Diversified engineered safety system for nuclear reactor

A safety system and nuclear reactor technology, applied in the field of reactor safety facilities, can solve problems such as inability to continue effective operation indefinitely, failure to establish passive waste heat discharge channels, failure to maintain long-term safety of the reactor, etc., to improve safety and improve accident mitigation ability to ensure long-term safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

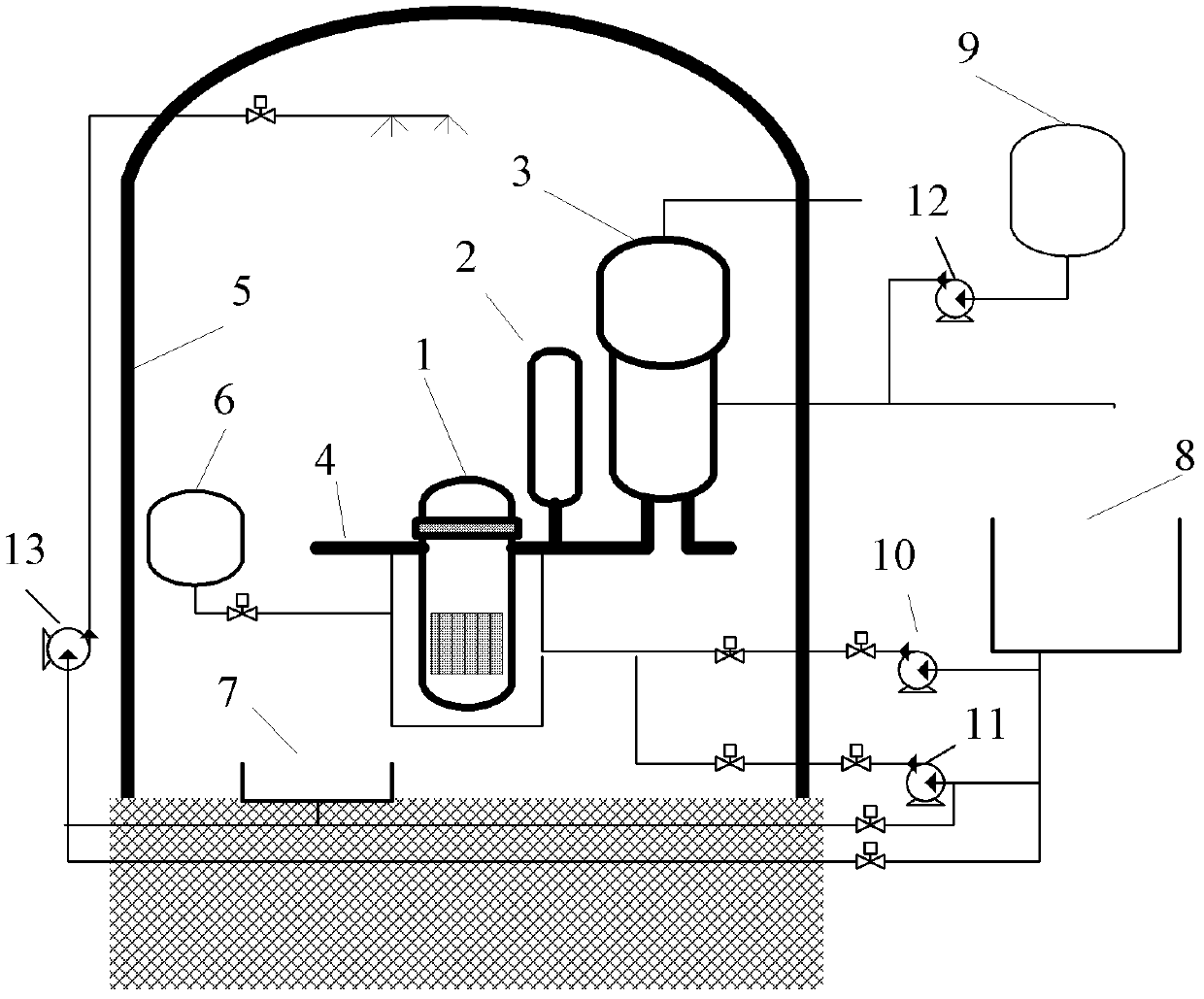

