Rotary power exchanger with extended inflow angle structure

A rotary and inflow angle technology, applied in the direction of machines/engines, etc., can solve the problems of increasing friction and impact between sliding parts, reducing the volumetric efficiency of the channel, occupying the space of the channel, etc., so as to reduce the flow loss and have strong operation flexibility , the effect of reducing the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

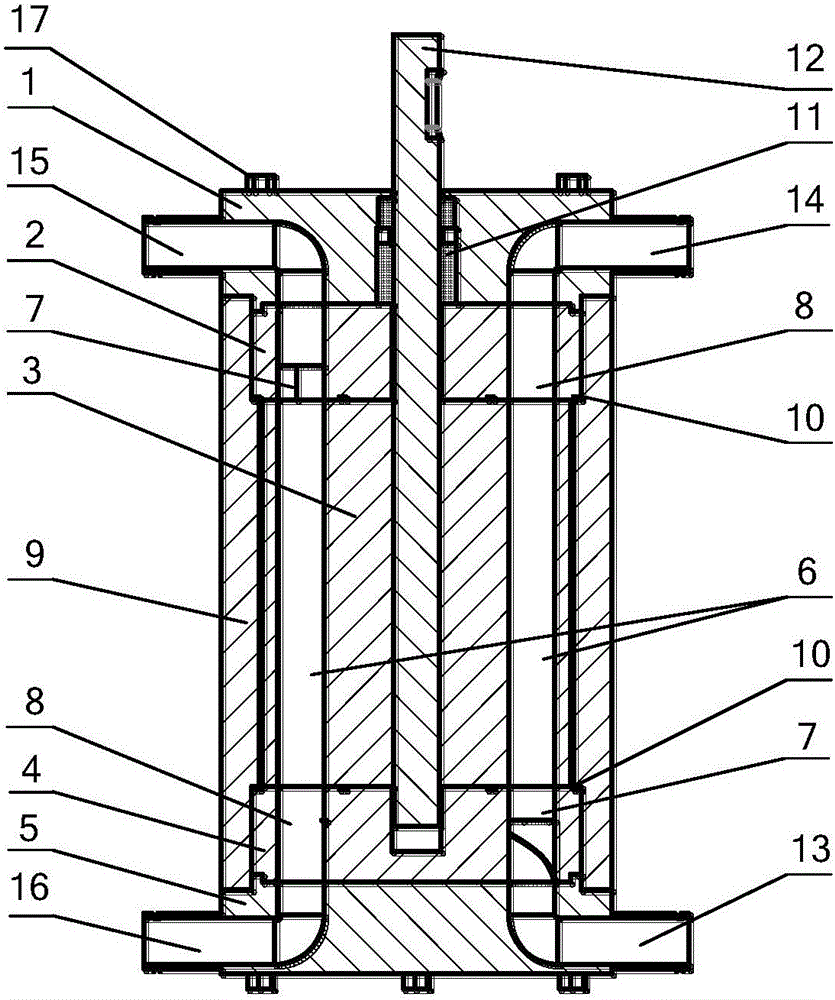

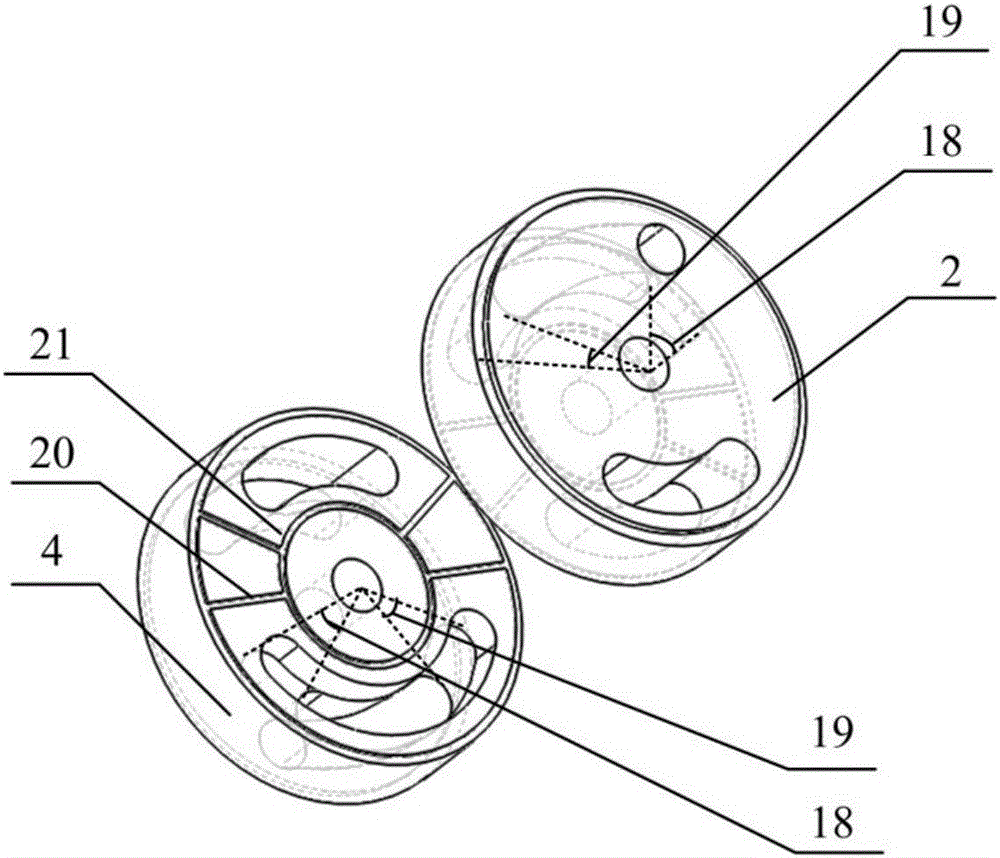

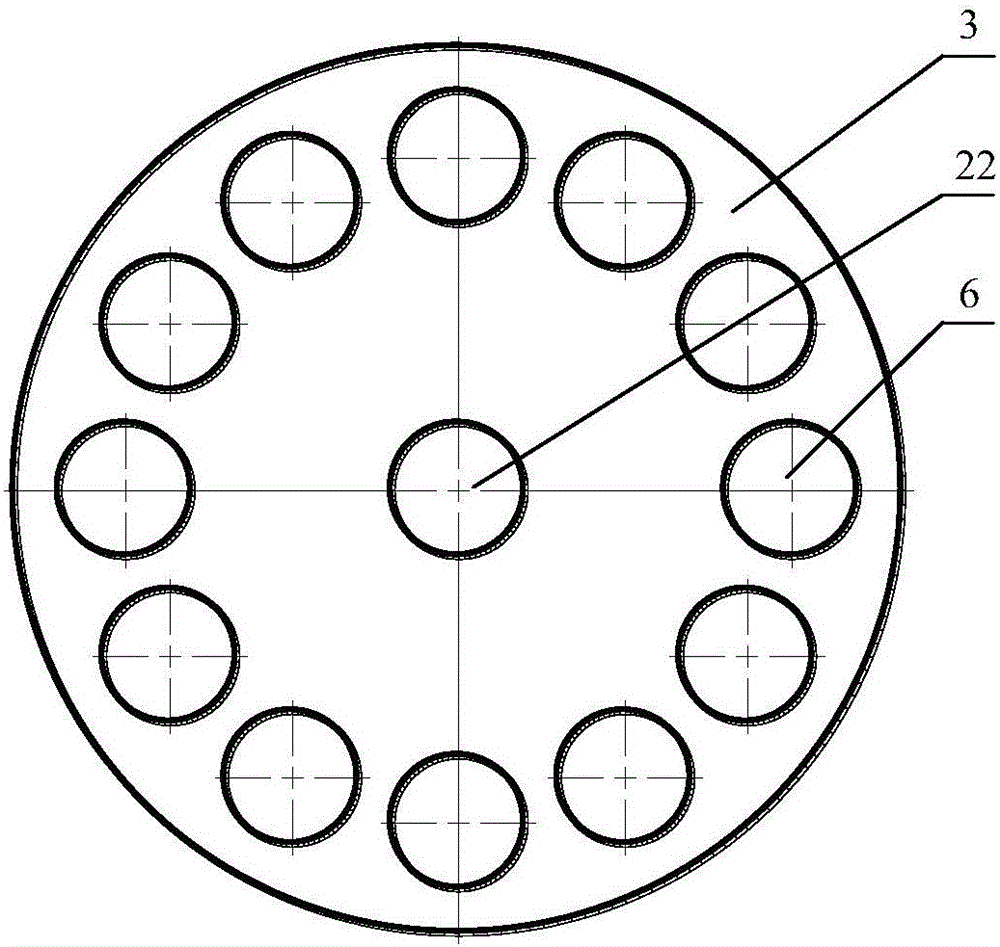

[0035] see figure 1 with Image 6 , the rotary work exchanger structure with extended inlet angle structure of the present invention includes a rotor 3 with a circular rotor hole 6, an upper stator 2 and a lower stator 4 located at the upper and lower ends of the rotor 3, and a sleeve 9 four parts. The upper stator 2 communicates with the low-pressure liquid inlet 15 and the high-pressure liquid outlet 14 , and the lower stator 4 communicates with the high-pressure liquid inlet 13 and the low-pressure liquid outlet 16 . The upper stator 2 and the lower stator 4 are connected with the rotor 3 through the rotor central shaft 12. The rotor central shaft 12 supports the rotor 3 and is connected with an external motor to drive the rotor to rotate. The rotor central shaft 12 is equipped with mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com