Production method for steel ingot of large-sized high-nitrogen retaining ring steel

A production method and large-scale technology, applied in the field of high-nitrogen steel, can solve problems such as difficult control of nitrogen content, quality of dropped steel ingots, and uncomplicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

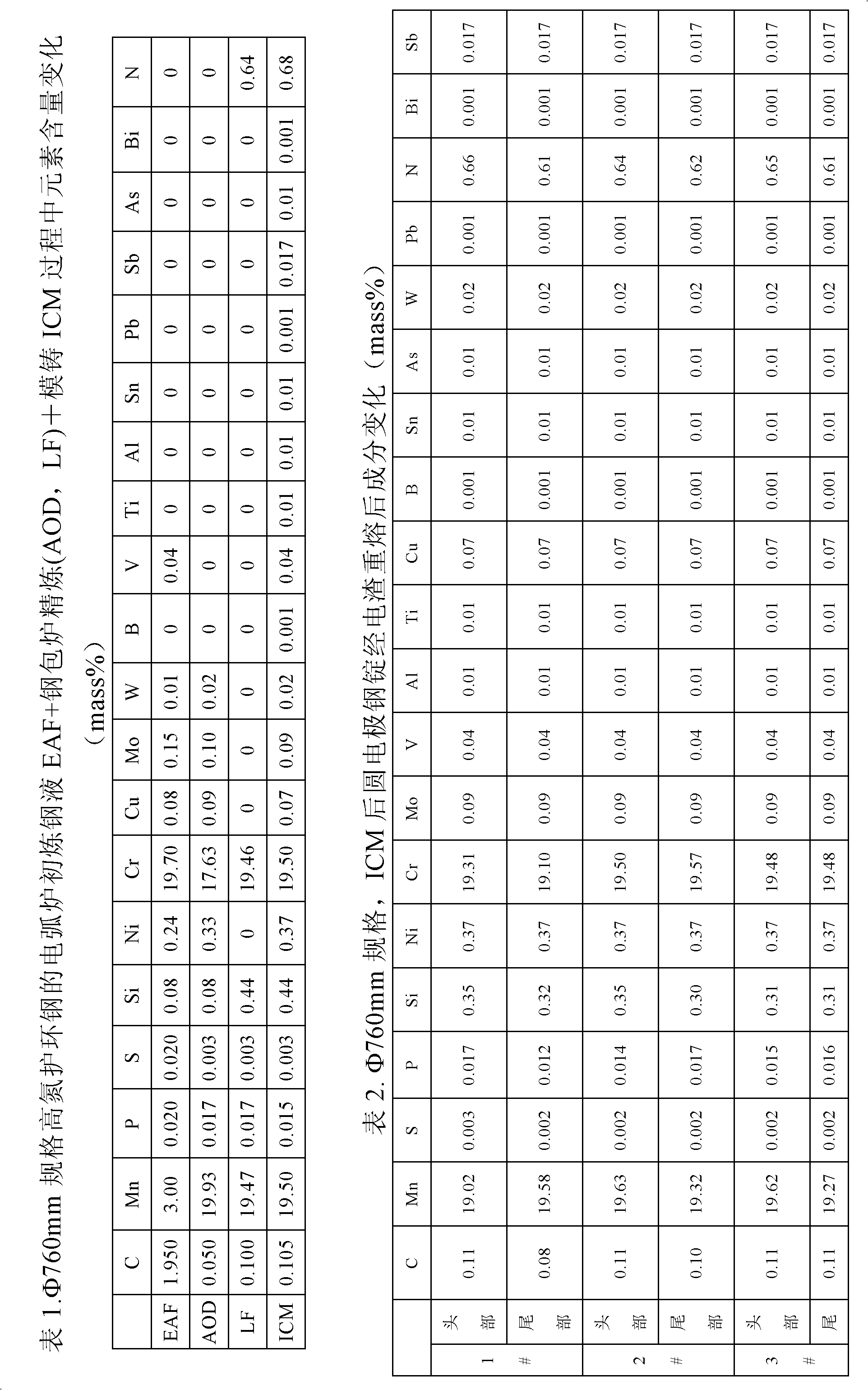

[0031] For the production of high-nitrogen guard ring steel ingots with a specification of Φ760mm, the specific implementation methods are as follows:

[0032] 1) Smelting and casting

[0033] Raw material batching optimization, the present invention is aimed at a 40-ton electric arc furnace, selects low-phosphorus, low-sulfur, low-titanium and low-copper clean scrap steel, cut ends and other return materials, direct reduced iron and high-quality pig iron as metal raw material ingredients, and the specific ratio is clean scrap steel + Direct reduced iron = 75%, high-quality pig iron 25%, to meet the requirements of Cu, Sn, As, Sb, Pb and other residual elements in steel; alloys: high-carbon ferrochromium, electrolytic manganese, ferrochromium nitride and manganese nitride Iron; reducing agent: aluminum particles, ferrosilicon, silicon balls, silicon carbide; slagging agent: quicklime, fluorite, MgO.

