Method and device for synchronously removing H2S, CO2 and SO2 from sulfur-containing mixed gas

A mixed gas, SO2 technology, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve problems such as difficulty in removing hydrogen sulfide, achieve strong flexibility, improve desulfurization capacity, and the effect of a simple and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

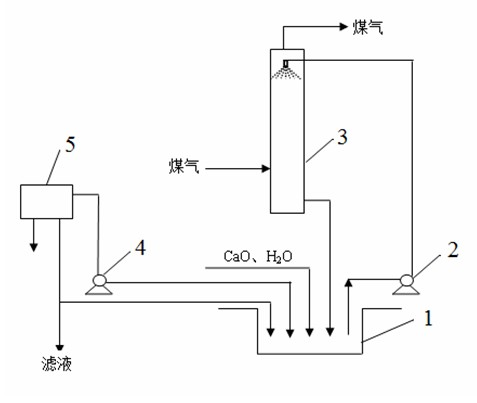

Embodiment 1

[0019] A simultaneous removal of H from sulfur-containing mixed gas 2 S, CO 2 and SO 2 method, first using lime aqueous solution to remove CO in the mixed gas 2 and SO 2 , and separated out as a precipitate, and then use caustic soda solution to remove H 2 S and the remaining small amount of CO 2 and SO 2 , and after the catalyst reaction, the final H 2 S is converted into sulfur foam products. In this method, two detergents are compounded and used in one process, and the mixed gas that can be treated can have high or low content of acidic components. Among them, the removal of H 2 The alkali washing process of S can be combined with the catalytic oxidation method, and can also be combined with the circulation absorption method. The desulfurization waste lye can be used as a supplementary alkali source for the distillation of residual ammonia and fixed ammonium decomposition.

Embodiment 2

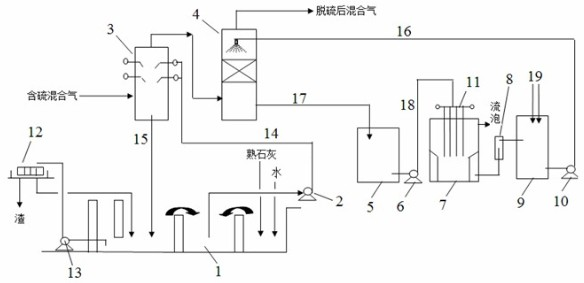

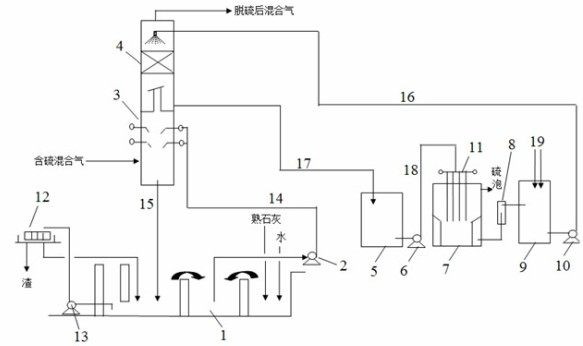

[0021] Such as figure 2 Shown is the two-tower special-purpose device of the present invention. The special device includes a combined washing tower, a lime water circulation tank 1, a caustic soda solution circulation tank 9, a filter 12, a rich liquid tank 5, a regeneration tower 7 and a liquid level regulator 8; the lime water circulation tank 1 passes through the lime water inlet pipe Road 14 and limewater outlet pipeline 15 communicate with the combined washing tower, and limewater circulation pump 2 is arranged on the limewater inlet pipeline 14; Described caustic soda solution circulation tank 9 communicates with the combined washing tower through the barren liquid pipe 16, in A lean liquid pump 10 is provided on the lean liquid pipe 16; a rich liquid pipe 17 communicates with the rich liquid tank 5 on the joint washing tower, and the rich liquid tank 5 communicates with the regeneration tower 7 through the regeneration pipe 18, and the regeneration pipe 18 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com