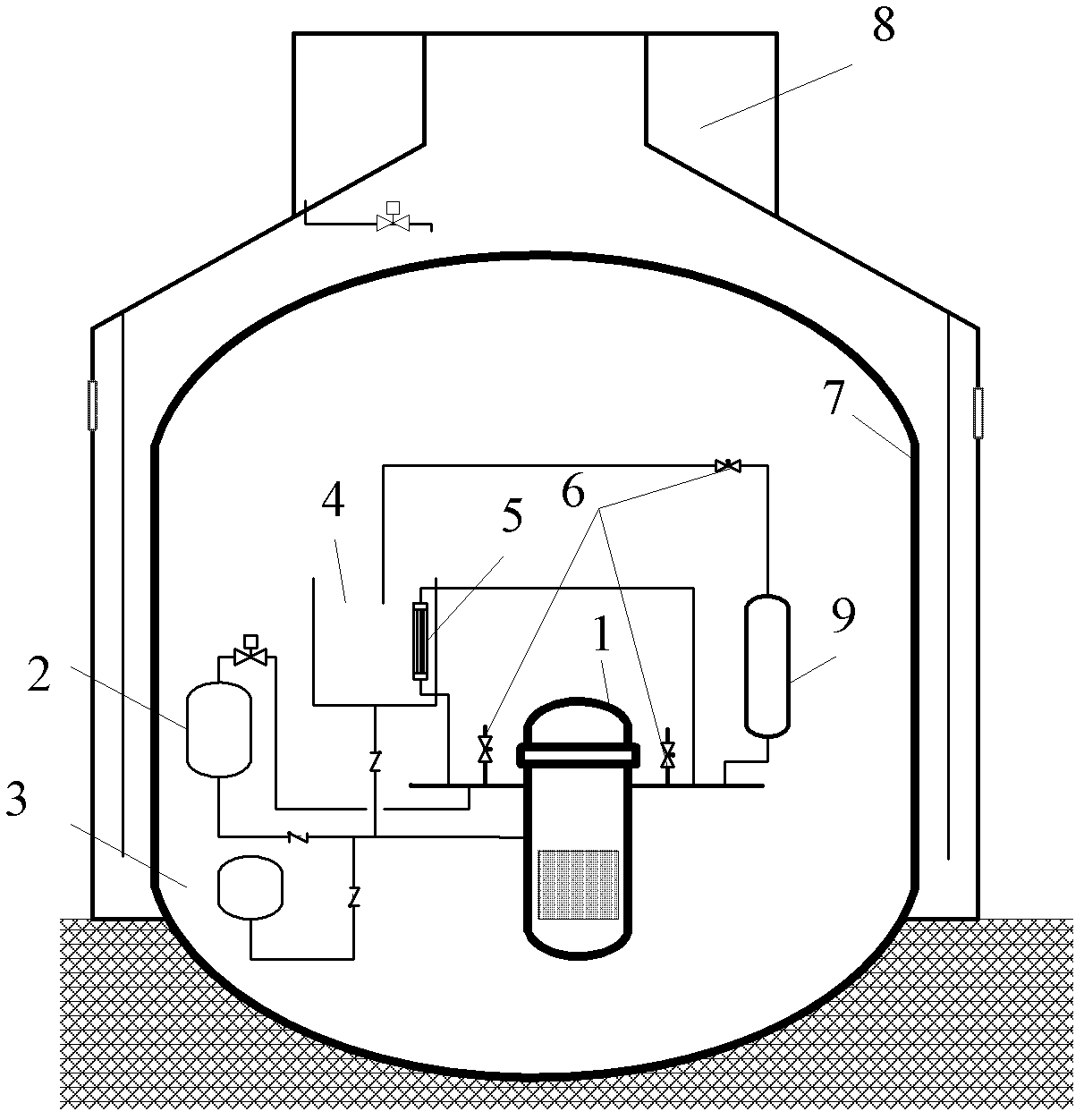

[0039] Such as image 3 As shown, the diversified special safety system of the present invention includes 5 subsystems: the primary circuit passive waste heat discharge subsystem 4, the secondary side passive waste heat discharge subsystem 6 of the steam generator relying on gravity to inject feed water, and the full-pressure active waste heat discharge subsystem 6. Waste heat removal subsystem 3, low-pressure passive safety injection subsystem 5, passive containment cooling subsystem 9 combining water flooding and air cooling.

