Leveler roll and manufacturing process thereof

A straightening roll and process technology, applied in the field of metallurgical roll manufacturing, can solve the problems of poor wear resistance and scratch resistance, difficult uniformity of roll surface hardness, short service life, etc., to ensure high wear resistance, The effect of improving purity, improving toughness and resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

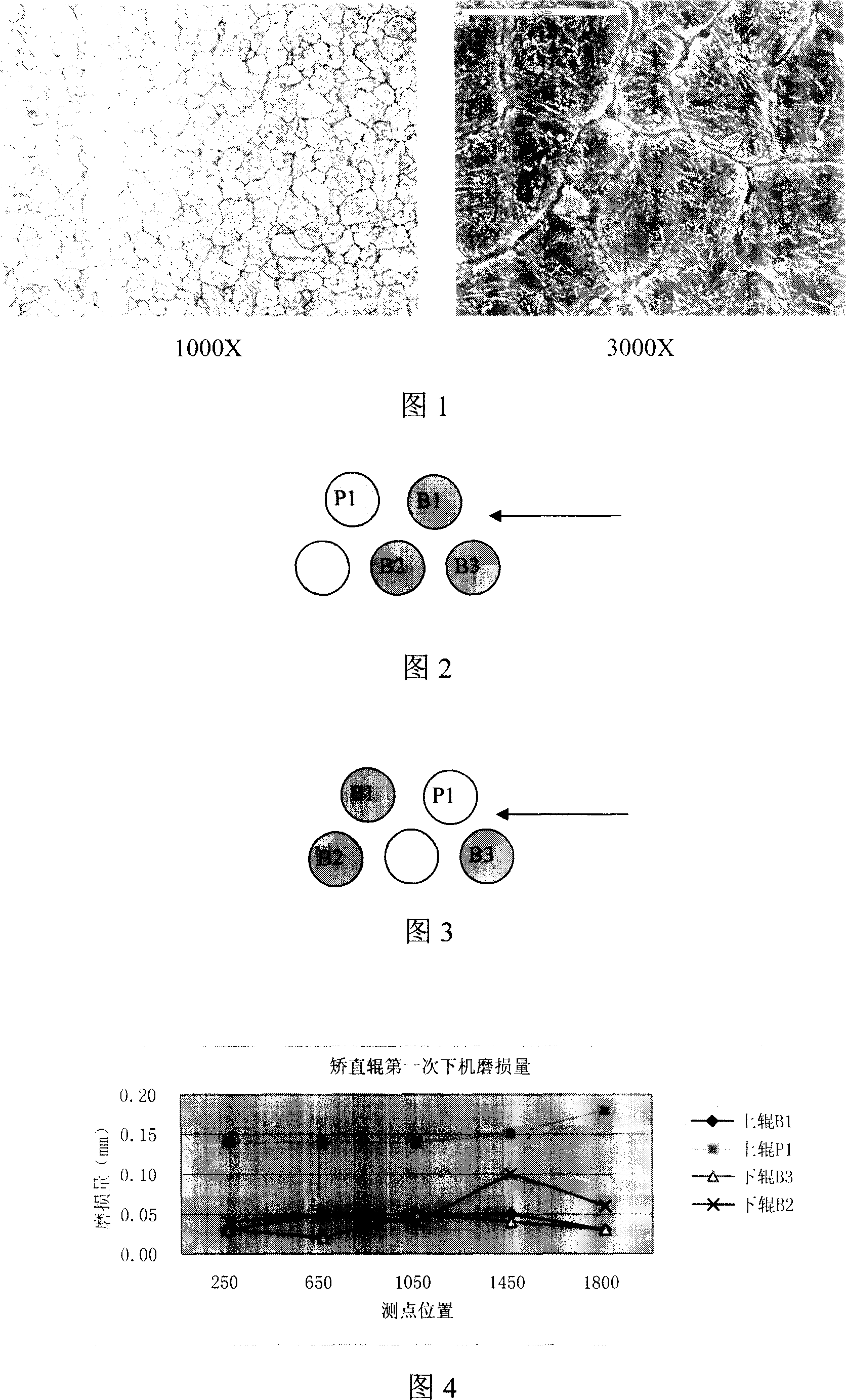

Image

Examples

Embodiment Construction

[0031] Now implement the novel straightening roll of the present invention respectively by chemical composition shown in table 2.

[0032] The chemical composition (percentage by weight) of table 2 straightening roller of the present invention

[0033] C

Si

mn

Ni

Cr

Mo

V

P

S

0.85

0.30

0.40

2.10

0.30

0.10

0.025

0.021

Example 1

1.10

1.00

0.60

0.20

4.00

0.20

0.10

0.015

0.008

Example 2

0.85

0.40

0.40

0.50

6.00

0.40

0.50

0.015

0.008

[0034] Example 4

0.95

0.20

0.40

1.00

6.00

0.50

0.20

0.015

0.008

Example 5

0.60

0.60

0.40

0.50

5.00

0.50

0.20

0.015

0.008

[0035] Manufacture novel straightening roller o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com