Technique for crushing and water washing of aggregates on asphalt pavement of high-speed highway

A kind of asphalt pavement and aggregate technology, applied in the direction of roads, roads, road repairs, etc., to achieve the effect of improving aggregate quality, enhancing adhesion, and reducing the content of weak particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

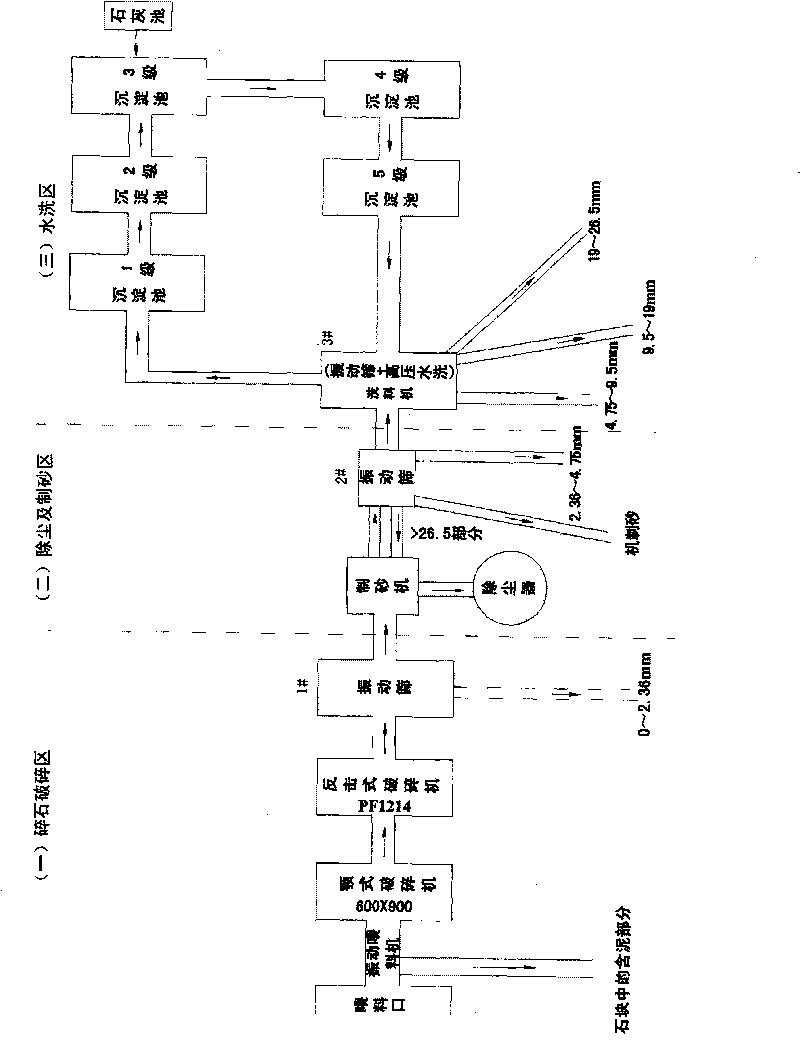

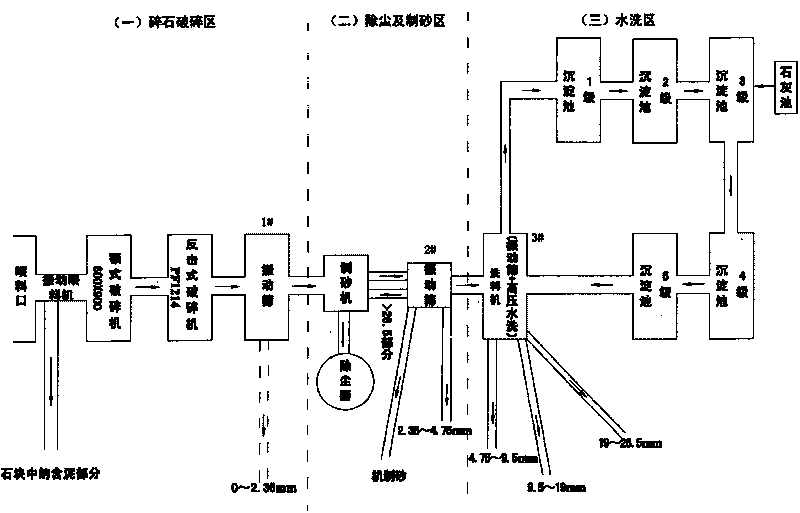

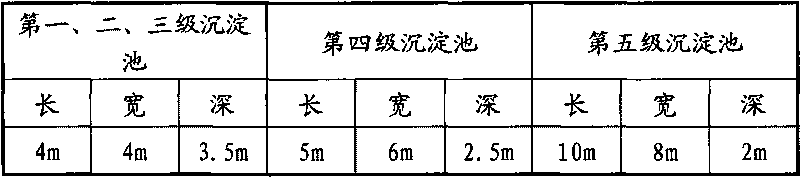

Method used

Image

Examples

Embodiment Construction

[0037] This example is the contract section of AP1 of Pengze-Hukou Expressway in Jiangxi Province. It is located in Pengze County, Jiujiang City, Jiangxi Province. The main line is 26.98Km long and the connecting line is 8.1Km long. The pavement surface layer is 4cmAC13 modified asphalt concrete + 6cmAC20 Modified asphalt concrete + 8cmAC25 ordinary asphalt concrete. The main project quantities include: 189,000 m3 of graded gravel subbase, 265,000 m3 of water-stabilized base, and 119,000 m3 of asphalt concrete surface.

[0038] The construction unit increased investment and innovated construction technology to ensure the quality of pavement preparation. In the mixing plant and crushed stone processing plant, the silo site is hardened with 18cm thick water-stabilizing base materials. The roads in the site area are hardened with 20cm thick C20 concrete, and drainage facilities such as cross slopes and grouted rubble drainage ditches are set up to ensure that The drainage is smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com