Method and device for removing CO2 from conversion gas of synthetic ammonia

A technology for changing gas and synthesizing ammonia, which is applied in the field of CO2 removal, can solve the problems that have not been reported, and achieve the effects of increasing gas treatment capacity, reducing circulation volume, and increasing effective interface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

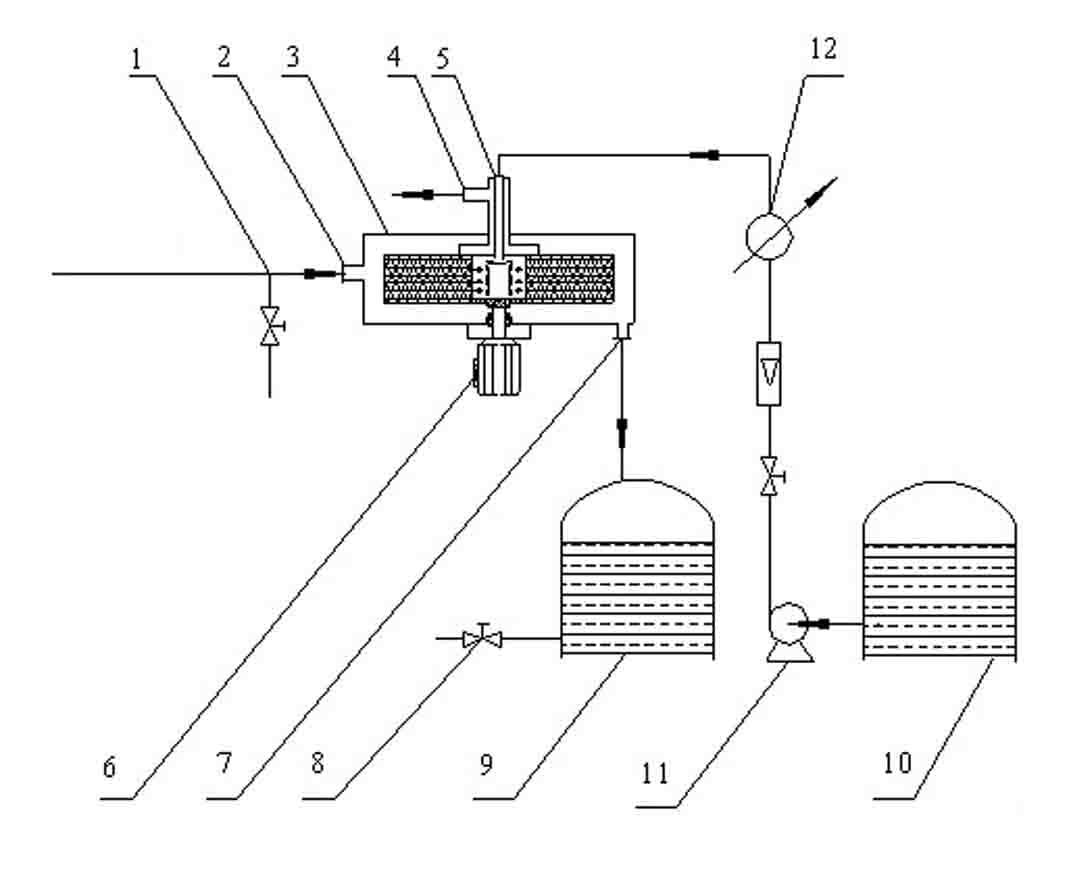

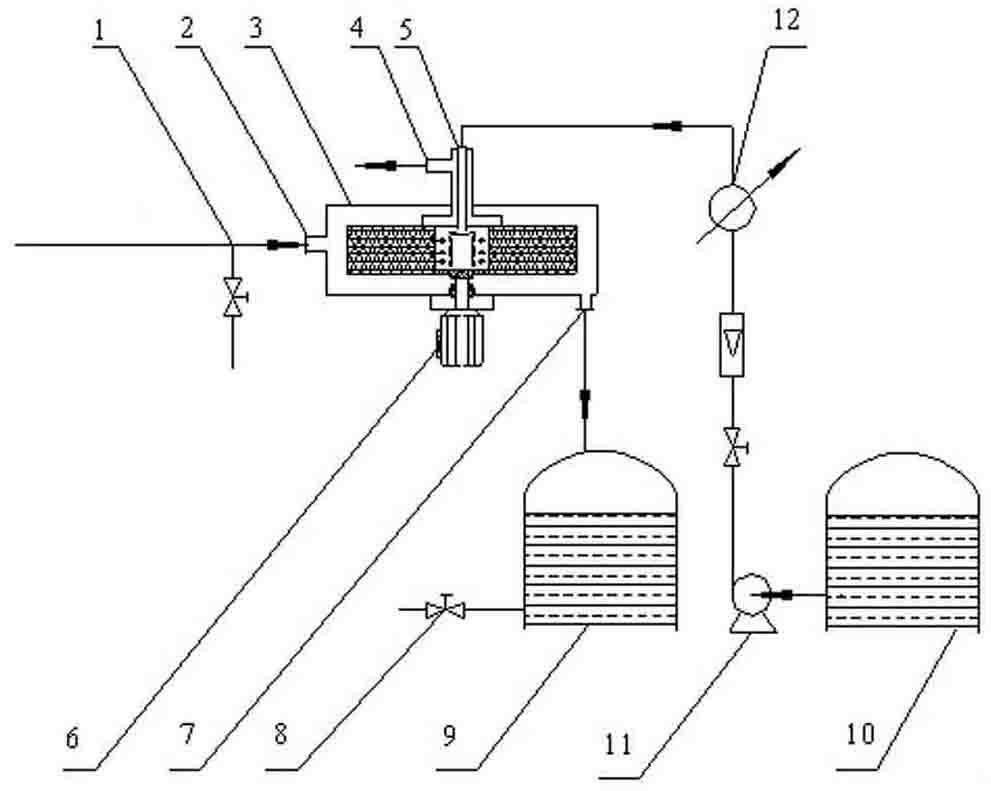

Image

Examples

Embodiment 1

[0043] Synthetic ammonia shift gas composition: hydrogen: 52.20%; carbon dioxide: 28.40%; nitrogen: 18.58%; carbon monoxide: 0.26%, the rest is a small amount of inert gas.

