IGCC (Integrated Gasification Combined Cycle) based pre-combustion CO2 capture system

A technology of CO2-H2 absorption tower, applied in inorganic chemistry, through absorption, separation of dispersed particles, etc., can solve the problems of low cost and high cost of oxygen enrichment, and achieve the effects of reducing emissions, increasing capture rate, and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

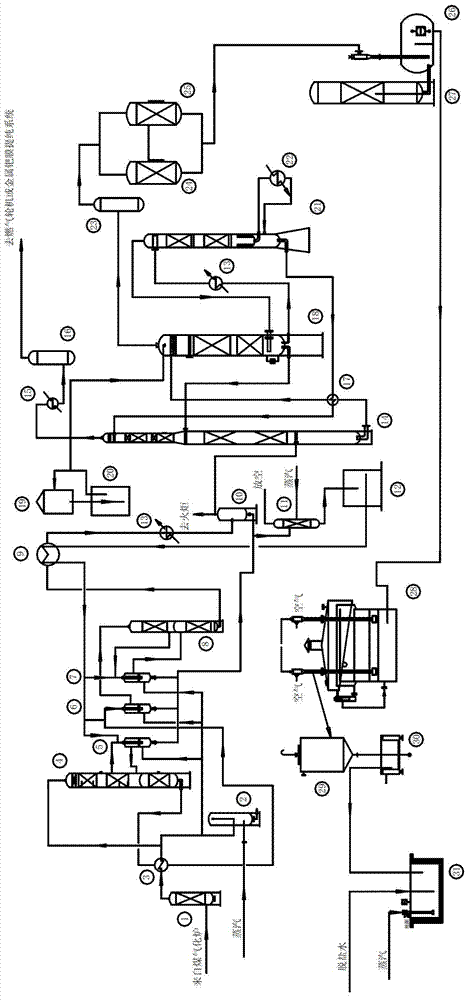

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0022] As shown in the drawings, the device of the present invention includes: a filter 1, a first water separator 2, a first heat exchanger 3, a shift furnace 4, a first humidifier 5, a second humidifier 6, a third humidifier Humidifier 7, Feedwater Preheater 9, Second Water Separator 10, Stripping Tower 11, Feedwater Tank 12, Third Heat Exchanger 13, Absorption Tower 14, Second Heat Exchanger 15, First Liquid Separator 16. Lean-rich liquid heat exchanger 17, desorption tower 18, first solution storage tank 19, second solution storage tank 20, regeneration tower 21, reboiler 22, second liquid separator 23, desulfurization purifier 24, 25 , H 2 S primary absorber 26, H 2 S secondary absorber 27, regeneration tank 28, sulfur foam tank 29, sulfur filter 30, liquid holding tank 31.

[0023] The filter 1 is connected to the coal gas synthesis g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com