Quench bath composition and application thereof

A technology of composition and quenching liquid, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of limiting the use range of quenching liquid, deformation and cracking of workpieces made of high hardenability materials, and large cooling rate, so as to reduce quenching deformation and the effect of the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0022] Add correctly measured water into the blending kettle, sequentially add the required amount of polyether, polyvinylpyrrolidone, antirust agent, defoamer, triethanolamine, and stir at room temperature for 2 to 10 hours to obtain a colorless transparent liquid. Before use, the obtained quenching liquid composition was diluted with water (10% by weight) for quenching.

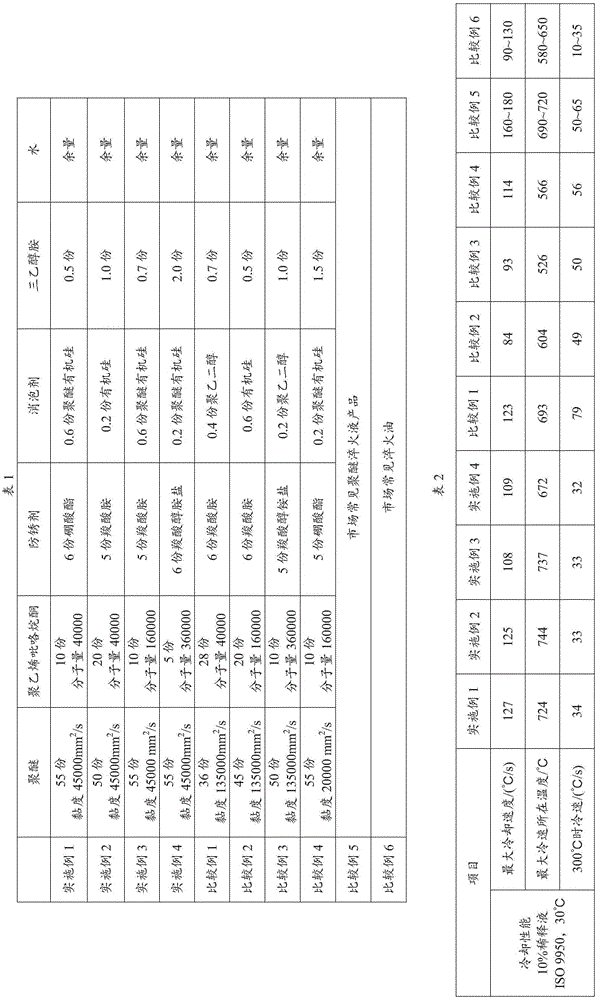

[0023] The components and contents of the quenching liquid composition are shown in Table 1, and the corresponding performance index results are shown in Table 2. in FIG. 1,

[0024] Polyether: Hersbit Chemical Co., Ltd.;

[0025] Polyvinylpyrrolidone: Aladdin's reagent;

[0026] Borate ester: Shanghai Hongze Chemical Co., Ltd.;

[0027] Carboxylic acid amine: Shanghai Hongze Chemical Co., Ltd.;

[0028] Carboxylic acid alcohol ammonium salt: Shanghai Hongze Chemical Co., Ltd.;

[0029] Polyether silicone: Shanghai Yucheng Chemical Co., Ltd.;

[0030] Silicone: Shanghai Yucheng Chemical Co., Ltd.;

...

Embodiment 5

[0039] The quenching liquid composition of [Example 1-4] is used to replace a certain quenching oil quenching process in the market at 20-40°C. In the process of use in a heat treatment plant, there is no deformation or cracking of the workpiece after quenching. The surface quality of the workpiece is good, and the hardness, hardened layer depth, metallographic structure and other indicators meet the requirements. Safety and environmental requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com