Contact mechanical oil carrying device for sliding bearing

A technology of sliding bearings and mechanical belts, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reducing the reliability of self-lubricating sliding bearings, failing to ensure sufficient lubricating oil supply, and inconvenient overall system design, etc., to achieve Light weight, compact structure, avoid mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

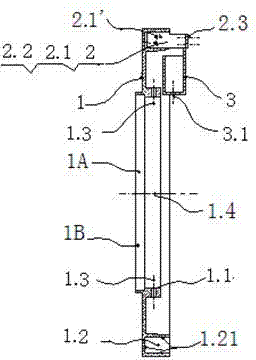

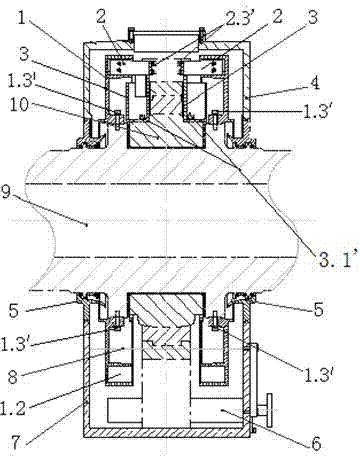

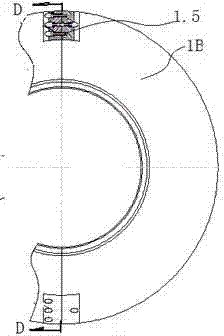

[0036] Such as Figure 1-10 As shown, a contact type sliding bearing mechanical oiling device, which includes an oil pan 1, an oil scraping device 2 and an oil receiving device 3; as figure 1 , 2 , 3, and 4, wherein: the oil pan 1 is an integral annular disc composed of two semi-rings A semi-ring 1A and B semi-ring 1B, and one end face of the annular disc is outside There is an annular groove for carrying oil in the ring, that is, the oil groove 1.2; the inner surface of the oil groove 1.2 is a smooth surface that can slide in contact with the side of the oil scraper 2.2; the oil pan 1 passes through its inner ring hole 1.1 and the belt The oil pan fixing hole 1.3 and the oil pan fixing part 1.3' are fixedly connected with the rotating shaft 9; as figure 2 , 5 , 6, 7, and 8, the oil scraper 2 includes a bracket 2.1; an oil scraper 2.2 is installed at one end of the bracket 2.1, and the other end is a bracket seat 2.3; the side of the oil scraper 2.2 is close to the oil tan...

Embodiment 2

[0038] The present invention is a sliding bearing seat used for a contact sliding bearing mechanical oiling device, comprising a bearing upper seat 4 and a bearing lower seat 7; the bearing upper seat 4, the bearing lower seat 7 and the rotating shaft 9 are matched with a sealing end cover 5; Bearing upper seat 4 is that lubricating oil liquid level 8 can submerge the oil pool with oil groove 1.2, and cooler 6 is installed in this oil pool. A contact type sliding bearing mechanical oiling device can be respectively installed at the two ends of the sliding bearing 10 in the described sliding bearing seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com