Integral autoclaved aerated concrete wallboard and production process thereof

A technology of autoclaved air filling and concrete slabs, which is applied in the treatment of walls and building materials, building materials, etc. It can solve the problems that the wall and the outer mortar are difficult to be tightly combined, damaged, and cannot be installed and used again.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

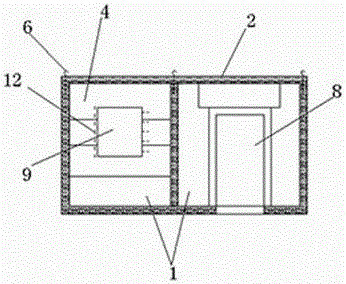

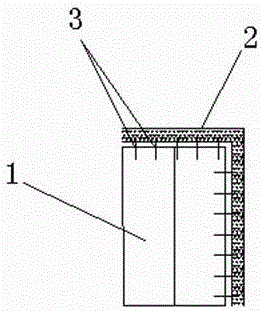

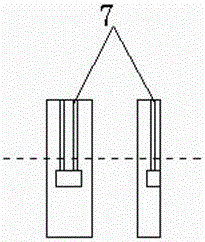

[0023] Such as figure 1 , 2 , 5, and 6, the autoclaved aerated concrete integral wallboard provided by the present invention includes an autoclaved aerated concrete panel 1 (ALC panel), a reinforced concrete frame 2, steel pins or / and bolts 3, autoclaved aerated concrete One side of the air-entrained concrete slab 1 is provided with a groove 1a, and the other side is provided with a protrusion 1b, and the groove 1a is matched with the protrusion 1b; hole groove 1c; or both sides of the autoclaved aerated concrete slab 1 are planes; When the air-entrained concrete slab 1 is installed vertically, a reinforcing rib 5 is provided at the junction of every other or several autoclaved aerated concrete slabs 1; A reinforcing rib 5 is arranged at the junction of the autoclaved aerated concrete slab 1; the reinforced concrete frame 2 is made of a concrete pouring steel mesh cage 11, and the reinforced concrete frame 2 is fixedly connected to the wall surface by steel pins or / and bolts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com