Pulsation CO2 foam fracturing and evaluation simulation integrated test device and method

A test device and foam technology, applied in teaching models, mining fluids, earthwork drilling, etc., can solve problems such as increasing gas diversion channels, fracturing fluid pollution to water resources, and inability to realize unconventional natural gas commercial exploitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below.

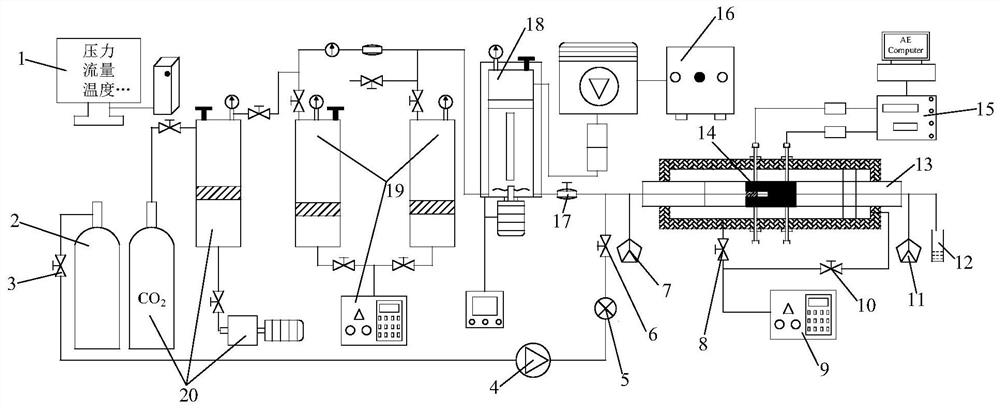

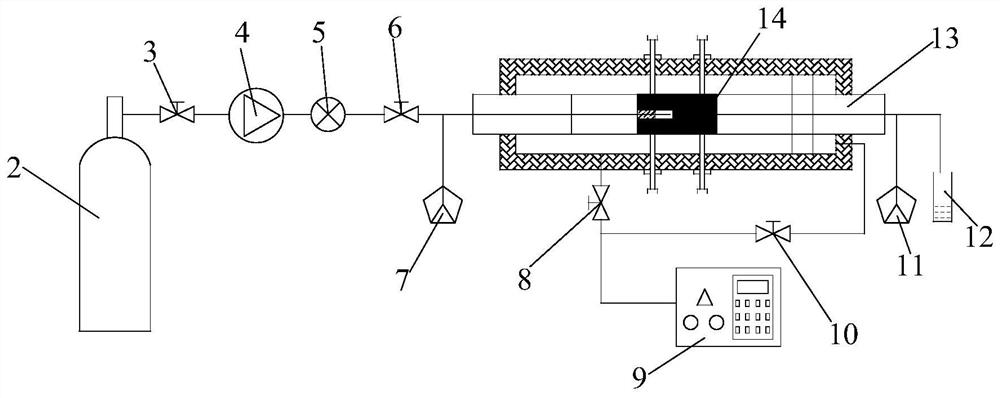

[0043] Such as figure 1 As shown, a pulsating CO 2 Foam fracturing and evaluation simulation integrated test device, including data acquisition and control system 1, permeability measurement system, three-axis core holder 13, acoustic emission monitoring system 15, pulsation fracturing control system 16, high temperature and high pressure foam performance evaluation system 18. Foam fracturing fluid quantitative injection system 19 and CO 2 Pressurized liquefaction system 20;

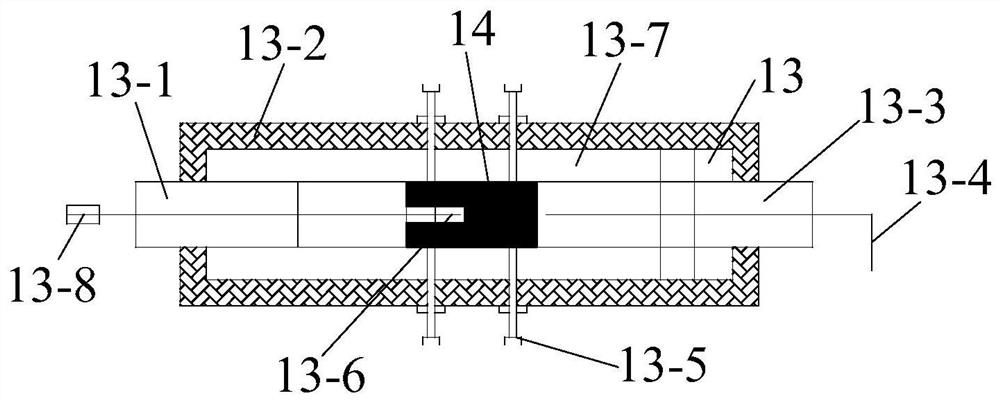

[0044] Such as Figure 3 to Figure 5 As shown, the triaxial core holder includes a holder main body 13-7, an advection pump 9, a left side plug 13-1, a right side plug 13-3 and a plurality of acoustic wave conducting rods 13-5, The holder main body 13-7 is provided with a three-axis loading mechanism, and the rock core sample 14 is arranged in the three-axis loading mechanism, and the rock core sample 14 is provided with a drill hole; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com