Method for utilizing solid waste ardealite to prepare gypsum whiskers

A solid waste and gypsum whisker technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as difficult industrial application, complicated regulation, and complicated production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

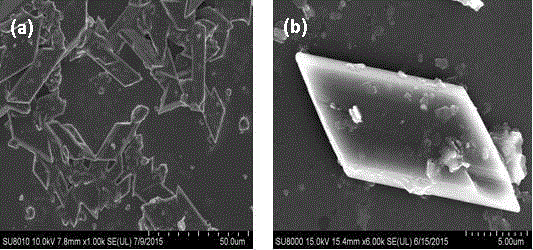

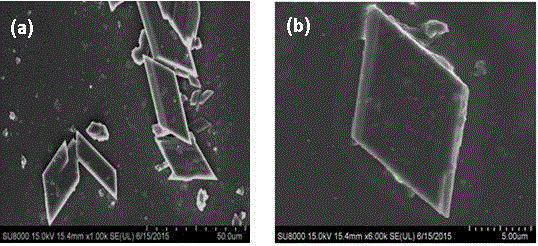

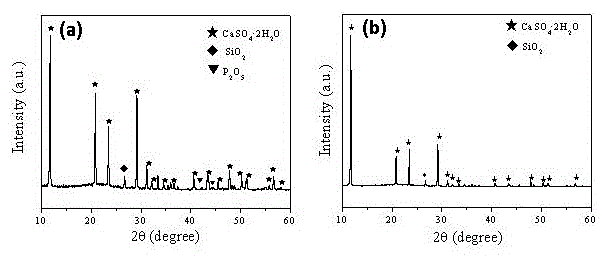

[0054]Specific embodiment 1: A method for preparing gypsum whiskers from solid waste phosphogypsum, including three processes of washing and pretreatment of phosphogypsum, centrifugal dehydration, and lime neutralization. Phosphogypsum with a low pH value is mixed with water in the reaction kettle, and then the floating matter in the upper layer of the clarified liquid is filtered out with a filter screen, and the remaining slurry is slowly stirred under a magnetic stirrer to obtain a uniform slurry suspension, and the uniform slurry is suspended The liquid is transferred to a centrifuge for dehydration, the clear liquid is transferred to a water treatment tank, and vacuum-dried to obtain purified phosphogypsum. Shake an appropriate amount of washed and purified phosphogypsum with a certain proportion of glycerol and water mixture, place it in a tube-type high-temperature furnace, and calcinate it at a temperature of 200-600°C for 1-3 hours, carry out crystallization reaction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com