Manufacturing method of valve part

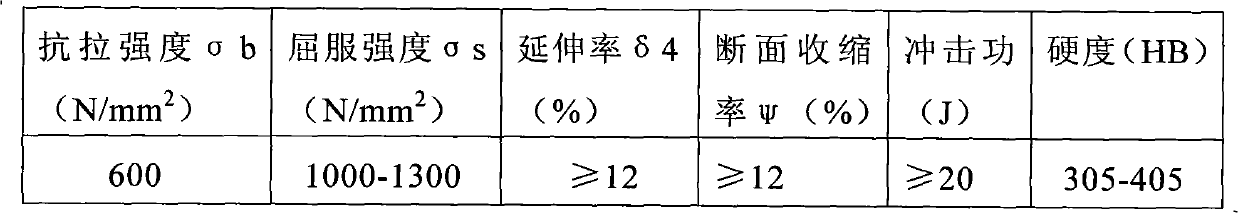

A manufacturing method and technology of parts, applied in the field of structural design of valves, can solve problems such as high mechanical properties, metallographic flaw detection requirements, affecting the development of steam turbines, and small forging temperature range, so as to avoid central cracks, cracking, and deformation resistance Strong, guaranteed eligibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Take the electroslag remelting ingot blank with a diameter of 480mm for forging, and open the billet to a diameter of 300mm. The forging ratio is ≥ 2.5 when the billet is opened, and then it is polished and finished. After the flaw detection, the blank is ready for the second stage forging;

[0025] (2) Heat the above blank to 1150°C, keep it warm for 90 minutes, and then perform upsetting, elongating, upsetting, elongating, chamfering, splitting, elongating and rounding of the billet, the total forging ratio is > 5, and Classified forging according to the shape, the last reserved deformation is more than 20%, and the finished part is locally heated and wrapped with high-temperature cotton into the furnace or partially heated, the heating temperature is reduced to 1060 ° C, and the holding time is ≤ 0.25 min per 1 mm section;

[0026] (3) Process the obtained blank, and perform ultrasonic flaw detection inspection, and carry out 100% inspection according to 3b-3c in...

Embodiment 2

[0037] (1) Take the electroslag remelting ingot blank with a diameter of 480mm for forging, and open the billet to a diameter of 300mm. The forging ratio is ≥ 2.5 when the billet is opened, and then it is polished and finished. After the flaw detection, the blank is ready for the second stage forging;

[0038] (2) Heat the above-mentioned blank to 1140°C, keep it warm for 90 minutes, and then carry out upsetting, drawing, upsetting, drawing, chamfering, splitting, drawing and rounding of the blank. The total forging ratio is >5, And graded forging according to the shape, the last reserved deformation is more than 20%, and the finished part of the local heating is wrapped with high-temperature cotton into the furnace or partially heated, the heating temperature is reduced to 1050 ° C, and the holding time is ≤ 0.25 min per 1 mm section;

[0039] (3) Process the obtained blank, and perform ultrasonic flaw detection inspection, and carry out 100% inspection according to 3b-3c in ...

Embodiment 3

[0045] (1) Take the electroslag remelting ingot blank with a diameter of 480mm for forging, and open the billet to a diameter of 300mm. The forging ratio is ≥ 2.5 when the billet is opened, and then it is polished and finished. After the flaw detection, the blank is ready for the second stage forging;

[0046] (2) Heat the above blank to 1140-1160°C, keep it warm for 90 minutes, and then perform upsetting, elongating, upsetting, elongating, chamfering, splitting, elongating and rounding of the billet, the total forging ratio > 5. Forging in stages according to the shape, the last reserved deformation is > 20%, local heating has been finished with high-temperature cotton wrapped into the furnace or local heating, the heating temperature is reduced to 1080 ° C, and the holding time is ≤ 0.25 min per 1 mm section;

[0047] (3) Process the obtained blank, and perform ultrasonic flaw detection inspection, and carry out 100% inspection according to 3b-3c in Table 2 of EN 10228-4 sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com