[0044] Absorbent composition: fresh NHD solvent.

[0045] Turn on the lean solution pump 10 to send the fresh NHD solvent to the ammonia cooler 12 to cool down to -5°C. Turn on the motor 6, adjust the rotor speed to 1200 r / min, adjust the flow meter to control the flow of the NHD solvent, send the cooled NHD solvent to the overweight machine 3, and cool it down to -5°C. Adjust the gas pressure at 2.7 MPa, it will contain 28.4% CO 2 The synthetic ammonia conversion gas enters the super-heavy machine through the gas inlet 2 of the super-heavy machine, and the adjusted gas volume is 60 m 3 h -1 , adjust the flow meter to control the flow of NHD solvent to 3m 3 h -1 , into the super-heavy machine through the liquid inlet 5, the NHD solvent is evenly sprayed on the inside of the packing layer through the ...

Embodiment 2

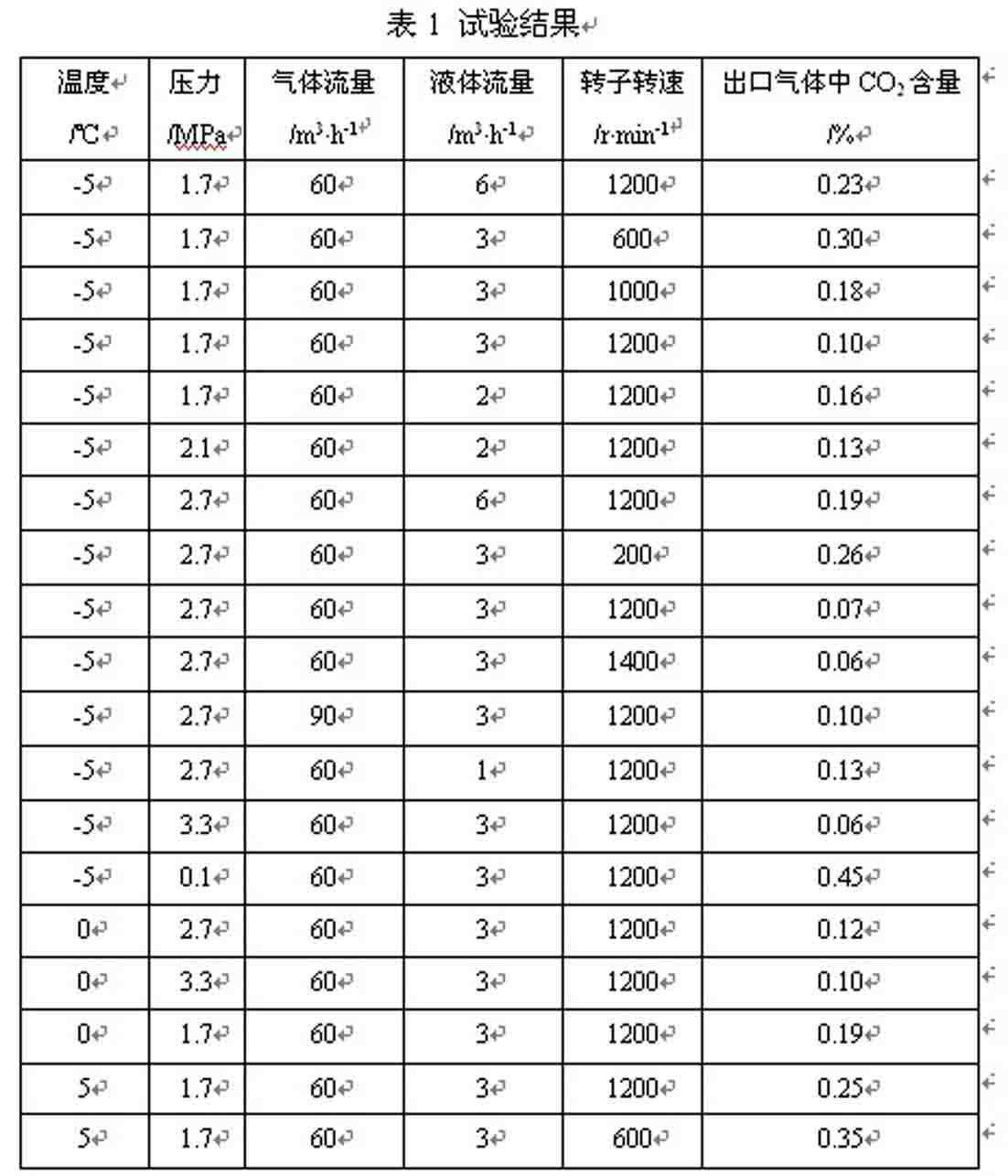

[0047] The process flow is the same as Example 1, and Example 2 investigates the content of carbon dioxide in the outlet gas of the overweight machine under different conditions such as temperature, pressure, gas flow rate, liquid flow rate, and rotor speed. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com