Production method of beer wheat juice containing low-fermentation sugar

A production method and low-fermentation technology, applied in the field of food processing, can solve the problems of high consumption of raw materials, low fermentable sugar content, and increased investment in equipment costs, and achieve economical guarantees, low raw material costs, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Whole Wheat Low Alcohol Beer Wort

[0022] Raw material ratio: malt 30% (m / m), caramel malt 5% (m / m), special malt 65% (m / m);

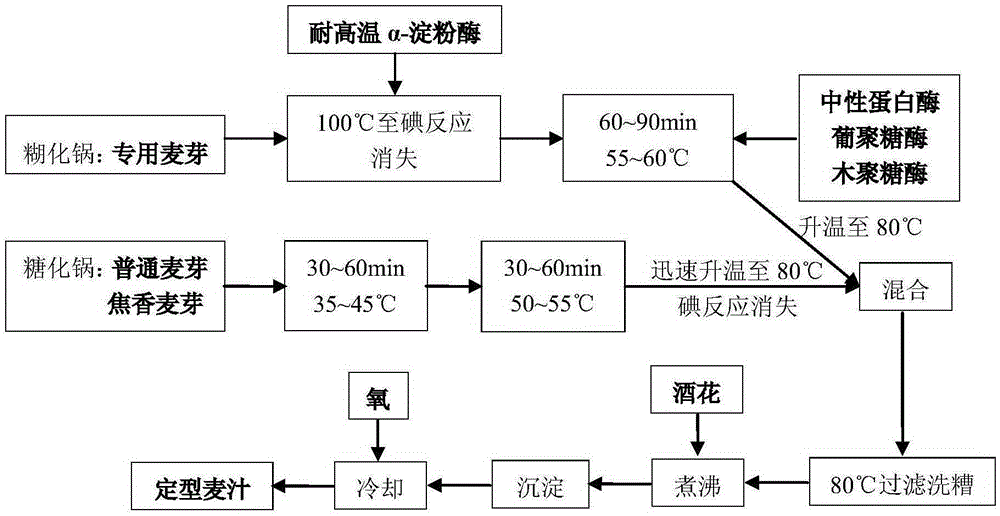

[0023] Prepare shaped wort according to the method of the present invention, the ratio of the weight of the saccharification raw material to the amount of feed water added is 1:4.5 (m / v), and the process is detailed in the attached figure 2 .

[0024] use figure 2 The limit fermentation degree of the finalized wort obtained by the method is 16%.

Embodiment 2

[0026] Whole Wheat Low Alcohol Beer Wort

[0027] Raw material ratio: malt 15% (m / m), caramel malt 5% (m / m), special malt 80% (m / m);

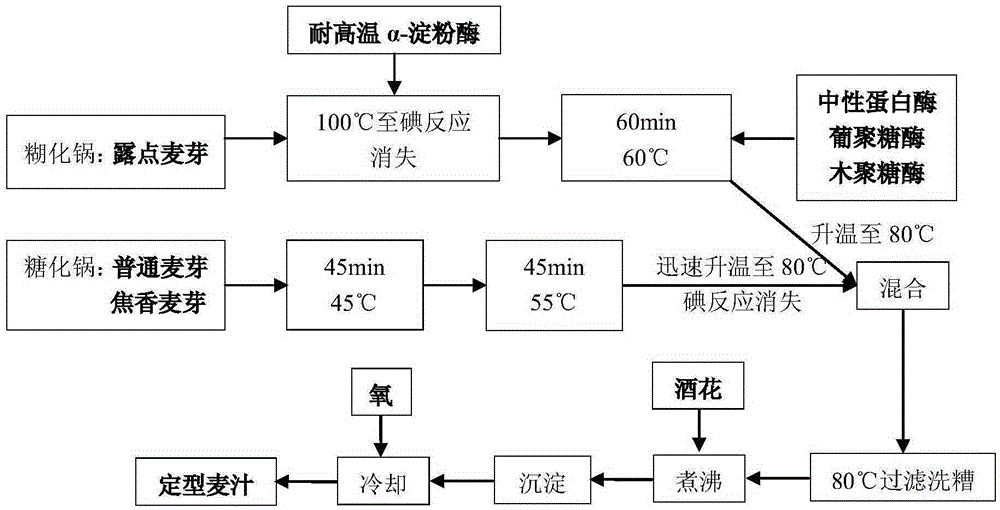

[0028] Prepare shaped wort according to the method of the present invention, the ratio of the weight of the saccharification raw material to the amount of feed water added is 1:4.0 (m / v), and the process is detailed in the attached image 3 .

[0029] use image 3 The limit fermentation degree of the finalized wort obtained by the method is 14%.

Embodiment 3

[0031] Wheat non-alcoholic beer wort

[0032] The ratio of raw materials is: malt 15% (m / m), caramel malt 5% (m / m), special malt 30% (m / m), special wheat malt 50% (m / m);

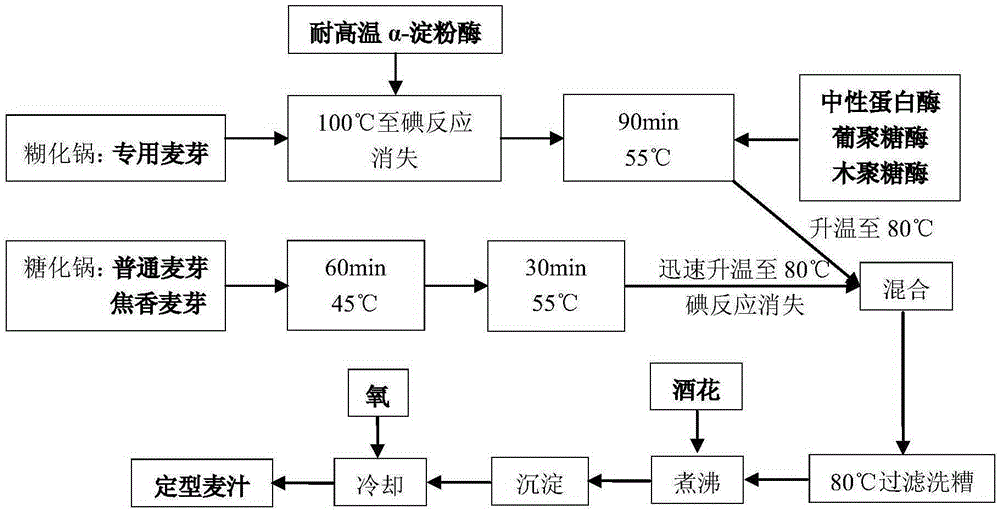

[0033] Prepare shaped wort according to the method of the present invention, the ratio of saccharification raw material weight and feed water addition is 1:5.0 (m / v), and process sees attached Figure 4 .

[0034] use Figure 4 The limit fermentation degree of the finalized wort obtained by the method is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com