Feeding-controlling full-bore sliding sleeve sectional fracturing tube column

A staged fracturing, full-bore technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of high risk, high operating cost, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

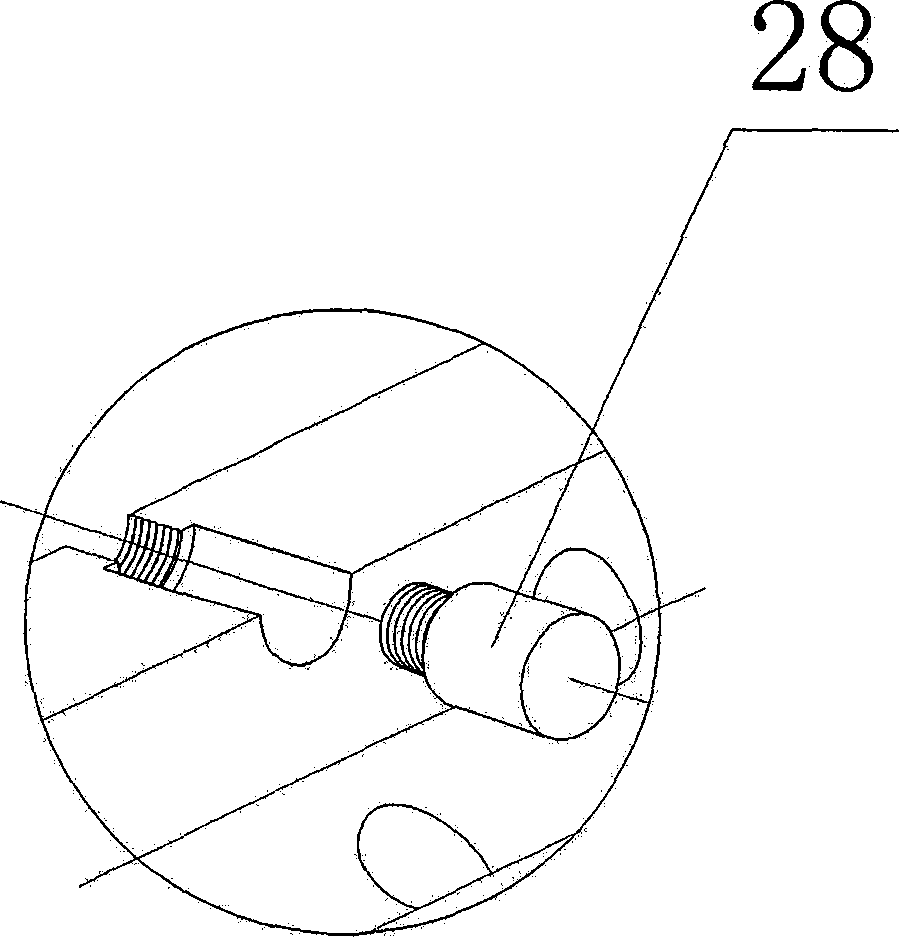

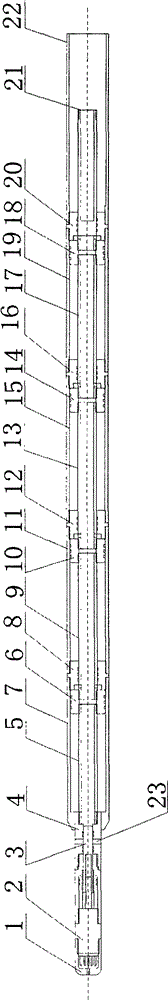

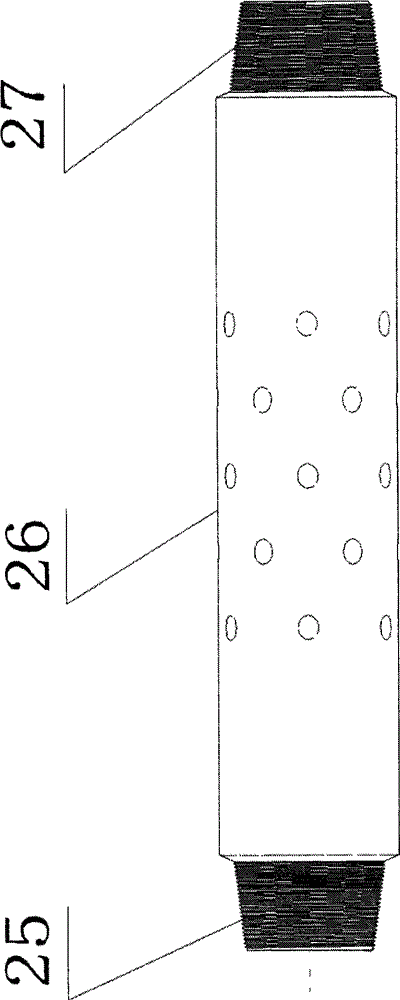

[0031] According to the oil and gas well (attached Figure 4 ) for segmental fracturing stages, set the number of plug control sliding sleeve groups, the bottom layer of which is equipped with a timing sliding sleeve 48, and other layers are assembled with plug control sliding sleeves 46 in each production section of the completion casing according to the sequence of fracturing positions, Establish the plug-controlled full-bore sliding sleeve staged fracturing string; since the plug-controlled sliding sleeve is not opened during well cementing, the cement is replaced to the design position in the traditional way. After the completion of cementing and other preparations, the first stage Carry out fracturing, and then use the cable 41, cable head 43, positioning instrument 44, and cable hydraulic plug delivery tool 45 to lower the high-strength hydrolysis bridge plug 47 to the second stage, and seal the bridge plug seat in the plug control sliding sleeve, Fracturing fluid is inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com