Method for producing super-thick plate by packrolling welding process

A technology of super-thick plate and stack rolling welding, which is applied in the field of steel rolling in the metallurgical industry, can solve the problems of high cost and cumbersome debugging, and achieve the effect of low cost, good internal quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The ordinary Q345 continuous casting slab is used to produce a 150mm extra-thick plate.

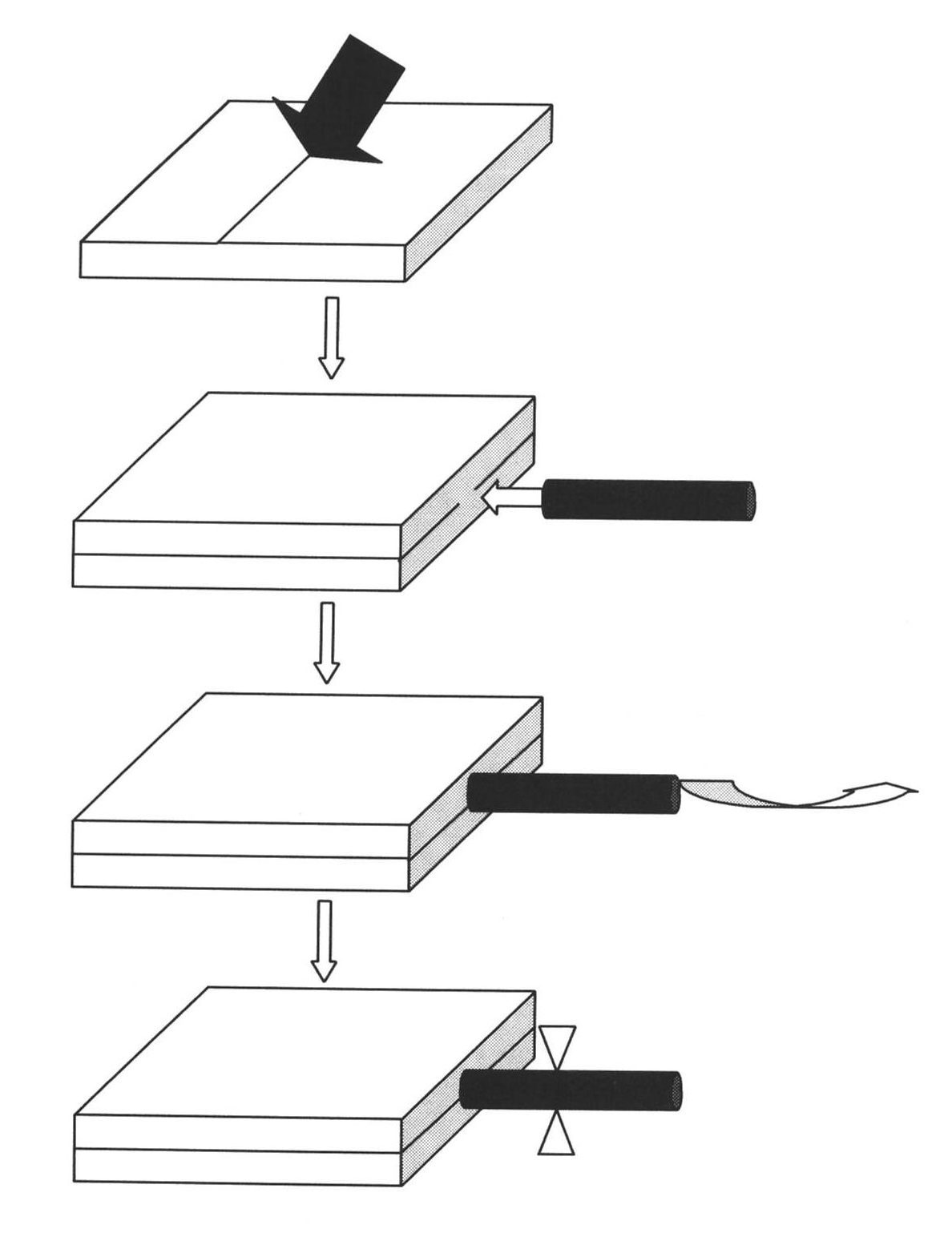

[0028] The continuous casting slab was cut into two billets with dimensions of 250mm×2500mm×2500mm by flame cutting. figure 1 Process flow chart of surface cleaning-welding blank assembly-vacuumizing-sealing designed for the present invention. Use a gantry planer to remove the iron oxide scale on the surface of the two blocks to be bonded, and then blow off the surface with compressed air; align and overlap the two blocks, and fasten them on the trolley, and use an argon arc welding machine for compounding The welding seal around the gap leaves a 10mm long opening at one end, and then welds a soft steel pipe on the opening (the thickness of the pipe wall is above 3mm to ensure sufficient compression during pressing); use a vacuum pump to pump through the steel pipe Vacuum to 1×10 -2 pa, finally use hydraulic pliers to press and seal the steel pipe (shorten the lengt...

Embodiment 2

[0029] Embodiment 2: An extra-thick plate of 250 mm is produced by using ordinary Q345 continuous casting slab.

[0030] Cut the continuous casting slab into three pieces of 250mm×2500mm×2500mm by flame cutting; use the gantry planer to remove the iron oxide scale on the surface of the two pieces of slabs to be joined, and then blow off the surface with compressed air; Align, superimpose, and fasten on the trolley, use argon arc welding machine to weld and seal around the two composite gaps, leave a 10mm long opening at one end of each composite surface, and then weld a thicker material on the opening. Soft steel pipe (thickness of the pipe wall is more than 3mm to ensure sufficient compression during pressing); use a vacuum pump to evacuate through the steel pipe to 1×10 -2 pa, finally use hydraulic pliers to press and seal the steel pipe (shorten the length of the steel pipe on the combined slab as far as possible, and stop the vacuum pump after pressing), and seal the press...

Embodiment 3

[0031] Embodiment 3: A 150mm extra-thick plate is produced by continuously casting a low-carbon bainitic steel slab.

[0032] Cut the continuous casting slab into three pieces of 150mm×2500mm×2500mm by flame cutting; use the gantry planer to remove the iron oxide scale on the surface of the two pieces of slabs to be joined, and then blow off the surface with compressed air; Align, superimpose, and fasten on the trolley, use argon arc welding machine to weld and seal around the two composite gaps, leave a 10mm long opening at one end of each composite surface, and then weld a thicker material on the opening. Soft steel pipe (thickness of the pipe wall is more than 3mm to ensure sufficient compression during pressing); use a vacuum pump to evacuate through the steel pipe to 1×10 -2 Pa, finally use hydraulic tongs to press and seal the steel pipe (shorten the length of the steel pipe on the combined slab as much as possible, and stop the vacuum pump after pressing), and seal the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com