A kind of high temperature resistant martensitic stainless steel and its manufacturing method

A martensitic stainless steel and manufacturing method technology, applied in the field of metallurgy, can solve the problems of reduced yield, high smelting cost, and large metal loss, so as to reduce production cost and production cycle, low electroslag smelting cost, and reduce the cost of steel The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

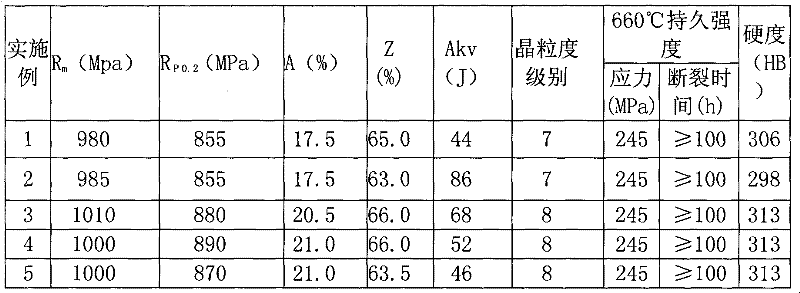

Examples

Embodiment 1-5

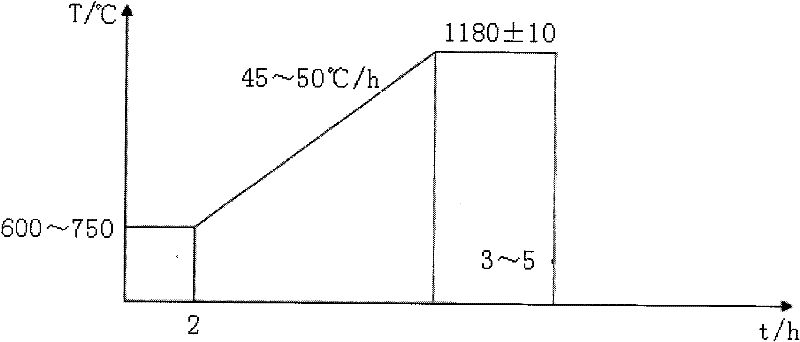

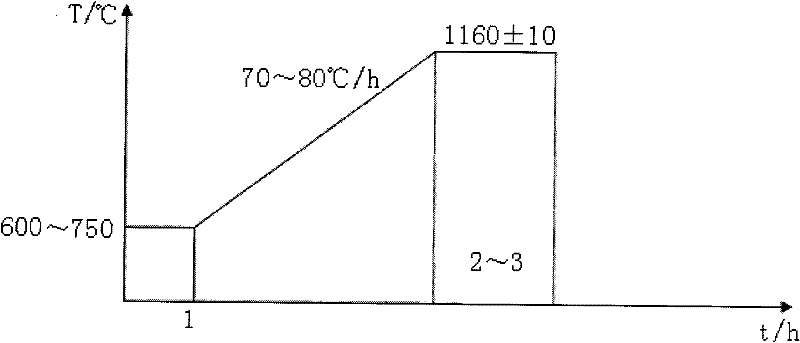

[0036] Follow the steps below to produce high temperature resistant martensitic stainless steel:

[0037] (1) Select high-purity metal chromium, chromium nitride, metal niobium or ferroniobium, metal molybdenum or ferro-molybdenum, metal tungsten or tungsten-ferro, and aluminium-iron and other furnace materials, and select raw materials with low impurity element content to put into vacuum induction In the furnace, the content of impurity elements is controlled to the lowest level for smelting. In order to ensure that the N element composition of the electrode rod cast by vacuum induction smelting enters the control specification, Ar is poured into the furnace to 333mbar before pouring, and then ferrochromium nitride is added. Improve the yield of N elements. During electroslag remelting, in order to prevent the burning of Nb element, aluminum powder is evenly coated on the electrode rod, and the mass percentage of Nb element in the electrode rod is controlled according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com