Fracture height-adjustable acid fracturing method adopting polyatomic acid and steering acid

A technology of acid fracturing and acid diversion, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc. It can solve problems such as short fractures, and achieve the effects of improving capacity, increasing effective length, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

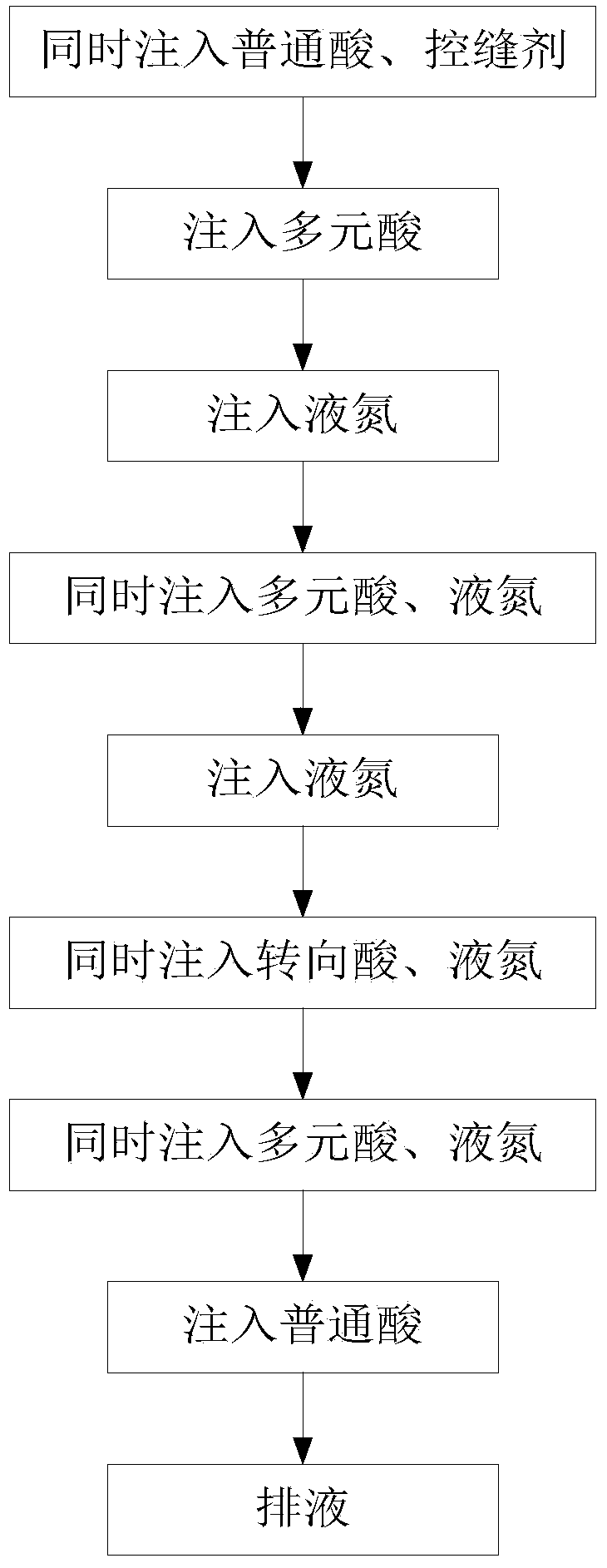

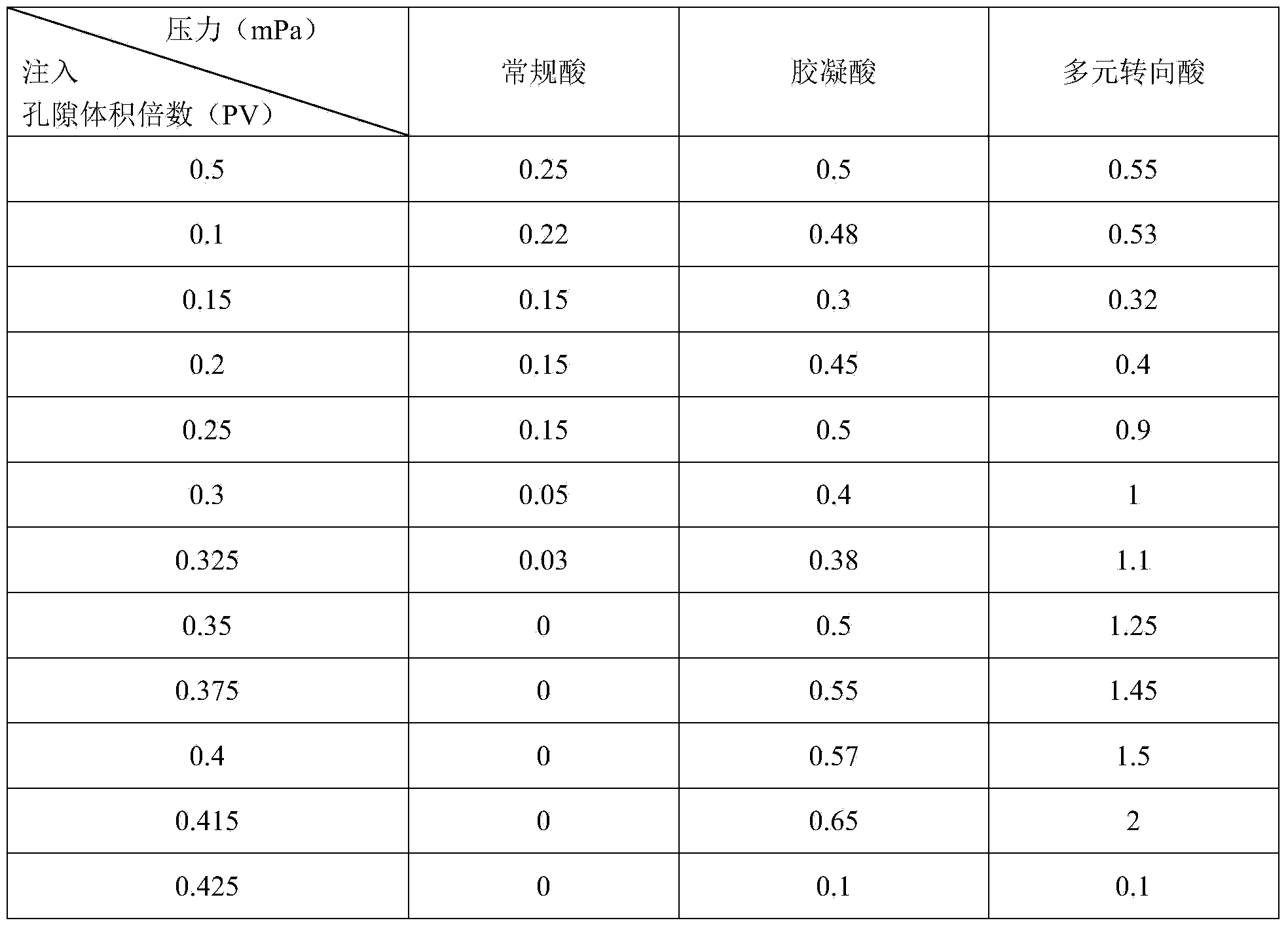

Method used

Image

Examples

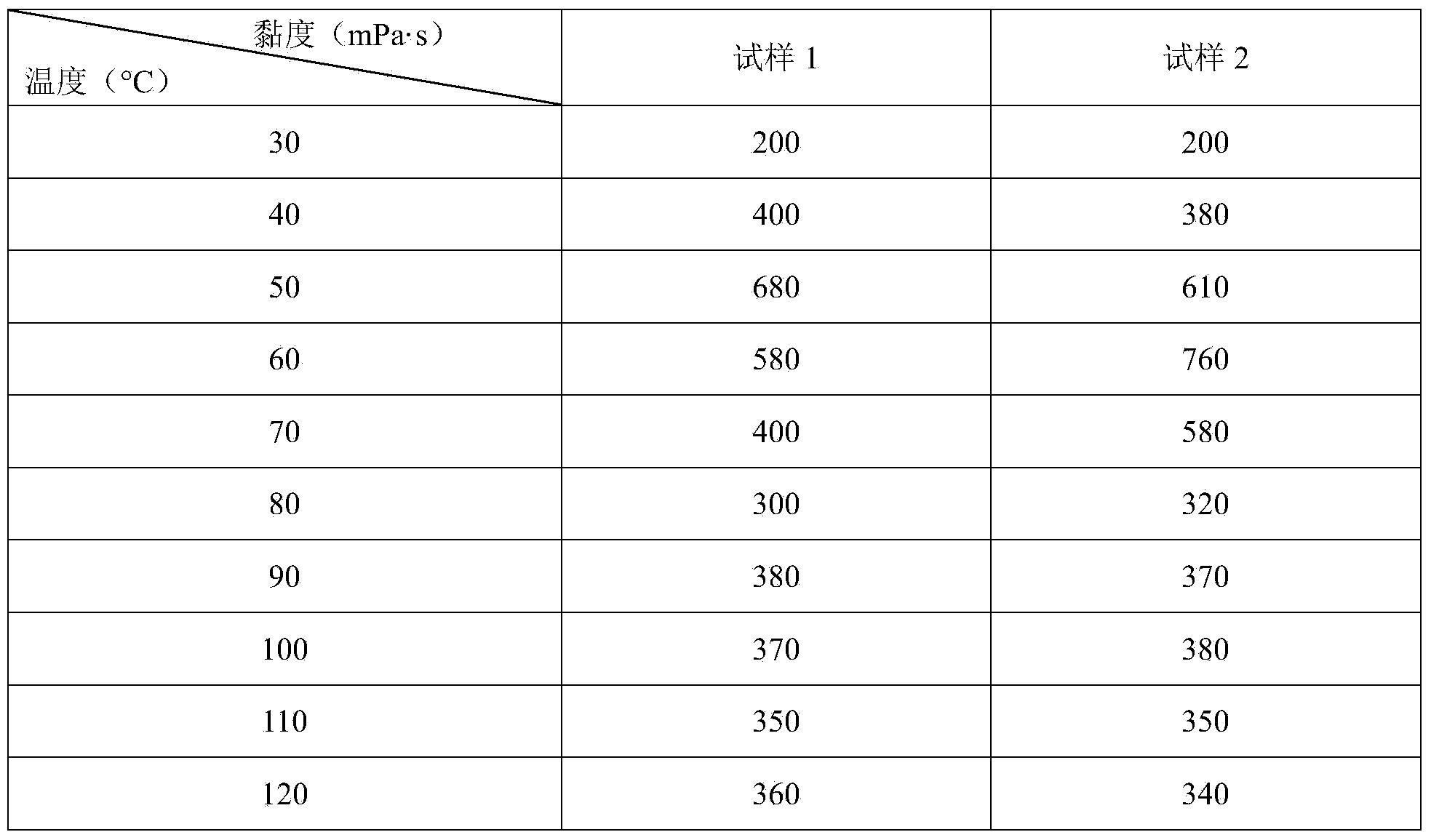

Embodiment 1

[0071] The polybasic acid in the polybasic acid-adjustable joint high-acidification fracturing method of the present invention takes the following raw materials by mass percentage: 70% of industrial hydrochloric acid with a mass concentration of 31%, 10% of formic acid with a mass concentration of 85%, CHS- 5 Acidified high-temperature corrosion inhibitor 1.5%, FRK-V180 high-temperature gelling agent 0.6%, TWJ acidified iron ion stabilizer 1.5%, SZJ-3 acidified fracturing aid drainage agent 0.3%, clear water 16.1%, the total content of the above components is 100%, the raw materials weighed above are added to the first acid tank, and then mixed by a pump truck;

