Method for preparing mesh-shaped bionic bone porous stent material

A technology of porous scaffold and bionic bone, which is applied in the field of biomedical materials and tissue engineering regenerative medicine, can solve problems such as unsatisfactory practical application effects, excessively large pore structure, and application research limitations, and achieve significant social and economic benefits. Preparation Simple process and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of Biomimetic 45S5 Bioactive Glass Scaffold

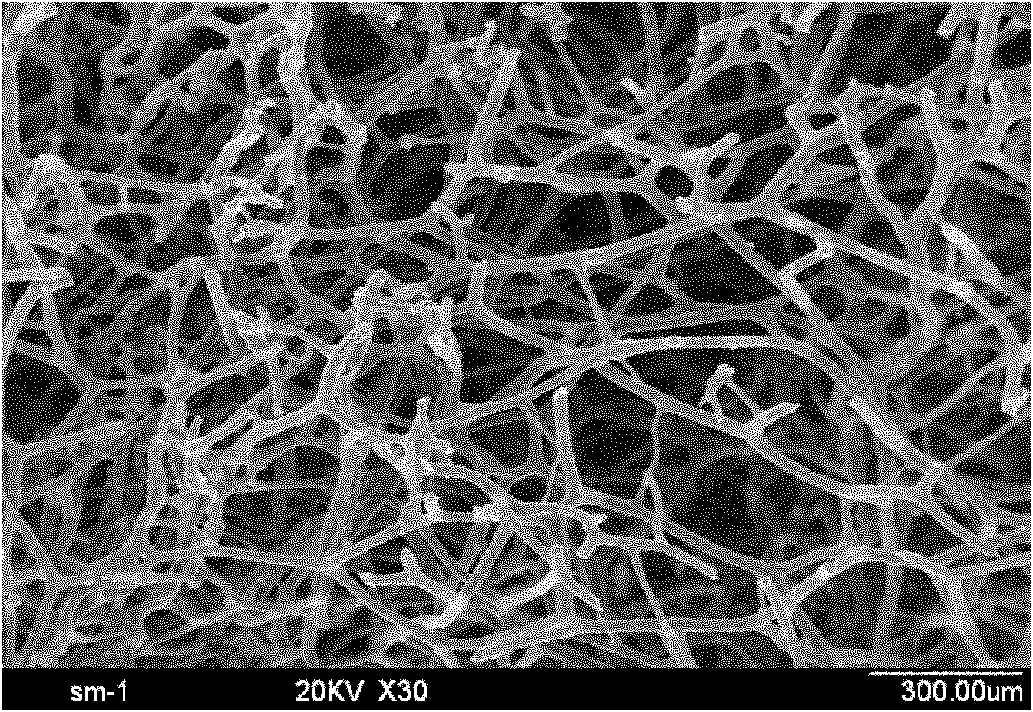

[0029] 1) Template treatment: first soak the natural sponge template in 0.5mol / L acetic acid aqueous solution for 24 hours, and stir slightly during the period. After soaking, take out the natural sponge template and rinse it with distilled water for 3 times; then, rinse the natural sponge template with distilled water Immerse the template in 0.5mol / L sodium hydroxide aqueous solution, keep it under stirring for 24 hours, wash the lye with distilled water after taking it out; finally, dry it under vacuum at 45°C; see the treated natural sponge template figure 1 ,Depend on figure 1 It can be seen that the natural sponge has a typical mesh-like pore structure, the pore size is mainly concentrated in the range of 100-300 μm, the average diameter of the porous skeleton is 20 μm, the skeleton is connected in a trident form, and the porosity is high.

[0030] 2) Preparation of 45S5 sol: firstly mix absolute...

Embodiment 2

[0034] Example 2: Preparation of Biomimetic Hydroxyapatite Scaffold

[0035] 1) Template treatment: first soak the natural sponge template in 2mol / L acetic acid aqueous solution for 12 hours, stir slightly during the period, take out the natural sponge template and rinse it with distilled water for 5 times after soaking; then, rinse the natural sponge template with distilled water Immerse in 2mol / L sodium hydroxide aqueous solution, keep it under stirring for 36 hours, take it out and wash the lye with distilled water; finally, dry it under vacuum at 60°C;

[0036] 2) Preparation of hydroxyapatite water-based slurry: adding nano-hydroxyapatite powder in batches to distilled water containing 5% by mass of binder polyvinyl alcohol and 1% of dispersant ammonium polyacrylate, and dissolving Adjust the pH value of the water-based slurry to 10, and then undergo ball milling at 400 rpm for 8 hours to make a hydroxyapatite water-based slurry with a solid content of 55 wt%.

[0037] 3...

Embodiment 3

[0040] Example 3: Preparation of biomimetic β-tricalcium phosphate scaffold

[0041] 1) Template treatment: first soak the natural sponge template in 1mol / L acetic acid aqueous solution for 36 hours, stir slightly during the period, take out the natural sponge template and rinse it with distilled water for 3 times after soaking; then, rinse the natural sponge template with distilled water Immerse in 1.5mol / L sodium hydroxide aqueous solution, keep it under stirring for 24 hours, take it out and wash the lye with distilled water; finally, vacuum dry at 80°C;

[0042] 2) Preparation of tricalcium phosphate sol: firstly mix absolute ethanol and water at a volume ratio of 3:7 and adjust the pH value of the mixed solution to 1 with nitric acid to obtain ethanol-water solution, then use triethyl phosphate and calcium nitrate as raw materials , measure the raw materials according to the chemical composition ratio of tricalcium phosphate, add the measured raw materials into the ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com