Device for testing true triaxial hydraulic fracturing strain characteristic of rock

A technology of hydraulic fracturing and characteristic testing, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of complete functions, convenient operation, beautiful and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

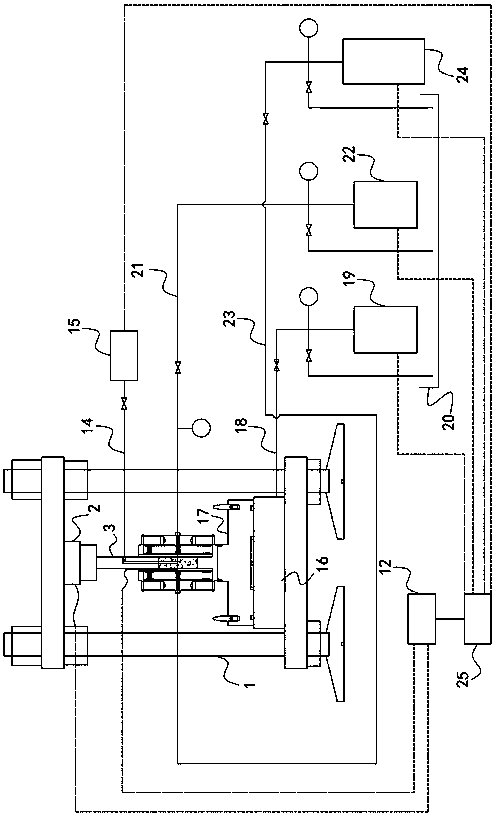

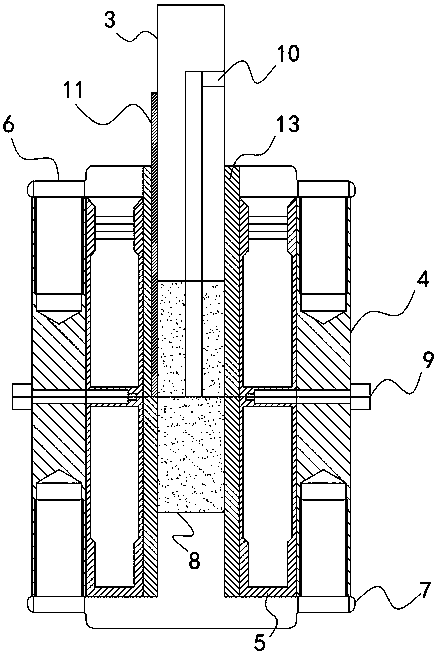

[0025] The technical solution of the present invention will be described in detail below through the embodiments and the accompanying drawings.

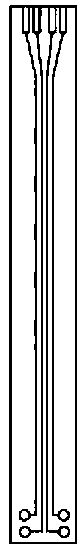

[0026] Such as Figure 1-3 As shown, a rock true triaxial hydraulic fracturing strain characteristic test device of the present invention includes a loading frame 1, an axial lifting mechanism, an axial load sensor 2, a hydraulic fracturing plug 3, a strain gauge 11, and a static strain gauge 12. True three-axis gripper, X-direction stress control system, Y-direction stress control system, hydraulic fracturing control system, the axial lifting mechanism is installed at the bottom of the loading frame 1, and the axial load sensor 2 is installed at the loading The upper part of the frame 1, and is located directly above the axial lifting mechanism;

[0027] Such as figure 2 As shown, the true three-axis holder includes a holder cylinder 4, a two-way loading liquid bag 5, an upper end cover 6, and a lower end cover 7. The holder cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com