Coal mine hard roof directional fracturing control method

A directional fracturing, hard roof technology, applied in blasting and other directions, to achieve the effect of strong controllability, avoiding mine pressure disasters, and ensuring safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

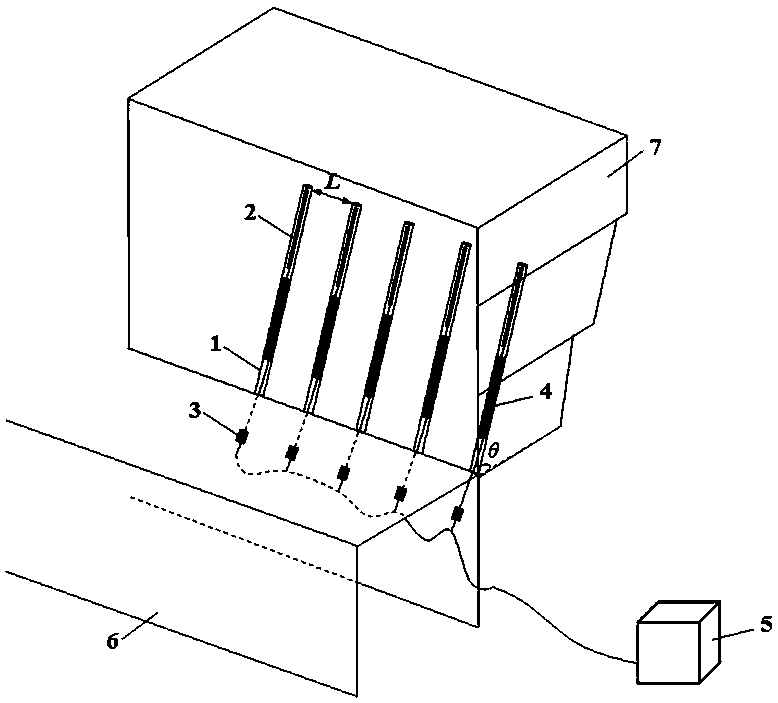

[0014] The method for controlling directional fracturing of a hard roof in a coal mine is realized by the following steps:

[0015] a. Select the uncollapsed roof 7 of the roadway 6 as the area for directional fracturing control, and use drilling rigs at intervals L Carry out drilling, the boreholes 1 are arranged in a straight line along the length direction of the roadway 6, and each borehole 1 is located in the vertical plane of the width direction of the roadway roof and forms an angle θ with the roadway roof; wherein, L is 1-3 meters (such as, Choose 1 meter, 1.5 meters, 2 meters, 2.5 meters, 3 meters), θ is 60~80° (for example, choose 60°, 65°, 70°, 75°, 80°);

[0016] The drilling distance L is related to the charge of the compound perforator. The larger the distance L is, the greater the charge of the compound perforator is. ).

[0017] b. Assemble compound perforator 2;

[0018] c. Each borehole 1 is loaded with a compound perforator 2, and then each borehole 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com