[0072] The diverting acid in the multi-component diverting acid adjustable fracture high-acidification fracturing method of the present invention takes the following raw materials by mass percentage: 70% of industrial hydrochloric acid with a mass concentration of 31%, and 0.4% of CZD-2 repeated fracturing control and ...

Embodiment 2

[0077] The polybasic acid in the polybasic acid-adjustable seam high-acidification fracturing method of the present invention takes the following raw materials by mass percentage: 65% industrial hydrochloric acid with a mass concentration of 31%, 8% formic acid with a mass concentration of 85%, CHS- 5 Acidified high-temperature corrosion inhibitor 1%, FRK-V180 high-temperature gelling agent 0.4%, TWJ acidified iron ion stabilizer 1%, SZJ-3 acidified fracturing aid drainage agent 0.2%, clear water 24.4%, the total content of the above components is 100%, the raw materials weighed above are added to the first acid tank, and then mixed by a pump truck;

[0078] The diverting acid in the multivariate diverting acid adjustable fracture high-acidification fracturing method of the present invention takes the following raw materials by mass percentage: 75% of industrial hydrochloric acid with a mass concentration of 31%, and 0.6% of CZD-2 repeated fracturing control and diverting agent...

Embodiment 3

[0083] The polybasic acid in the polybasic acid-adjustable joint high-acidification fracturing method of the present invention takes the following raw materials by mass percentage: 80% of industrial hydrochloric acid with a mass concentration of 31%, 12% of formic acid with a mass concentration of 85%, CHS- 5 Acidified high-temperature corrosion inhibitor 2%, FRK-V180 high-temperature gelling agent 0.8%, TWJ acidified iron ion stabilizer 2%, SZJ-3 acidified fracturing aid drainage agent 0.4%, clear water 2.8%, the total content of the above components is 100%, the raw materials weighed above are added to the first acid tank, and then mixed by a pump truck;

[0084] The diverting acid in the multi-component diverting acid adjustable fracture high-acidification fracturing method of the present invention takes the following raw materials by mass percentage: 60% of industrial hydrochloric acid with a mass concentration of 31%, and 0.3% of CZD-2 repeated fracturing control and diver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com