Heating body with heating mesh inlaid on surface porous ceramic and preparation method thereof

A ceramic heating element and porous ceramic technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of easy deformation and cracking of heating sheets, uneven temperature distribution, short service life, etc., achieve good user experience, and solve slow heating speed , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

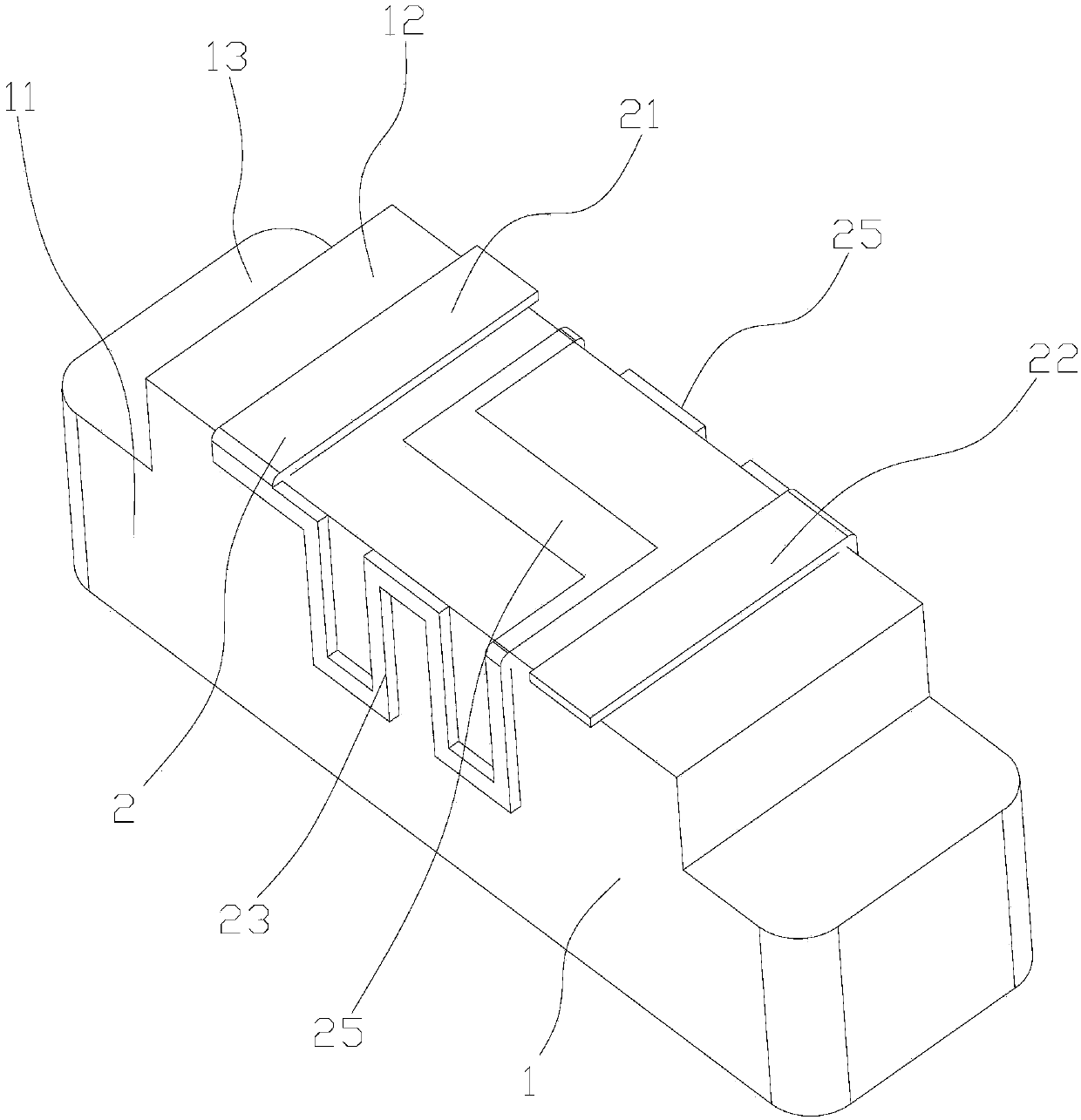

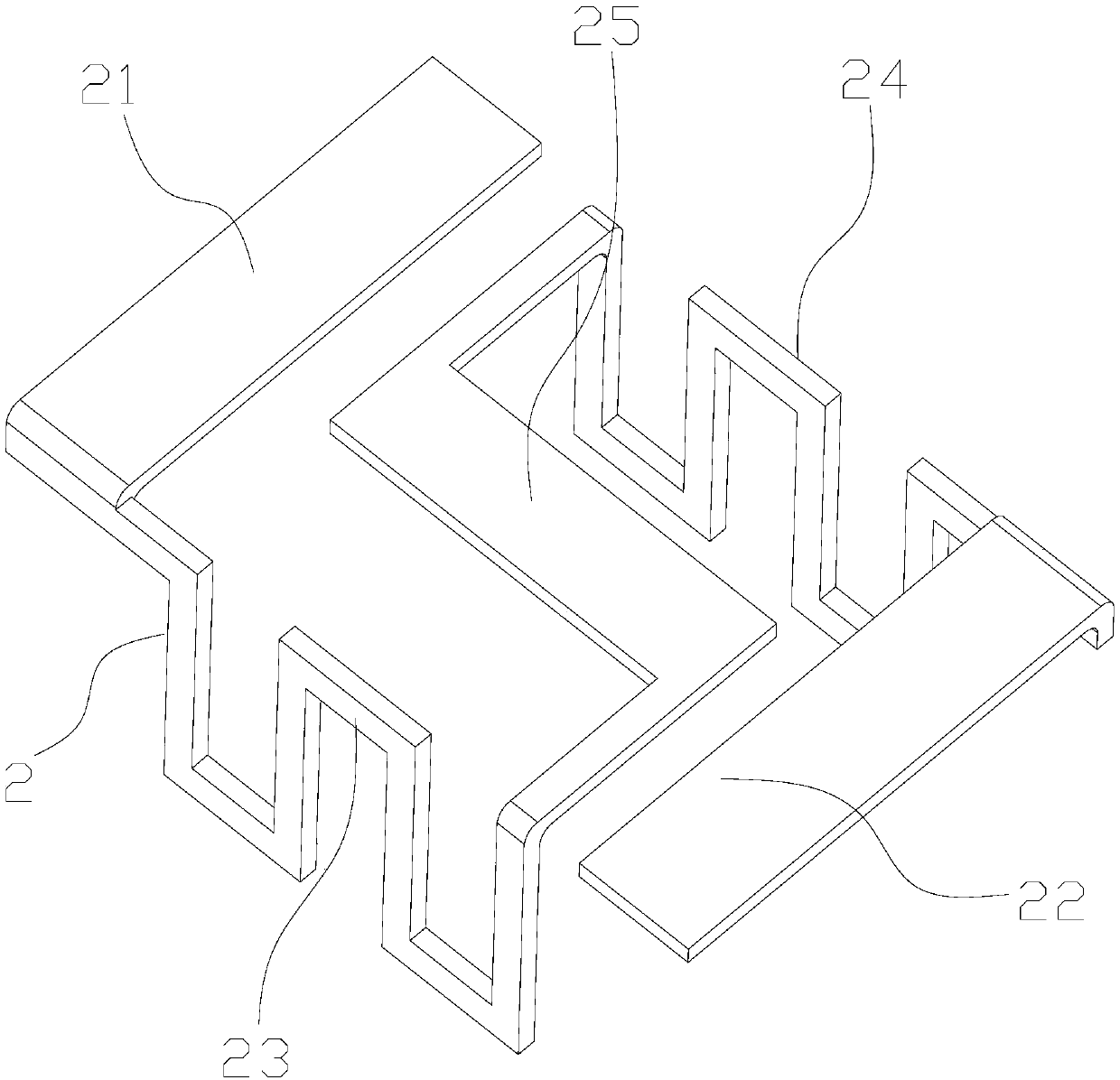

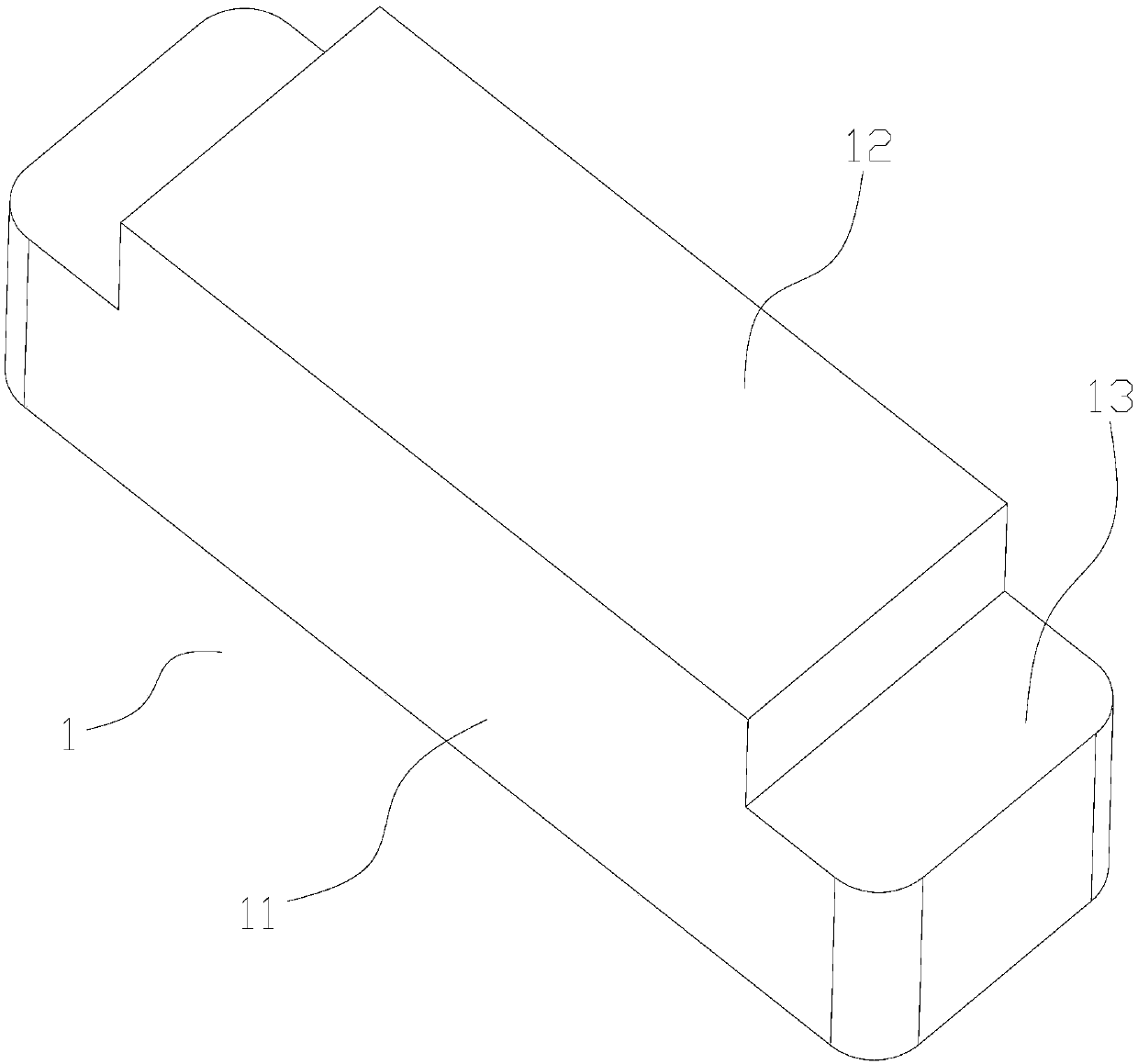

[0040] Embodiment 1, specifically refer to Figure 1-5 , a heating element with a porous ceramic surface embedded with a heating mesh, comprising a ceramic base 1 and a heating mesh 2 embedded in the ceramic base 1, the ceramic base 1 is a ceramic body with a porous structure inside, and the heating mesh The