Foam concrete slip-casting system and method for mine hole collapse prevention

A foam concrete and grouting system technology, which is applied to drilling equipment and methods, earthwork drilling, mining equipment, etc., can solve the problems of less research on air permeability, achieve improved prevention and control technology, good use effect, and increase drainage efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

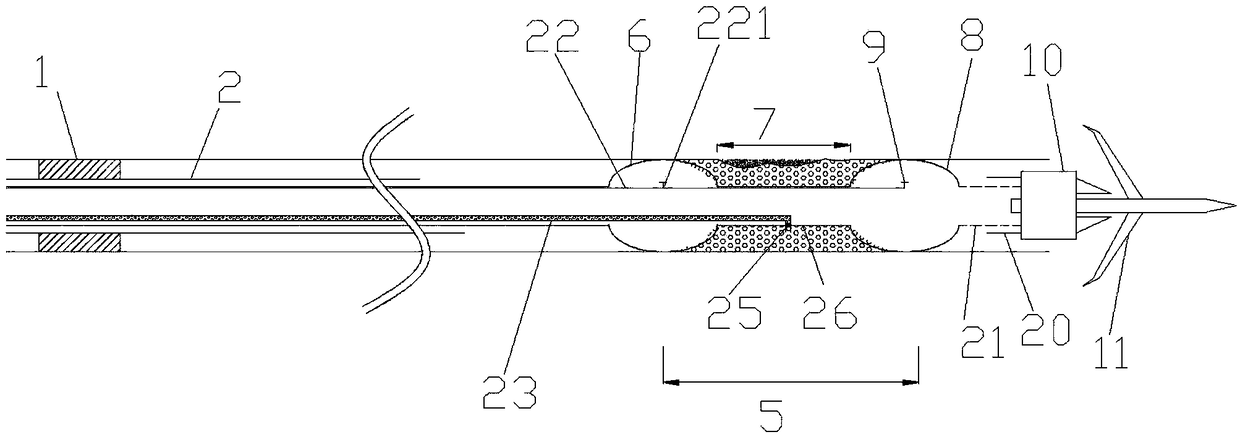

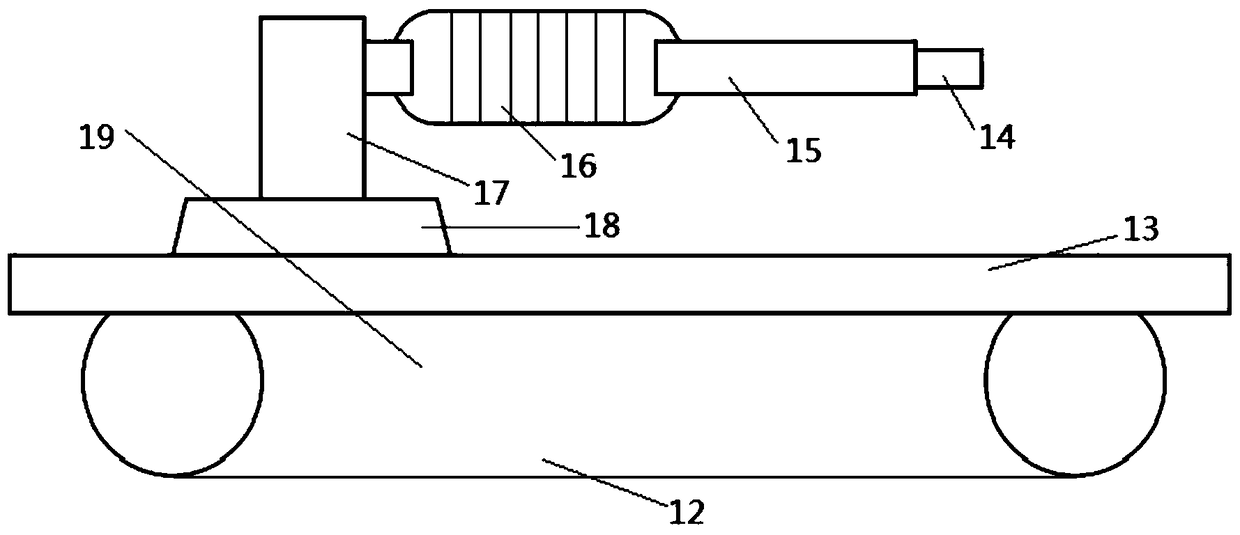

[0031] Such as Figure 1-Figure 3 As shown, a kind of foam concrete grouting system for the prevention and treatment of mine hole collapse in this embodiment includes a crawler hydraulic drilling rig 19 that can adjust the inclination and power. The hydraulic drilling rig 19 includes a fuselage 13, crawlers 12, bearings Table 18, stand 17, motor 16, outer drill pipe 15 and inner drill pipe 14; the system also includes a rod sleeve device 24, an air-inflated or water-injected capsule device, air-inflated or water-injected and its monitoring and feedback device, and injection of the position of the collapsed hole. Grouting device for grouting;

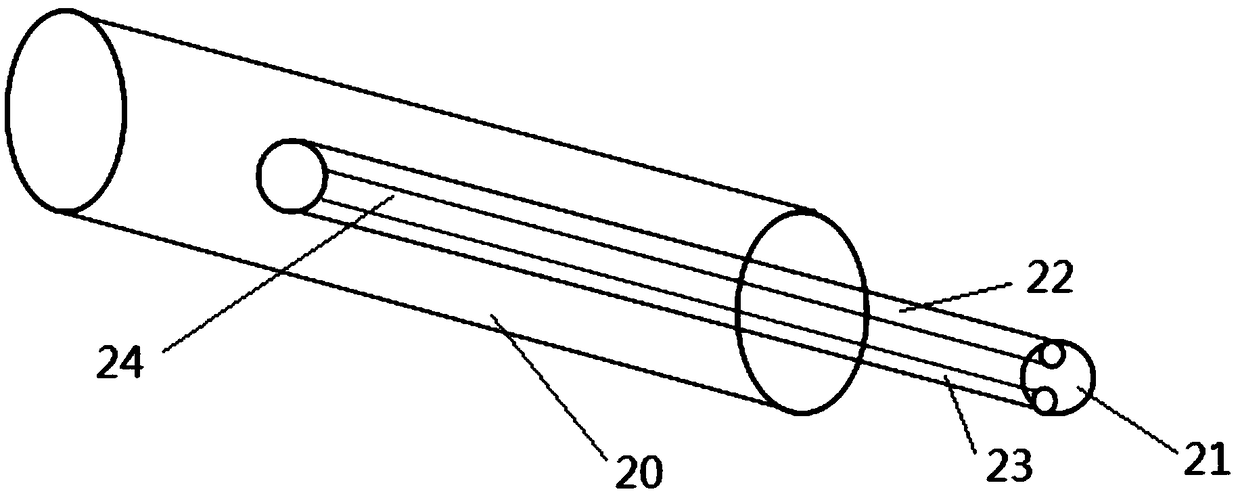

[0032]The rod sleeve device 24 includes an outer rod 20 threadedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com