Enlarged chamber alleviation structure on end part of high-speed railway tunnel

A technology for high-speed railways and tunnels, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of high cost, poor economy, high construction cost, etc., and achieve the goal of reducing pressure gradient, reducing influence, and reducing the peak value of micro-pressure waves Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

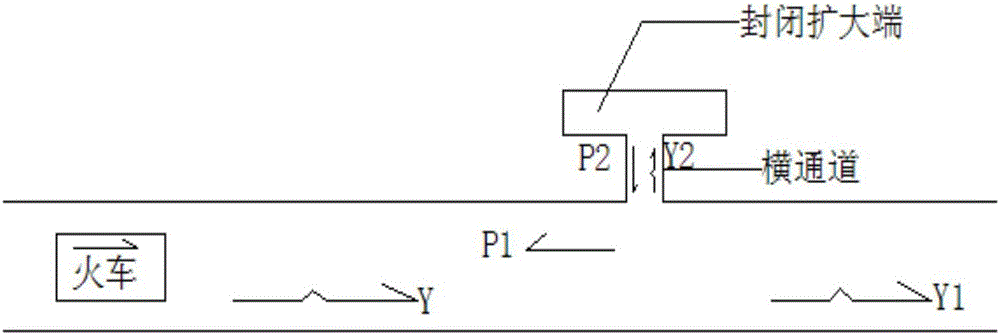

[0020] Such as Figure I As shown, when the high-speed train enters the tunnel, the air in front of the train is compressed, and a compression wave is generated. The compression wave is represented by Y in the figure, and the expansion wave is represented by P. It can be seen that when the compression wave Y generated in front of the train propagates to the chamber, it is divided into three parts, one of which is reflected in the form of expansion wave and propagates toward the tunnel entrance. Figure I P1 in ; the other two parts propagate along the forward and transverse channels of the tunnel respectively in the form of compression waves, as shown by Y1 and Y2 in the figure. When Y2 propagates along the transverse channel to the closed expansion end, part of it is transmitted to the closed expansion end in the form of waves of the same sign, and undergoes repeated complex reflection processes until it disappears; channel, and then generate two waves of the same sign that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com