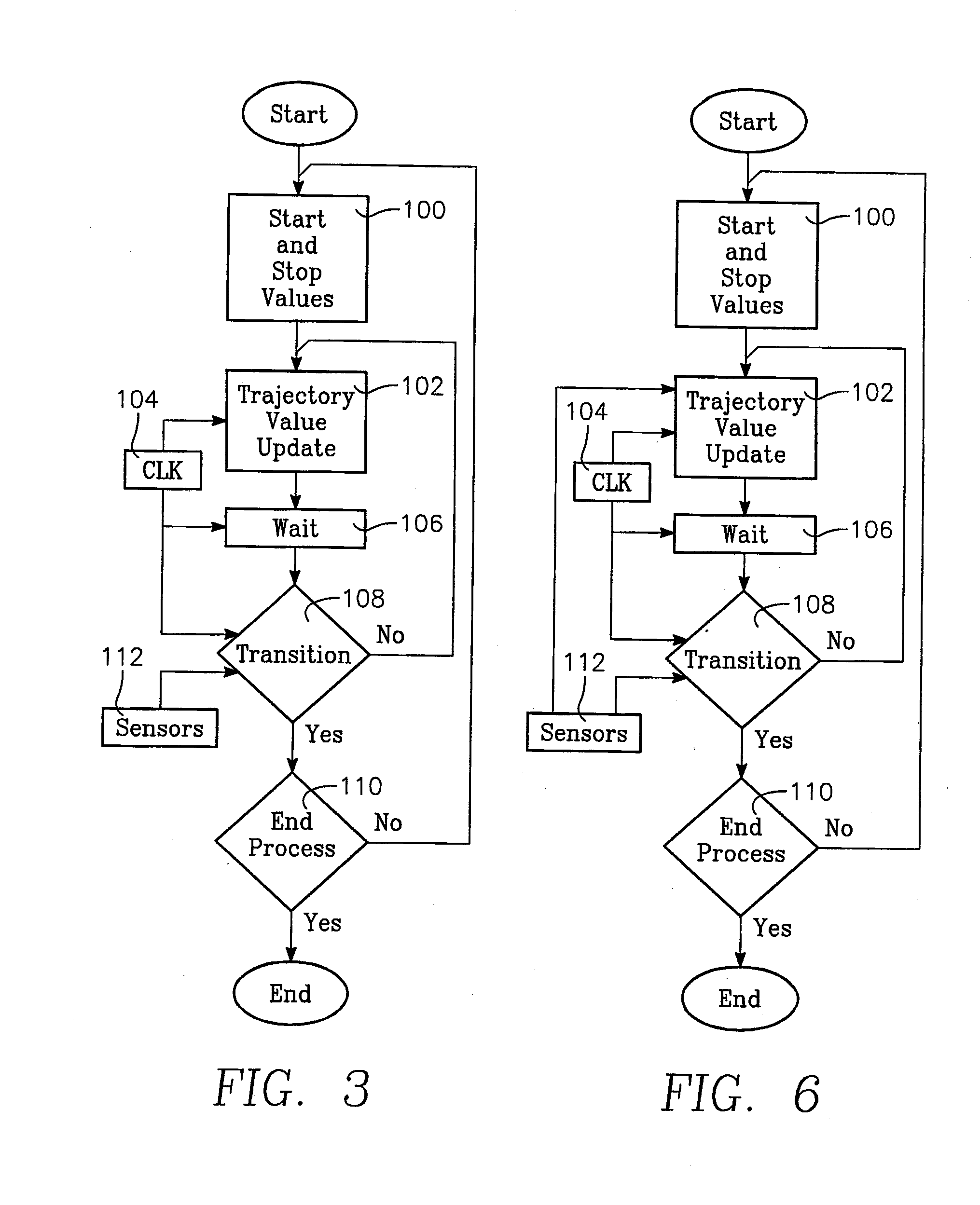

[0026]Embodiments of the present invention include a nearly continuous adjustment of process parameters rather than set levels of predetermined duration. A flow chart in FIG. 3 functionally illustrates an embodiment of the invention. At the start of processing a wafer, a set of start and stop values are provided at an initial values step 100. In one embodiment, a first phase of the process is selected for all controlled parameters such as chamber pressure, power levels, gas flows and the like. In one embodiment, the start and stop values represent the values of the controlled parameters at the beginning and end of the processing phase. The values are updated according to predetermined trajectories for each of the controlled parameters at an update step 102. In one embodiment, the start and stop values and the trajectories are stored in a controller memory as the recipe for the wafer process being practiced. The updating depends upon the elapsed time since the beginning of the phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| trajectories | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com