Fracture controllable natural gas pipeline and ductile fracture control method thereof

A technology of ductile fracture and control method, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of high cost and poor economy, and achieve control of production cost, good economy and safety, and saving. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

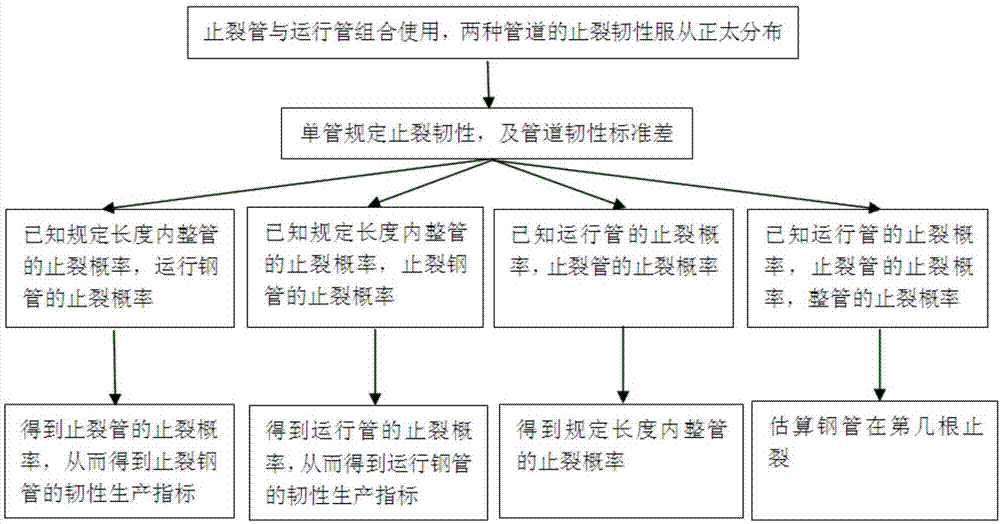

Method used

Image

Examples

example 1

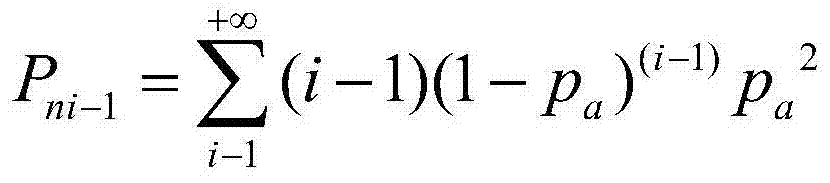

[0041] Example 1: US DOT49CFR Part 192 stipulates that cracks should be stopped within 5-8 steel pipes, and the corresponding crack stop probability should be above 90% and 99% respectively. According to the battle hyperbolic method, the specified crack arrest toughness of X90 single tube is 305J. If the probability of crack arrest within the length of 8 steel pipes reaches 99%, that is, i=8, P=0.99. Let P c = 0.001, the crack arrest probability of a single running steel pipe is 50%, then the crack arrest probability of the crack arrest pipe can be calculated as p b =0.6914, that is, the probability that the crack arrest pipe toughness is higher than the standard crack arrest toughness of 305J is 69.14%. At the same time, according to the normal distribution law, assuming that the standard deviation is 30J (constrained by the production process), the average toughness of the crack arrester can be calculated as 320J, so as to obtain the toughness index of crack arrester manuf...

example 2

[0042] Example 2: The specified crack arrest toughness of X90 single pipe calculated according to the battle hyperbolic method is 305J. If the probability of crack arrest within the length of 8 steel pipes reaches 99%, that is, i=8, P=0.99. Let P c = 0.001, the crack arrest probability of a single crack arrester pipe is 80%, then the crack arrest probability of the running steel pipe can be calculated as p a =0.4628, that is, the probability that the operating pipe toughness is higher than the standard crack arrest toughness of 305J is 46.28%. At the same time, according to the normal distribution law, assuming that the standard deviation is 30J (constrained by the production process), the average toughness of the running pipe can be calculated as 290J, so as to obtain the toughness index of the running pipe manufacturing. Due to the large number of operating pipes, reducing the toughness requirements of the operating pipes can reduce the cost of steel pipe manufacturing, re...

example 3

[0043] Example 3: The specified crack arrest toughness of X90 single pipe calculated according to the battle hyperbolic method is 305J. Assuming that the crack arrest probability of a single crack arrest pipe is 75%, the probability that the operating pipe toughness is higher than the standard crack arrest toughness of 305J is 45%, P c = 0.001, then the probability of crack arrest within the length of 8 steel pipes is 98.56%. The probability of crack arrest within the specified length can be determined according to the toughness distribution index of the running pipe and crack arrest pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com