Crossbeam structure of semitrailer and welding process thereof

A welding process and semi-trailer technology, applied in the substructure, welding equipment, manufacturing tools, etc., can solve problems such as welding errors, heavy girders, and component offsets, and achieve the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

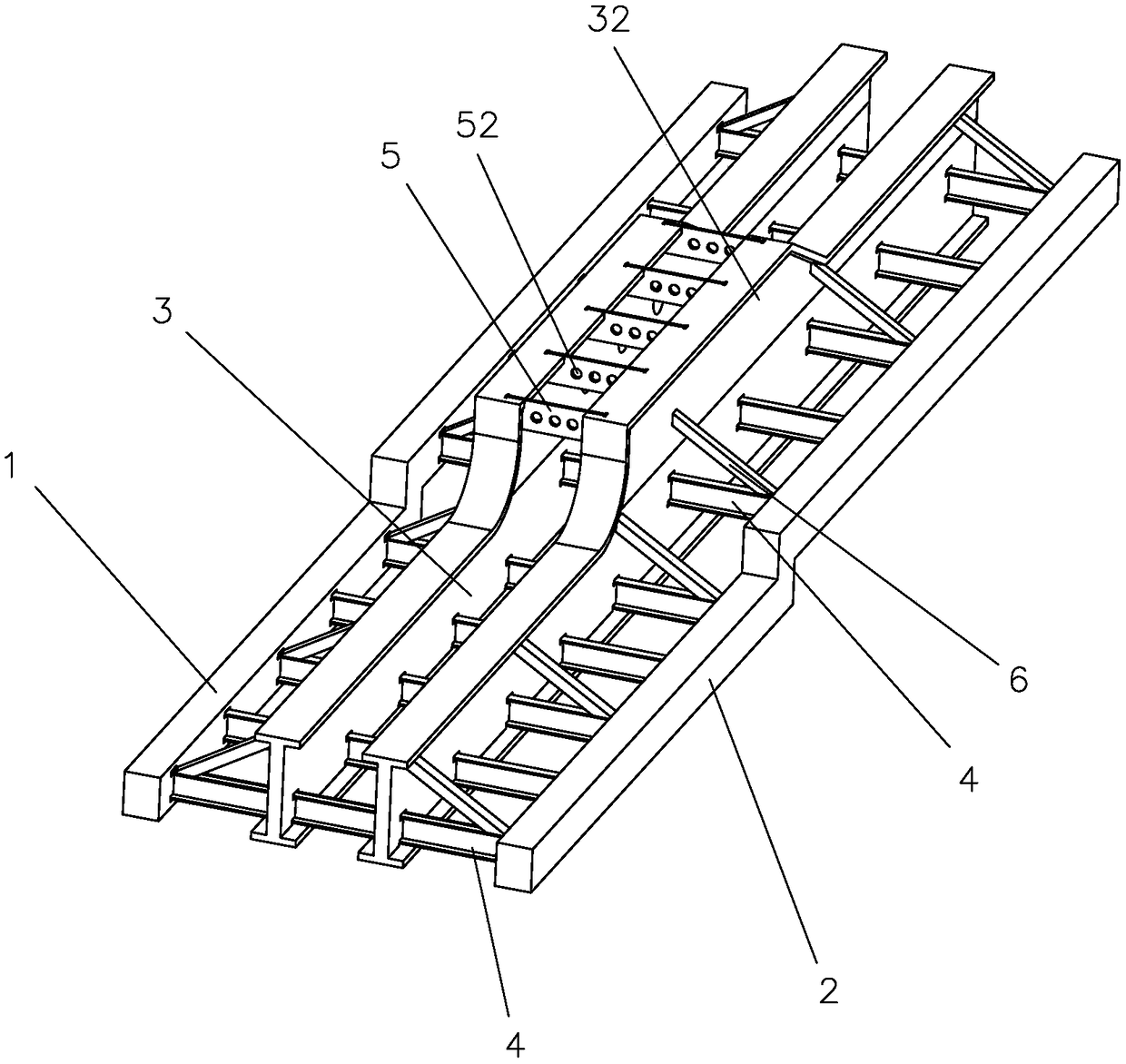

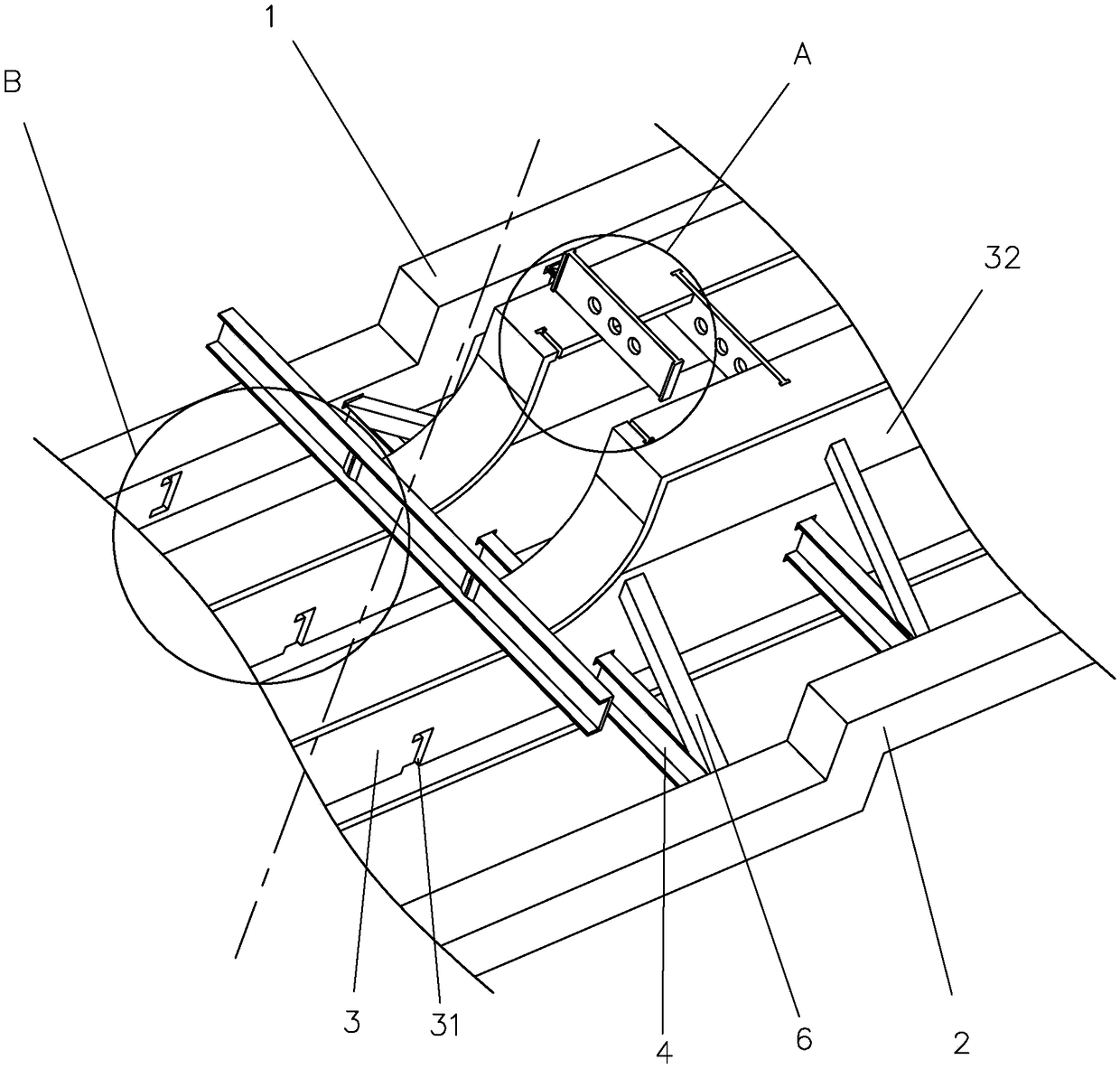

[0038] Embodiment 1: a kind of semi-trailer beam structure, such as figure 1 , 2 As shown, it includes a left wing plate 1 and a right wing plate 2, two webs 3 are arranged between the left wing plate 1 and the right wing plate 2, and a plurality of connecting plates with bow-shaped sections are also arranged between the left wing plate 1 and the right wing plate 2 4. In addition, each web 3 is provided with a plurality of arcuate insertion holes 31 , and the two ends of each connecting plate 4 respectively pass through each insertion hole 31 and are fixed on the side walls of the left wing 1 and the right wing 2 .