[0034] Electric arc furnace primary molten steel EAF + ladle furnace refini...

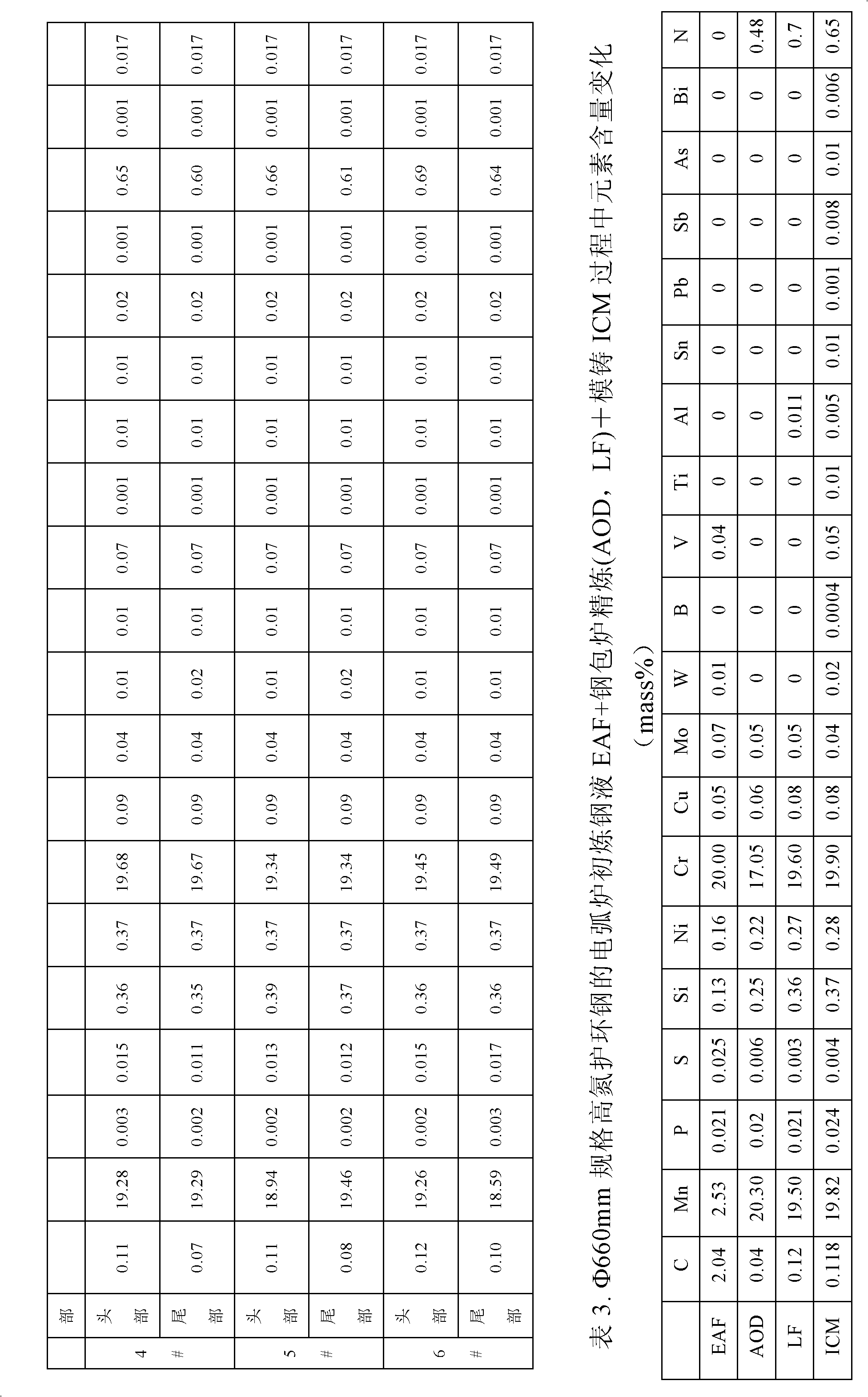

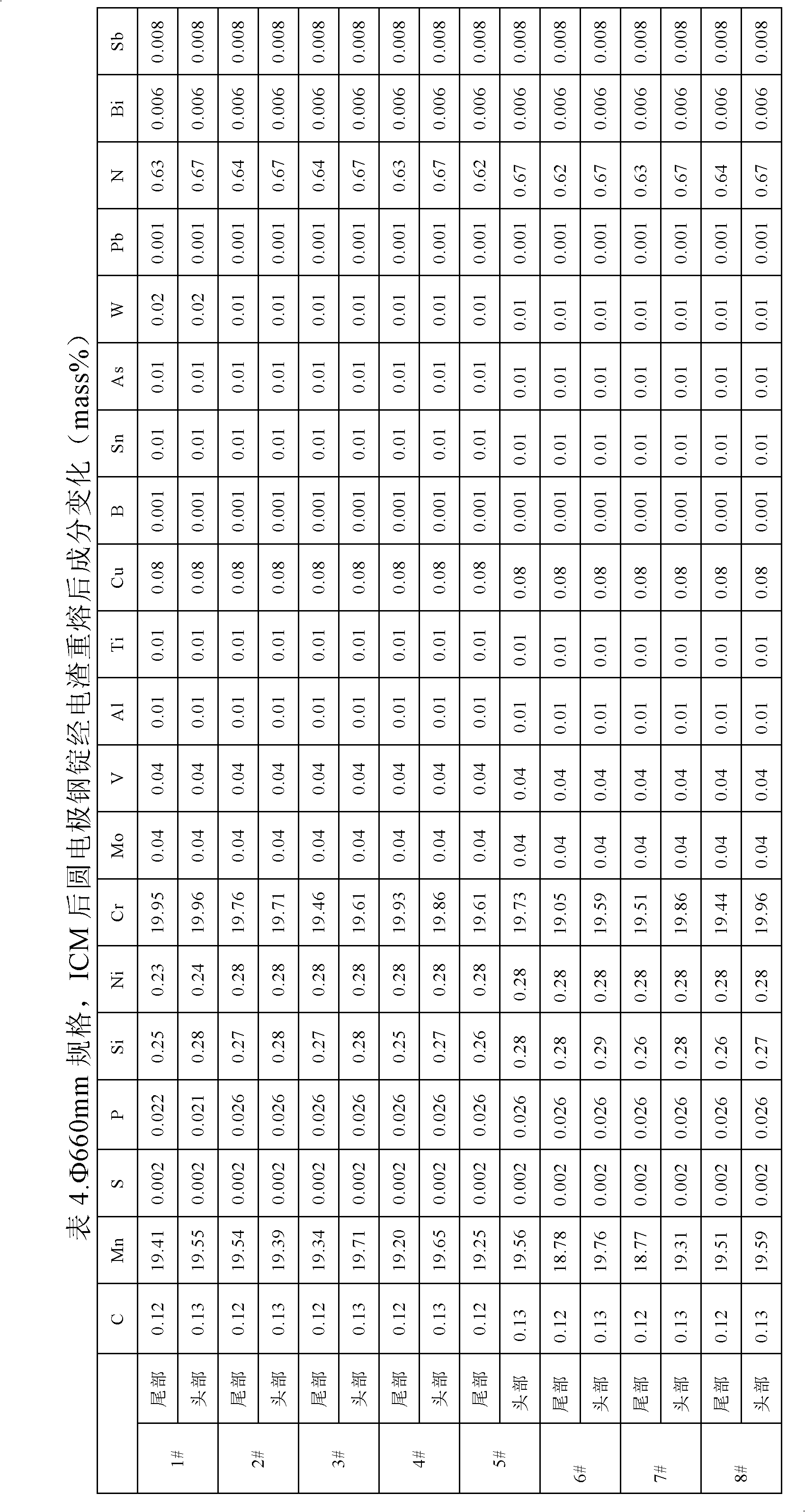

Embodiment 2

[0049] For the production of high-nitrogen guard ring steel ingots with a specification of Φ660mm, the specific implementation methods are as follows:

[0050] 1) Smelting and casting

[0051] Raw material batching optimization, the present invention is aimed at a 40-ton electric arc furnace, selects low-phosphorus, low-sulfur, low-titanium and low-copper clean scrap steel, cut ends and other return materials, direct reduced iron and high-quality pig iron as metal raw material ingredients, and the specific ratio is clean scrap steel + Direct reduced iron = 75%, high-quality pig iron 25%, to meet the requirements of Cu, Sn, As, Sb, Pb and other residual elements in steel; alloys: high-carbon ferrochromium, electrolytic manganese, ferrochromium nitride and manganese nitride Iron; reducing agent: aluminum particles, ferrosilicon, silicon balls, silicon carbide; slagging agent: quicklime, fluorite, MgO.

[0052] Electric arc furnace primary molten steel EAF + ladle furnace refini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com