MEMS gas sensor and manufacturing method thereof

A technology of gas sensor and manufacturing method, which is applied in the direction of electric solid-state devices, semiconductor devices, instruments, etc., can solve the problems of affecting the heat insulation effect, deformation and rupture of devices, and rapid heat loss, etc., so as to solve heat loss, improve shock resistance and stability performance, enhance the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

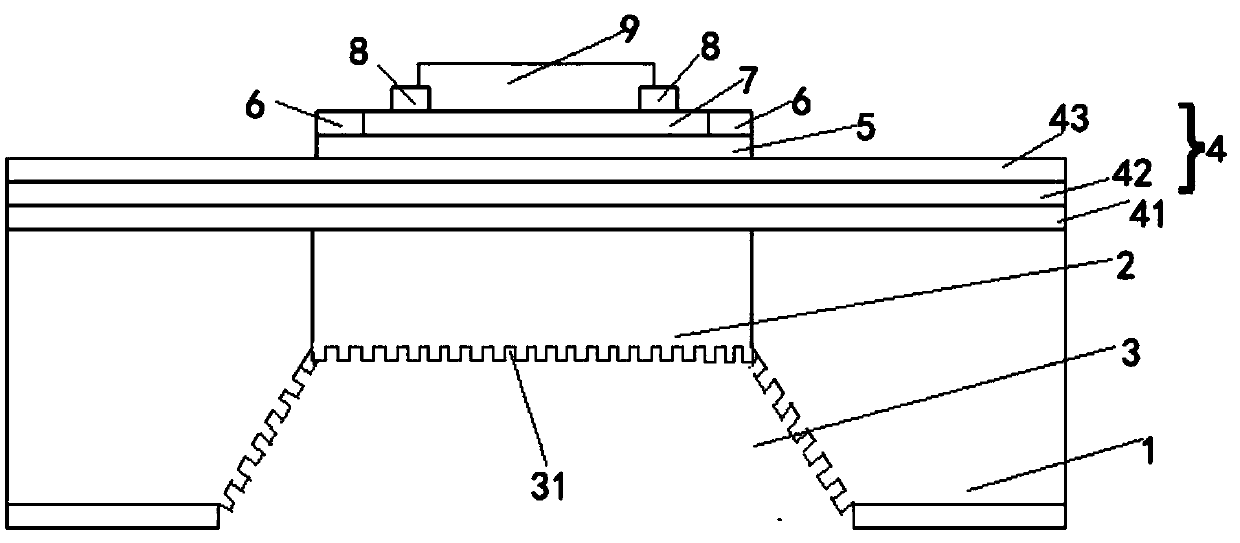

[0031] Example 1: figure 1 It is a structural schematic diagram of the MEMS gas sensor of the present invention, and it can be clearly seen from the figure that the MEMS gas sensor of the present invention includes: a single crystal silicon substrate 1; a porous silicon layer 2, which is formed on the surface of the single crystal silicon substrate 1 The upper surface has a thickness downward, and a silicon dioxide film is formed on the upper surface and the surface of the hole wall of the porous silicon layer 2; the heat insulating groove 3 is formed on the lower surface of the single crystal silicon substrate 1, and the heat insulating The groove 3 is an undercut groove, the bottom surface of the heat insulating groove 3 is located directly below the porous silicon layer 2, and the wall and bottom surface of the heat insulating groove 3 are provided with one or more groove groups, wherein each groove group includes A plurality of trenches 31 arranged in parallel; the lower i...

Embodiment 2

[0050] Example 2: figure 1 It is a structural schematic diagram of the MEMS gas sensor of the present invention, and it can be clearly seen from the figure that the MEMS gas sensor of the present invention includes: a single crystal silicon substrate 1; a porous silicon layer 2, which is formed on the surface of the single crystal silicon substrate 1 The upper surface has a thickness downward, and a silicon dioxide film is formed on the upper surface and the surface of the hole wall of the porous silicon layer 2; the heat insulating groove 3 is formed on the lower surface of the single crystal silicon substrate 1, and the heat insulating The groove 3 is an undercut groove, the bottom surface of the heat insulating groove 3 is located directly below the porous silicon layer 2, and the wall and bottom surface of the heat insulating groove 3 are provided with one or more groove groups, wherein each groove group includes A plurality of trenches 31 arranged in parallel; the lower i...

Embodiment 3

[0069] Example 3: figure 1 It is a structural schematic diagram of the MEMS gas sensor of the present invention, and it can be clearly seen from the figure that the MEMS gas sensor of the present invention includes: a single crystal silicon substrate 1; a porous silicon layer 2, which is formed on the surface of the single crystal silicon substrate 1 The upper surface has a thickness downward, and a silicon dioxide film is formed on the upper surface and the surface of the hole wall of the porous silicon layer 2; the heat insulating groove 3 is formed on the lower surface of the single crystal silicon substrate 1, and the heat insulating The groove 3 is an undercut groove, the bottom surface of the heat insulating groove 3 is located directly below the porous silicon layer 2, and the wall and bottom surface of the heat insulating groove 3 are provided with one or more groove groups, wherein each groove group includes A plurality of trenches 31 arranged in parallel; the lower i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com