Lab simulation testing device for staged fracturing of horizontal well, and operation method for same

A technology of staged fracturing and simulation test, applied in the field of hydraulic fracturing theory and technology research, can solve the problems of affecting test accuracy, complex operation, poor flexibility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

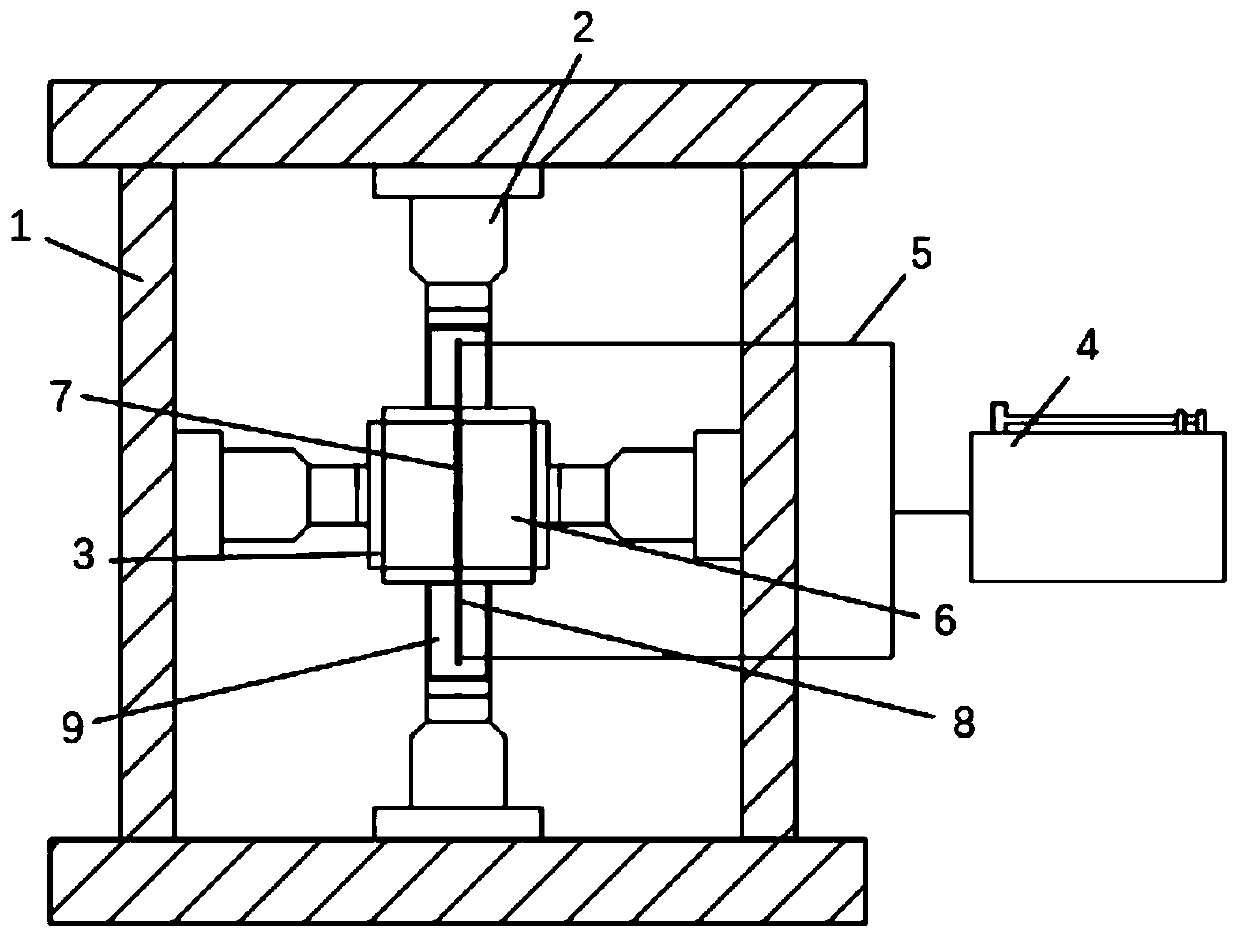

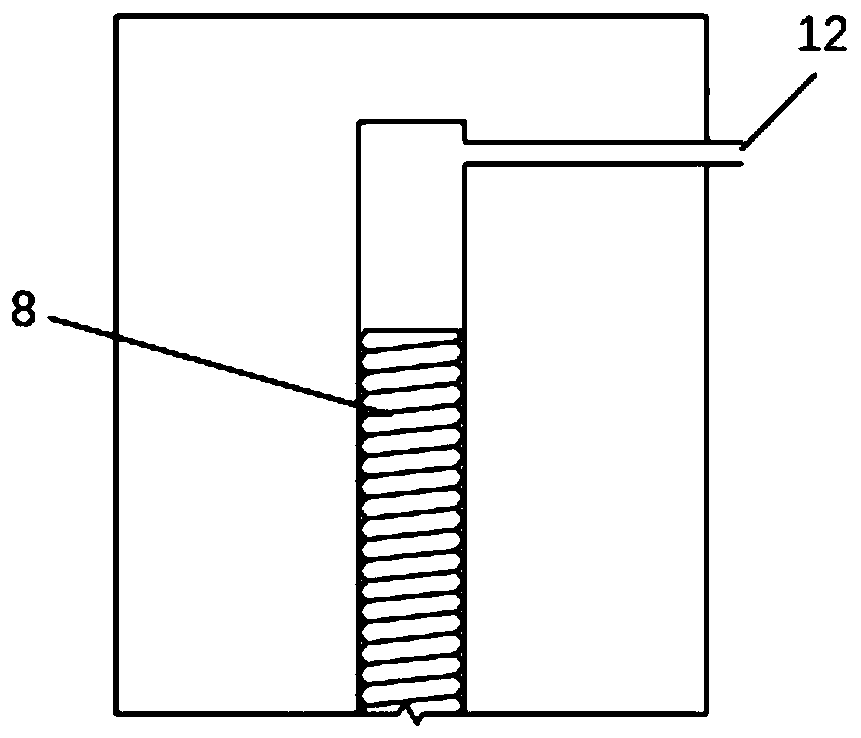

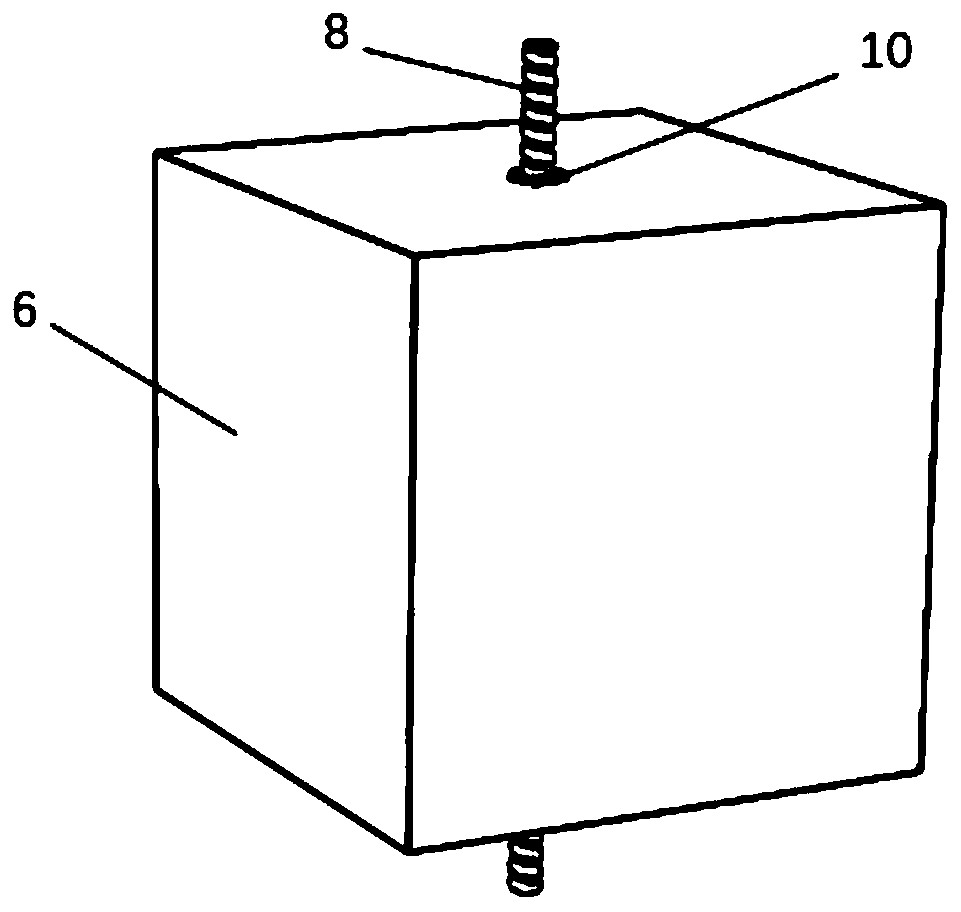

[0042] Attached below Figure 1-Figure 6 The present invention is described in detail, specifically, the structure is as follows:

[0043] This embodiment provides an indoor simulation test device for staged fracturing of a horizontal well, including a triaxial loading unit, a fracturing control unit, and a hydraulic loading unit. The triaxial loading unit is used to provide the pressure on the test piece. The hydraulic loading unit is used to pump fracturing fluid into the simulated horizontal well, and the fracturing control unit is used to adjust and control the fracturing mode, which is connected with the hydraulic loading unit.

[0044] The triaxial loading unit includes a test frame 1, a plurality of loading cylinders 2 and a pressure bearing plate 3. The test frame 1 is used to provide reaction force and has a frame structure; the loading cylinders 2 are fixedly connected to the test frame 1 through connectors. In this embodiment, there are six loading cylinders 2, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com