sheet 2 is embedded on the surface of the ceramic base 1. The heating mesh 2 has at least two ends and a wall surface exposed on the surface of the ceramic base 1. The ceramic base 1 and the heating mesh 2 together form a heating body.

[0041]Preferably, the ceramic base 1 includes a base body 11 and a base protrusion 12 extending upward from the base body 11, and the heating mesh 2 includes a first end connection piece 21, a second end connection piece 22, a second end connection piece One side heating sheet 23, the second side heating sheet 24 and the middle connection heating sheet 25;

[0042] The first side heating sheet 23 and the second side heating sheet 24 are b...

Embodiment 2

[0046] Embodiment 2: specific reference Image 6

[0047] This embodiment is basically the same as Embodiment 1, and its difference is that: the upper part of the cross-section of the ceramic base 1 is a trapezoidal structure, the side wall of the upper part of the ceramic base 1 is an inclined wall, and the heating mesh 2 is embedded in the ceramic base 1. On vertical side walls, inclined side walls and horizontal upper walls.

Embodiment 3

[0048] Embodiment 3: specific reference Figure 7

[0049] This embodiment is basically the same as Embodiment 1, except that the upper part of the cross-section of the ceramic base 1 is arc-shaped, and the two sides of the upper part of the ceramic base 1 are inclined walls, and there is an arc between the two inclined walls. The shaped upper wall serves as a transitional surface, and the heating mesh 2 is embedded on the vertical wall, the inclined wall and the arc-shaped transitional upper wall of the ceramic base 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com