Method for manufacturing micro-spring

A technology of micro-spring and oxide sol, which is applied in the direction of spring, micro-structure technology, micro-structure device, etc., can solve the problems of long cycle, complex processing technology, large equipment investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

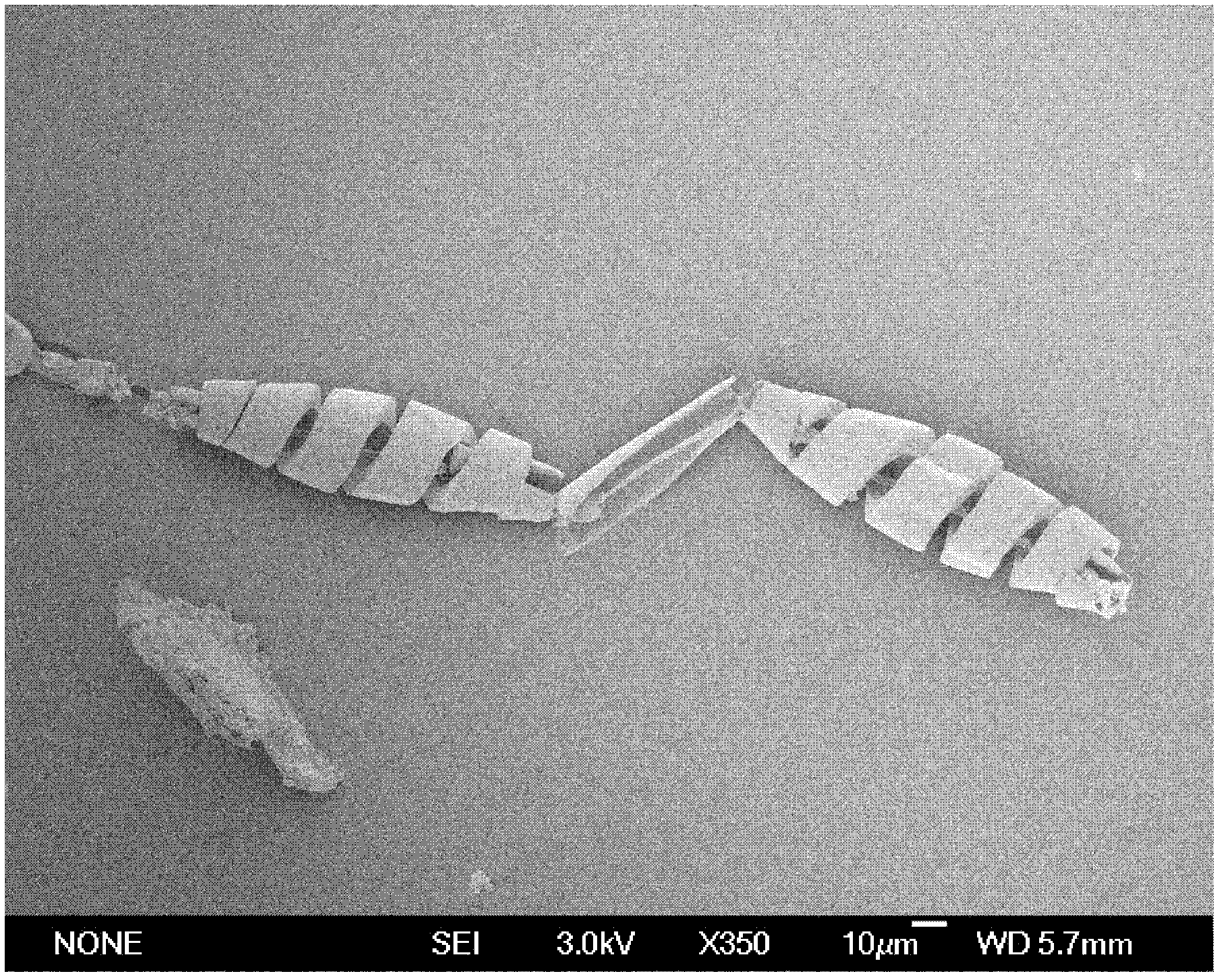

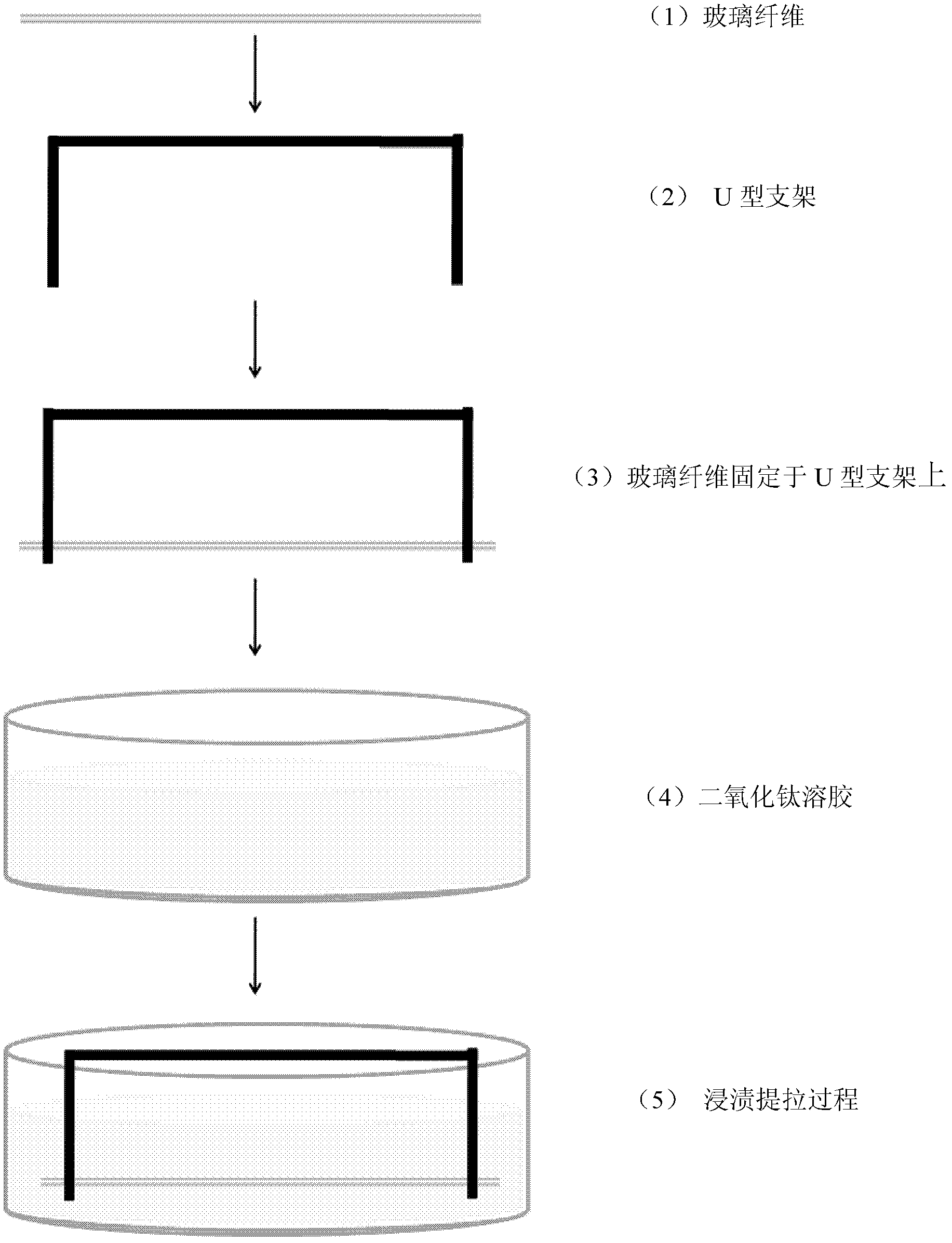

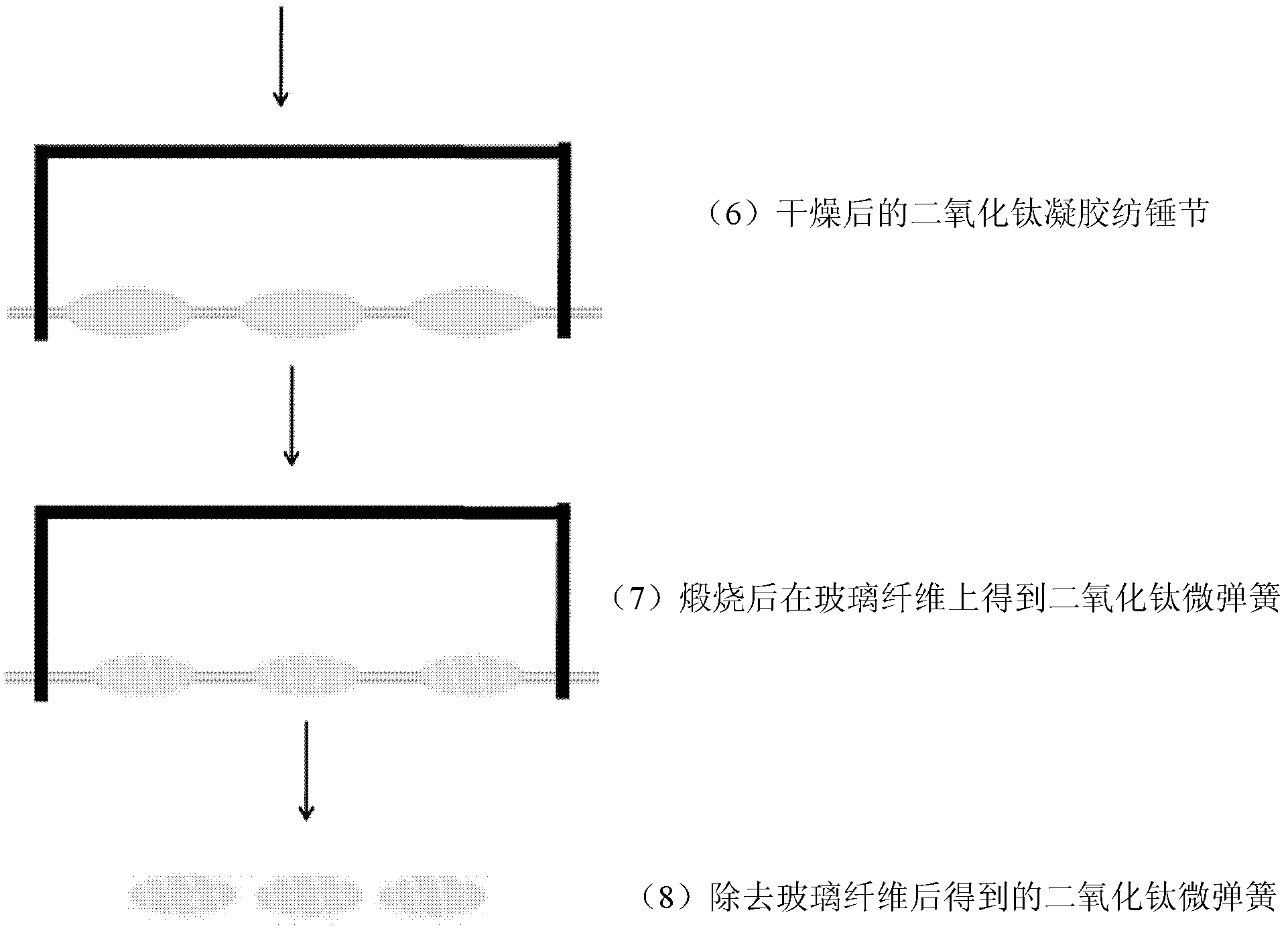

[0028] See figure 1 The fabrication process of the titania microspring is shown.

[0029] (1) Clean the carbon fibers with a diameter of 5 microns with pure water, acetone, and ethanol in sequence, and blow them dry with nitrogen; then fix the cleaned carbon fibers on a base with a length of 5 cm and a height of 2 cm, on a U-shaped bracket made of stainless steel alloy;

[0030] (2) Dissolve 1 gram of P123 (molecular weight: 5800) in 10 mL of absolute ethanol, stir at room temperature to completely dissolve P123 to obtain a P123 ethanol solution, adjust the pH value of the P123 solution to 2.6 with 1M hydrochloric acid, and then add 6.2 grams of Tetrabutyl titanate was stirred for 30 minutes to form a uniform and stable titanium dioxide sol with a quality of 18.4 grams;

