Large-dimension B4C-Al neutron absorption plate and preparation method thereof

A neutron absorption plate, large-scale technology, applied in shielding, nuclear engineering, reactors, etc., can solve the problems of increased defects and large energy consumption, and achieve the effect of protecting the edge of the blank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

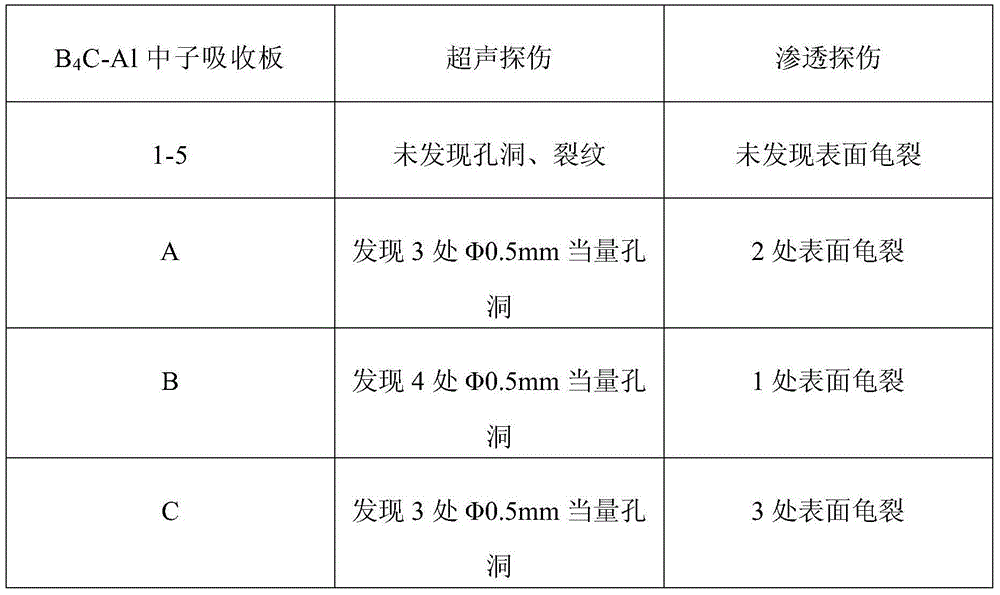

Embodiment 1

[0031] (1) Take boron carbide powder with an average Fischer particle size of 30 μm, aluminum powder with an average Fischer particle size of 30 μm, and silicon powder with an average Fischer particle size of 10 μm at a mass ratio of 25:74.4:0.6 to take 10Kg of powder and place it in a three-dimensional In the mixer, the ball-to-material ratio is 3:1, and the mixture is mixed for 6 hours to obtain a mixed powder with a Fischer average particle size of 20 μm; the purity of the boron carbide powder, aluminum powder and silicon powder used are all 99.8%;

[0032] (2) Put the mixed powder into the package to ensure that the relative packing density is 80v%, and vacuumize the package at 200°C to 2×10 -3 Seal after Pa, carry out hot isostatic pressing on the sealed sheath, the pressure is 80MPa, the temperature is 600°C, the time is 20min, the relative density of the blank after hot isostatic pressing is 99% (at 4°C) water density as a reference);

[0033] (3) Remove the sheath on ...

Embodiment 2

[0036](1) Take 10Kg of boron carbide powder with an average Fischer particle size of 50 μm, aluminum powder with an average Fischer particle size of 70 μm, and silicon powder with an average Fischer particle size of 10 μm at a mass ratio of 50:49.4:0.6, and place them in a three-dimensional In the mixer, the ratio of ball to material is 3:1, and the mixed powder with Fischer's average particle size of 40 μm is obtained after mixing for 10 hours; the purity of boron carbide powder, aluminum powder and silicon powder used is 99.9%;

[0037] (2) Put the mixed powder into the package to ensure that the relative packing density is 70v%, and vacuumize the package at 350°C to 1×10 -3 Seal after Pa, heat isostatic pressure treatment on the sealed package, the pressure is 150MPa, the temperature is 400°C, the time is 20min, the relative density of the billet after hot isostatic pressing is 99.1% (in 4°C water The density is a reference);

[0038] (3) Remove the sheath on the outer sid...

Embodiment 3

[0041] (1) Take 10Kg of boron carbide powder with an average Fischer particle size of 0.5 μm, aluminum powder with an average Fischer particle size of 5 μm, and silicon powder with an average Fischer particle size of 10 μm in a mass ratio of 29.4:70:0.6, and place in In the three-dimensional mixer, the ball-to-material ratio is 3:1, and the mixed powder with Fischer's average particle size of 3.5 μm is obtained after mixing for 7 hours; the purity of boron carbide powder, aluminum powder and silicon powder used are all 99.7%;

[0042] (2) Put the mixed powder into the bag to ensure that the relative packing density is 80v%, and vacuumize the bag at 300°C to 2×10 -3 Seal after Pa, heat isostatic pressure on the sealed package, the pressure is 100MPa, the temperature is 500°C, the time is 20min, the relative density of the billet after hot isostatic pressing is 99.2% (in 4°C water The density is a reference);

[0043] (3) Remove the sheath on the outside of the billet, and carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com