Low-pressure sealing system applied to sectional form mould core/mould and sealing method thereof

A low-pressure sealing and sealing system technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as poor maintenance, non-monitoring, and difficulty in maintaining air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

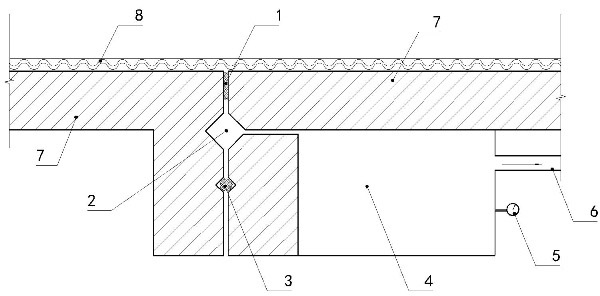

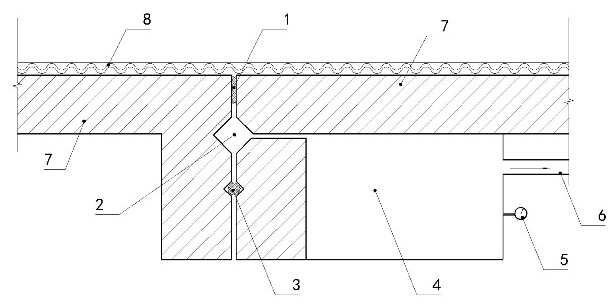

[0026] figure 1 It is a schematic cross-sectional structure diagram of the low-pressure sealing system provided by the present invention.

[0027] Such as figure 1 As shown, the low-pressure sealing system provided by the present invention includes an inner layer sealing system 1 and an outer layer low-pressure sealing system, and the outer layer low-pressure sealing system includes an air guide groove 2, an O-shaped rubber ring 3, a large container 4, a vacuum gauge 5, a pump Air duct 6, valve (not shown in the figure) and air extractor (not shown in the figure).

[0028] The inner sealing system 1 (composed of sealing rubber strips) isolates the working space 8 from the air guide groove 2 of the outer low-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com