[0031] (3) The U-shaped support fixed with carbon fiber in step (1) is immersed in the titanium dioxide sol obtained in step (2), and the U-shaped support fixed with carbon fiber is pulled out from the tit...

Embodiment 2

[0034] (1) Clean the carbon fibers with a diameter of 5 microns with pure water, acetone, and ethanol in sequence, and blow them dry with nitrogen; then fix the cleaned carbon fibers on a base with a length of 5 cm and a height of 2 cm, on a U-shaped bracket made of stainless steel alloy;

[0035] (2) Dissolve 1 gram of P123 (molecular weight of 5800) in 10 mL of isopropanol, stir at room temperature to completely dissolve P123 to obtain a P123 solution, adjust the pH of the P123 solution to 2.6 with 1M hydrochloric acid, and then add 5.1 grams of isopropanol Titanium propoxide was stirred for 30 minutes to form a uniform and stable titania sol, and its quality was 17.3 grams;

[0036] (3) The U-shaped support fixed with carbon fiber in step (1) is immersed in the titanium dioxide sol obtained in step (2), and the U-shaped support fixed with carbon fiber is pulled out from the titanium dioxide sol by pulling method, and dried for 12 After ~24 hours, a titanium dioxide gel spi...

Embodiment 3

[0039] (1) Clean the glass fibers with a diameter of 5 microns with pure water, acetone and ethanol in turn, and dry them with nitrogen; then fix the cleaned glass fibers on a base with a length of 5 cm and a height of 2 cm, on a U-shaped bracket made of stainless steel alloy;

[0040] (2) Dissolve 1 gram of P123 (molecular weight: 5800) in 10 mL of absolute ethanol, stir at room temperature to completely dissolve P123 to obtain a P123 ethanol solution, adjust the pH value of the P123 solution to 2.6 with 1M hydrochloric acid, and then add 6.2 grams of Tetrabutyl titanate was stirred for 30 minutes to form a uniform and stable titanium dioxide sol with a quality of 18.4 grams;

[0041] (3) Immerse the U-shaped bracket fixed with glass fiber in step (1) into the titanium dioxide sol obtained in step (2), and pull the U-shaped bracket fixed with glass fiber out of the titanium dioxide sol by pulling method, Dry for 12 to 24 hours, and prepare a titanium dioxide gel spindle with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com