Full-automatic sterilizing quality-guaranteeing steamer and sterilizing technology

A fully automatic, steamer technology, applied in food preservation, food processing, food science, etc., can solve the problems of heating up, increasing pressure quickly, and not overcoming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and examples.

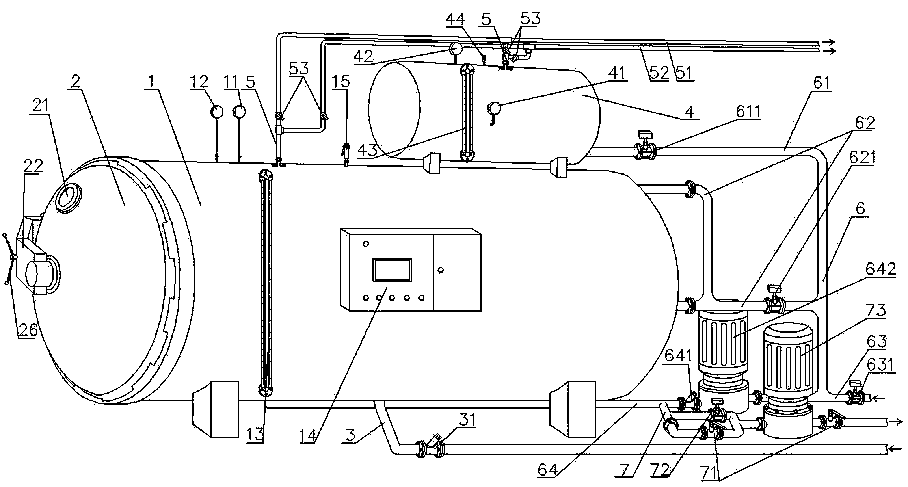

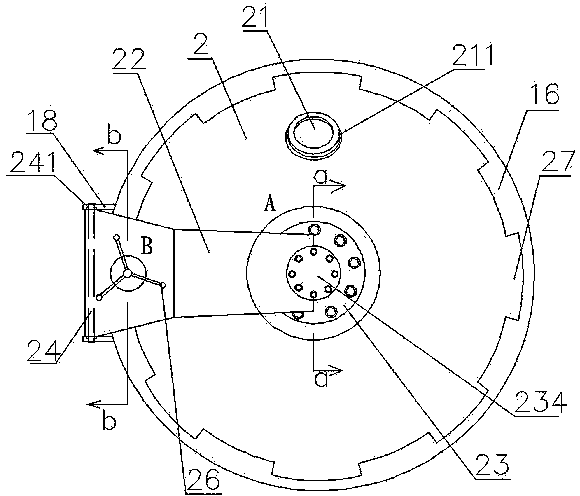

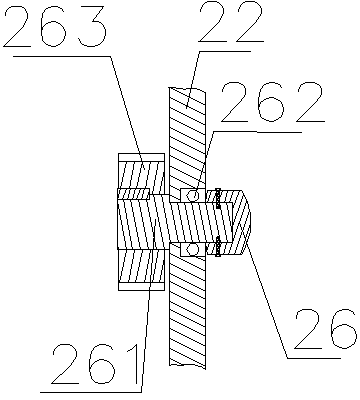

[0052] see Figure 1-Figure 8 , this embodiment includes: a pot body 1, a pot cover 2, a steam pipe 3, a return water storage tank 4, an exhaust pipe 5, a water circulation pipeline 6 and a drain pipe 7, and the water circulation pipeline 6 includes a return water pipe 61, Spray main pipe 62, water inlet pipe 63 and water outlet pipe 64, four are connected with each other; Described pot body 1 is equipped with thermometer-11, pressure gauge-12, water temperature gauge-12 and pressure reducing valve-15, and pot body 1 is also connected with automatic control box 14; described backwater storage tank 4 is equipped with thermometer two 41, pressure gauge two 42, water temperature gauge two 43 and pressure reducing valve two 44, backwater storage tank 4 and automatic control box 14 connection; the described pot cover 2 is connected with the pot body 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com