Micro-channel parallel flow evaporator

A micro-channel, parallel flow technology, applied in evaporators/condensers, refrigeration components, refrigerators, etc., can solve the problems of increased experimental and simulation analysis workload, many adjustment parameters, complex structure, etc., to improve refrigeration capacity and The effect of uniformity of air temperature distribution, uniform pressure distribution and uniform pressure field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

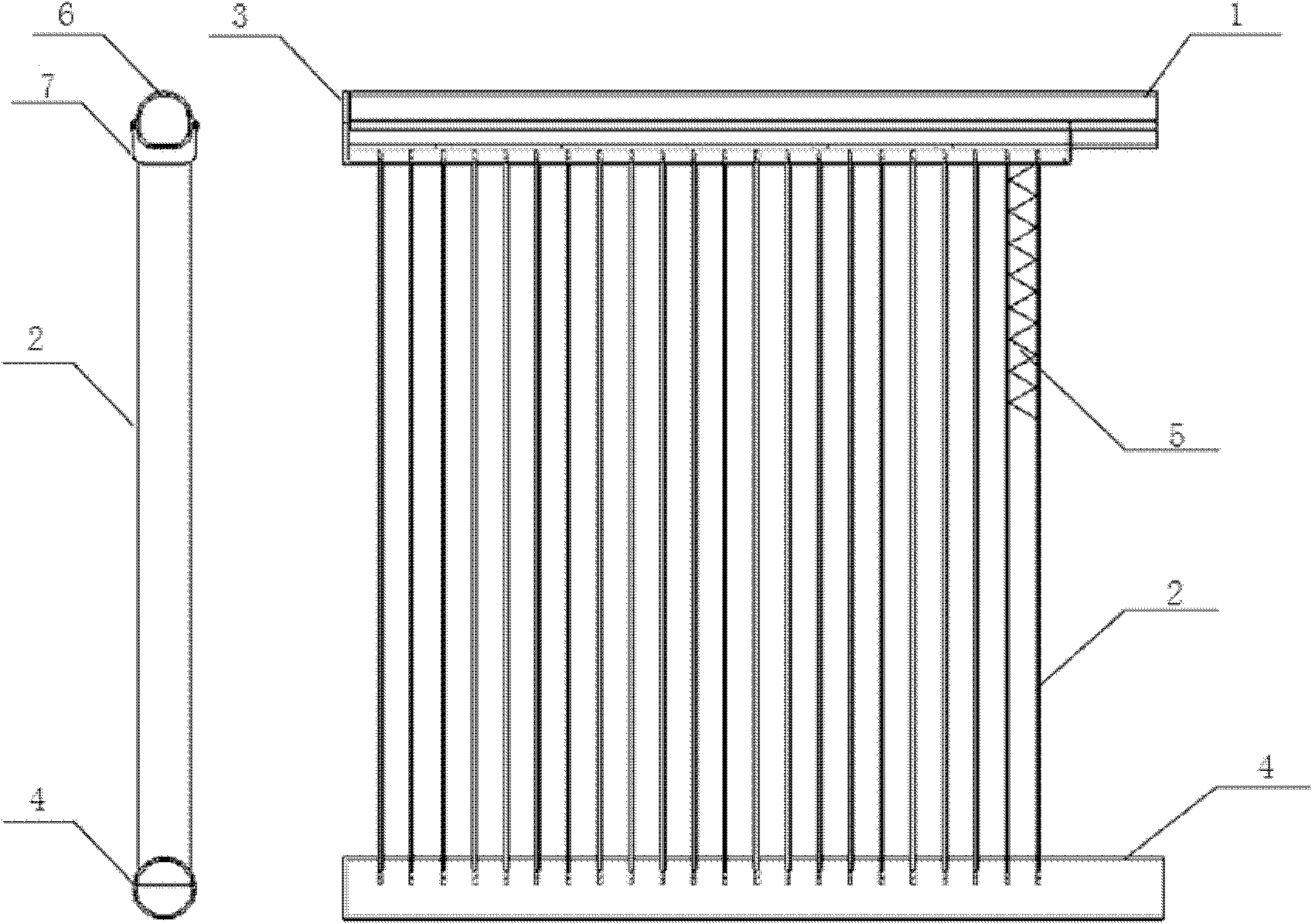

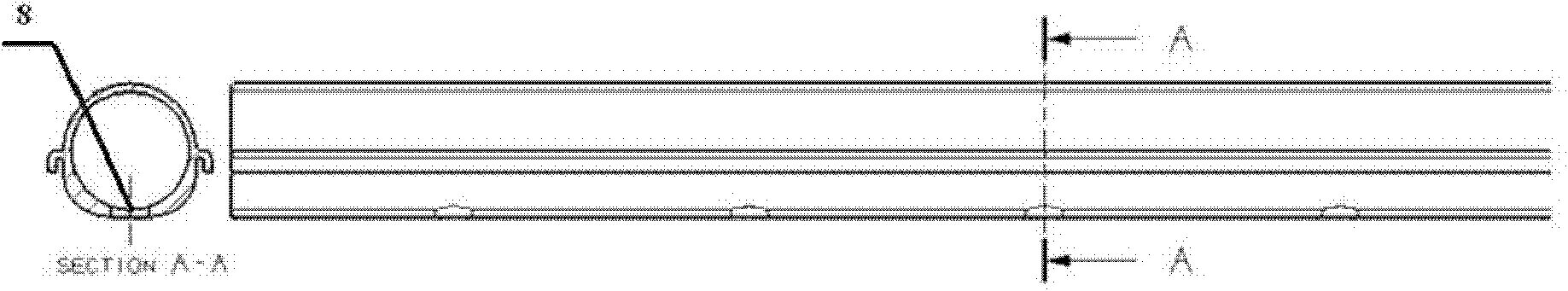

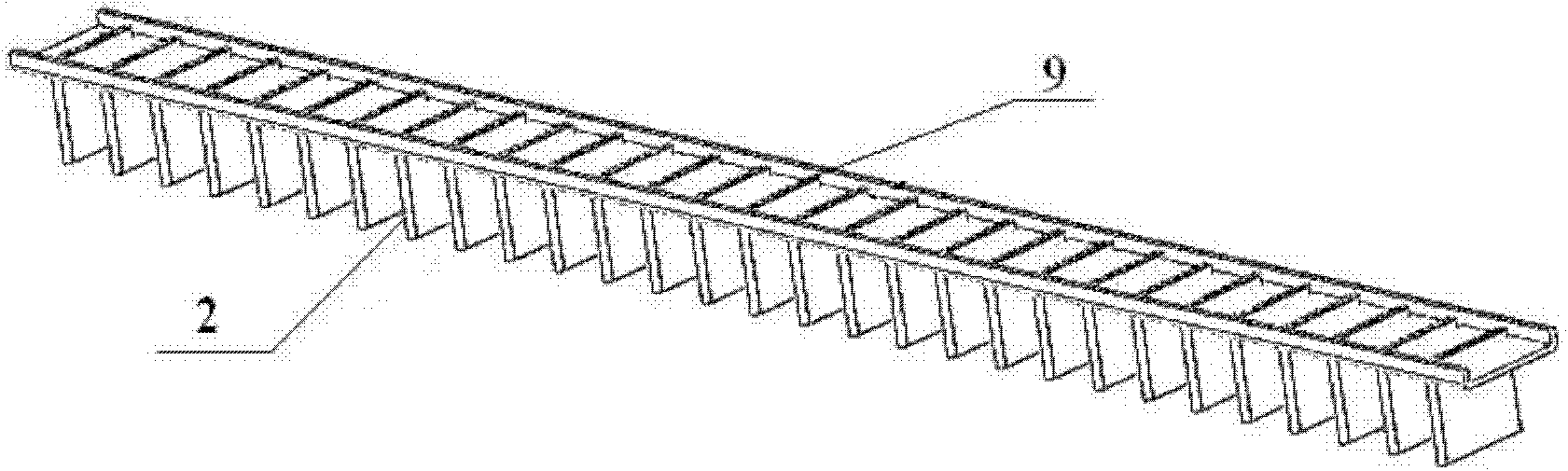

[0025] Such as figure 1 As shown, this embodiment includes: an upper liquid collection pipe assembly 1, several evenly arranged flat pipes 2, two end caps 3 and a lower liquid collection pipe 4, wherein: the two end faces of the upper liquid collection pipe assembly 1 are respectively connected to The two end caps 3 are connected, the top of the upper liquid collecting pipe assembly 1 is connected with a device containing refrigerant, and the two ends of each flat tube 2 are respectively connected with the bottom of the upper liquid collecting pipe assembly 1 and the lower liquid collecting pipe 4 .

[0026] The upper liquid collection pipe assembly 1 includes: a refrigerant distribution pipe 6 and an upper liquid collection pipe main board 7, wherein: the refrigerant distribution pipe 6 is connected to the upper liquid collection pipe main board 7, and the top of the refrigerant distribution pipe 6 is connected to the inner The refrigerant device is connected, and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com