Simulated work condition detecting method for 50,000 ton/year methionine propylene oxidation reactor

An oxidation reactor, methionine propylene technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the owner's economic loss, repair difficulties and other problems, to avoid economic loss and ensure long-term safety of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

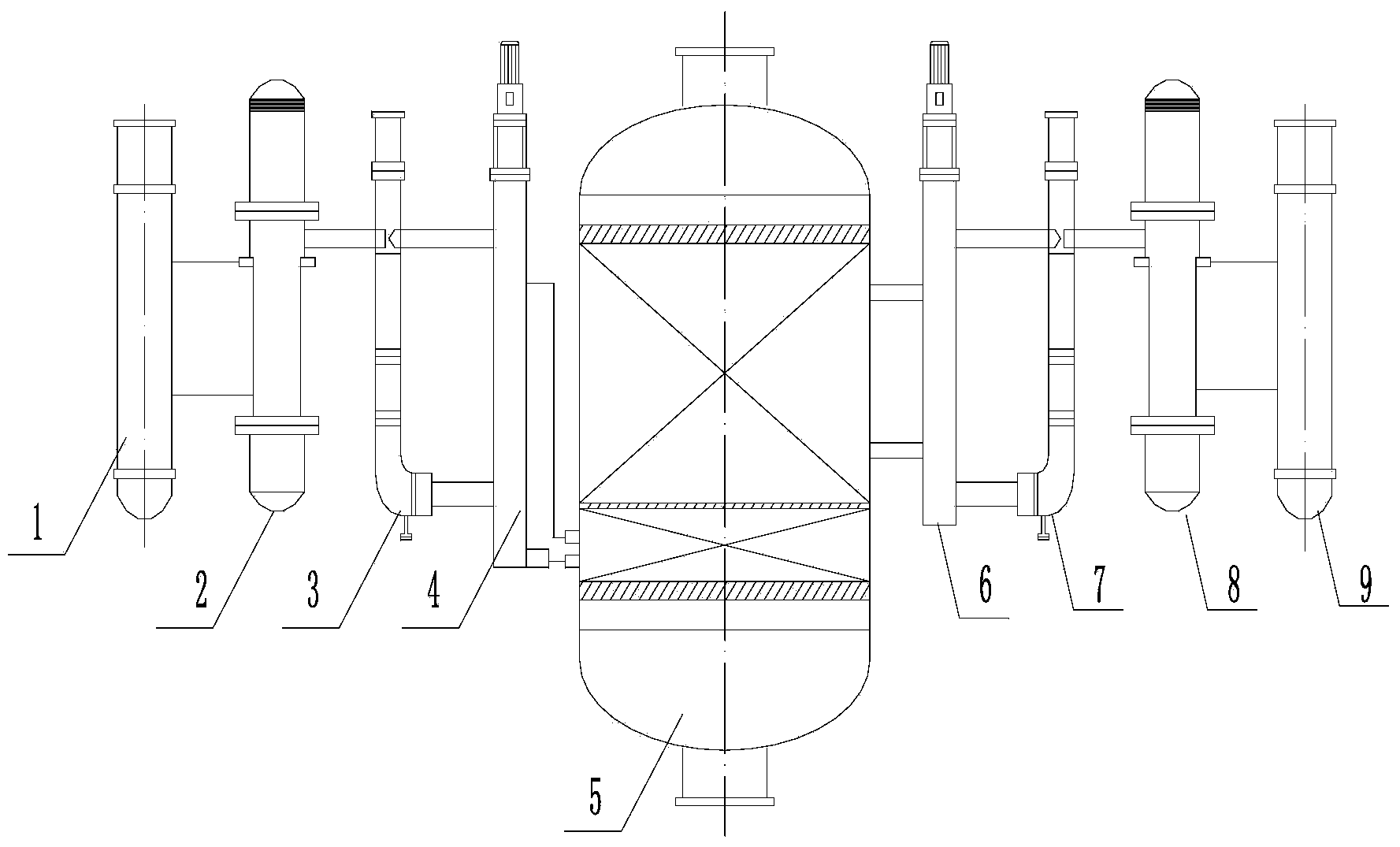

Image

Examples

Embodiment Construction

[0015] Install a 50,000-ton / year methionine propylene oxidation reactor on site, and use the present invention to carry out simulated working condition inspection:

[0016] 1. Blow hot air to the tube side of the oxidation reactor to raise the temperature of the reactor to 160°C ~ 170°C, and the temperature rise rate is not greater than 8°C per hour; at the same time, heat up the cooler and other equipment and pipelines, the temperature and reaction device remains consistent;

[0017] 2. Inject salt into the reaction section of the oxidizer. Open all the high-level exhaust ports, wait until the molten salt tank overflows when the reaction section is filled with molten salt, then turn on the molten salt pump in the reaction section, and turn on the electric heater to gradually increase the temperature of the reaction section and keep it at 4-8°C / hour.

[0018] 3. The temperature of the reaction section is raised to 340°C to 350°C for 24 hours.

[0019] 4. Check whether there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com