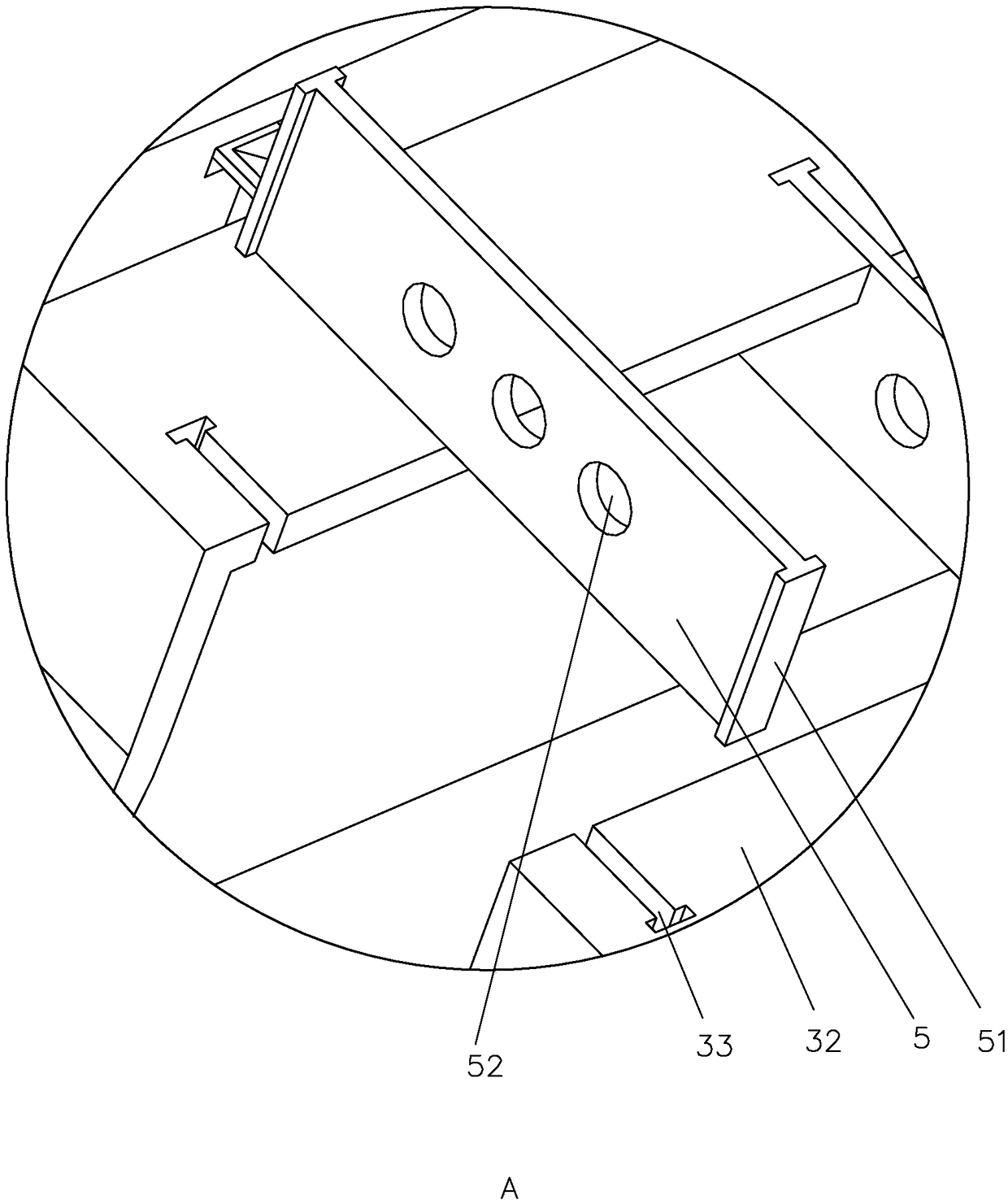

[0039] like figure 2 , 3 As shown, an extension plate 32 is integrally connected to the middle of each web 3, a plurality of T-shaped slots 33 are respectively provided on the opposite side of each extension plate, and a positioning plate 5 is arranged between each extension plate 32 for positioning The two ends of the plate 5 are respectively fixedly connecte...

Embodiment 2

[0043] Embodiment 2: a kind of semi-trailer girder welding process, its welding process comprises the following steps:

[0044] S1, align and place the two ends of the two webs 3 and keep them parallel, then insert the two ends of each positioning plate 5 into the T-shaped slot 33 of each web 3, and at the same time make the clamping plate 51 clamp into the T-shaped slot 33;

[0045] S2, spot welding the two ends of each positioning plate 5 respectively;

[0046] After the web 3 is aligned and placed and the positioning plate 5 is inserted into each T slot, at this moment the clamping plate 51 will be stuck in the T-shaped slot 33, and the two ends of the positioning plate 5 are spot welded and fixed on the T slot. On the web 3, the two webs 3 will be relatively fixed, so as to prevent the web 3 from moving when installing other parts on the web 3 later, so that other parts cannot be accurately installed on the designated position.

[0047] S3, each connecting plate 4 is respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com