[0040] The passive waste heat removal subsystem 6 on the secondary side of the steam generator, the passive safety injection subsystem 5 and the passive containment cooling subsystem 9 combining water flooding and air cooling are firstly described below.

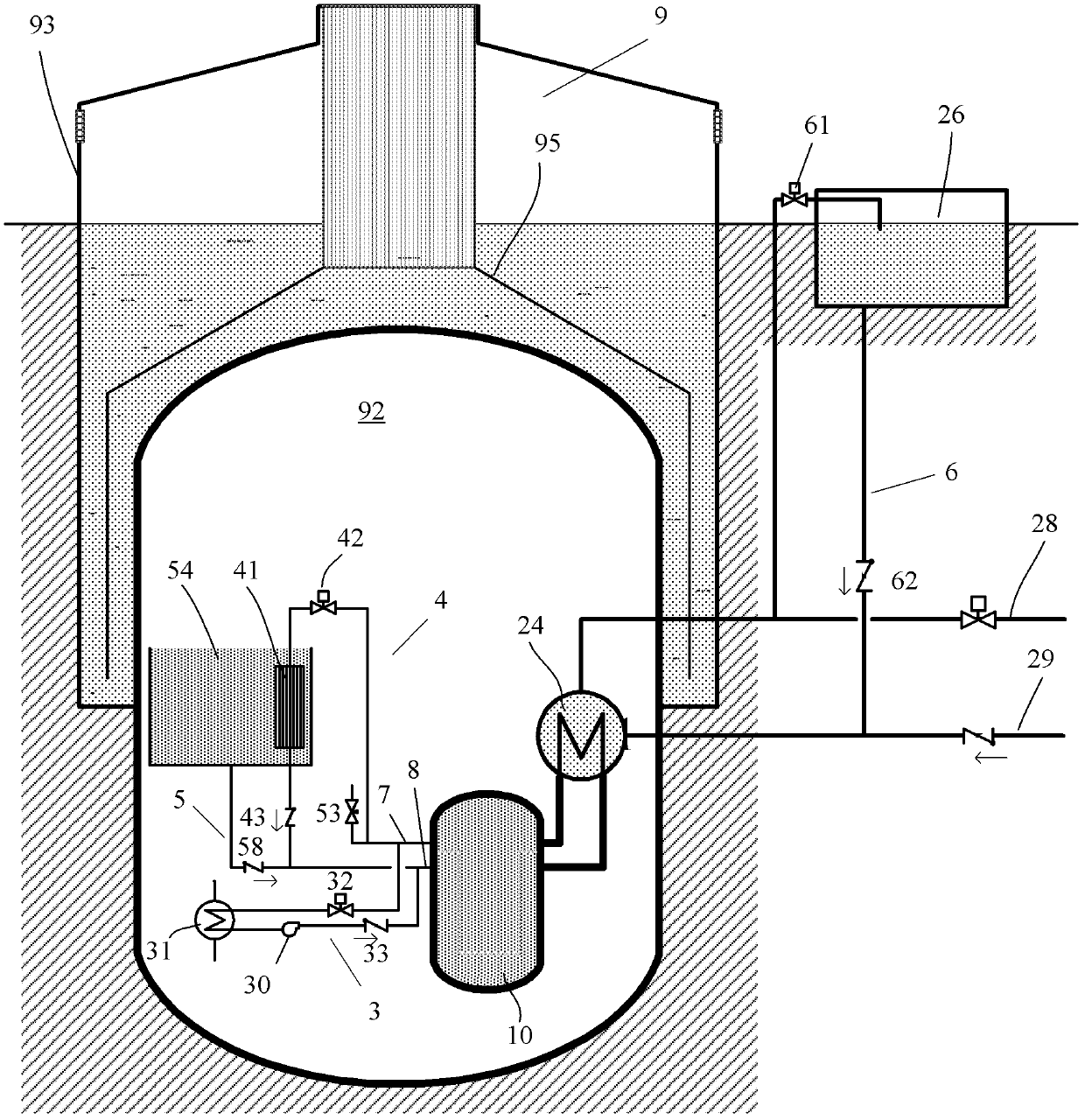

[0041] Such as Figure 4 As shown, the passive waste heat removal subsystem 6 on the secondary side of the steam generator includes a passive feed water tank 26 and a steam generator 24 . The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com