A method for fully laminating a display module

A technology for displaying modules and manufacturing methods, which is applied in the direction of material gluing, devices for coating liquid on the surface, identification devices, etc., and can solve problems such as easy displacement of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

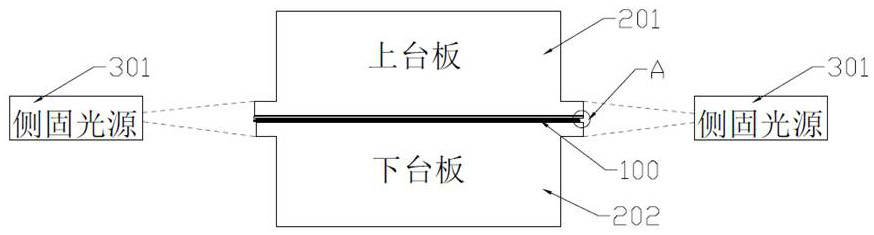

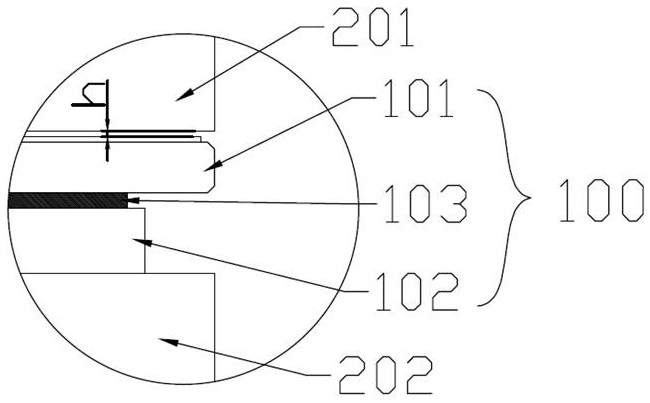

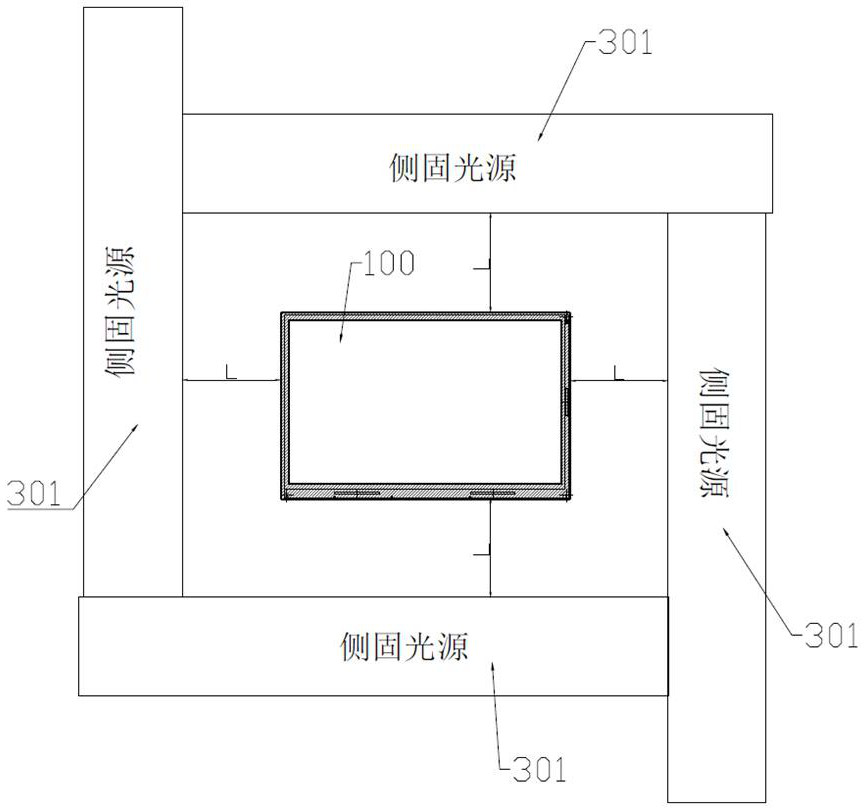

[0030] Figure 1~Figure 3 It is the accompanying drawing of the embodiment of the present invention. The invention provides a method for fully laminating a display module. The display module 100 includes a first substrate 101 and a second substrate 102 .

[0031] In this embodiment, the first substrate 101 is a touch screen, and the second substrate 102 is a display screen.

[0032] The full lamination manufacturing method of the display module 100 includes the following steps:

[0033] (1). Coating: using screen printing coating technology, using an automatic glue coating device to coat the first substrate 101 with optical glue to form an optical glue layer 103;

[0034] (2). Alignment and bonding: first use the alignment adjustment system to align the first substrate 101 and the second substrate 102 on the horizontal plane; then attach the first substrate 101 and the second substrate 102, and pass Move the alignment adjustment system to control the thickness of the dis...

Embodiment 2

[0049] Different from Embodiment 1, in this embodiment, the first substrate is a screen cover, and the second substrate is a display screen.

Embodiment 3

[0051] Different from Embodiment 1, in this embodiment, the first substrate is a display screen, and the second substrate is a screen cover or a touch screen.

[0052] Compared with the prior art, the beneficial effects of the present invention are as follows:

[0053] After the first substrate and the second substrate are aligned and bonded, the display module is directly exposed and cured at the bonding station, and the display module does not need to be moved, which simplifies the process steps. Moreover, the problem that the glue easily flows during the process of moving the display module to the next station is avoided. In addition, by exposing and curing the four sides of the display module at the same time, the four sides of the optical adhesive layer will be cured first to form a glue wall. The relative position remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com