Method for catching carbon dioxide in flue gas by active sodium carbonate and apparatus thereof

A carbon dioxide and sodium carbonate technology, applied in chemical instruments and methods, carbon compounds, separation methods, etc., can solve the problem of high energy consumption for regeneration, and achieve the effects of low energy consumption for regeneration, cost reduction, and comprehensive treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

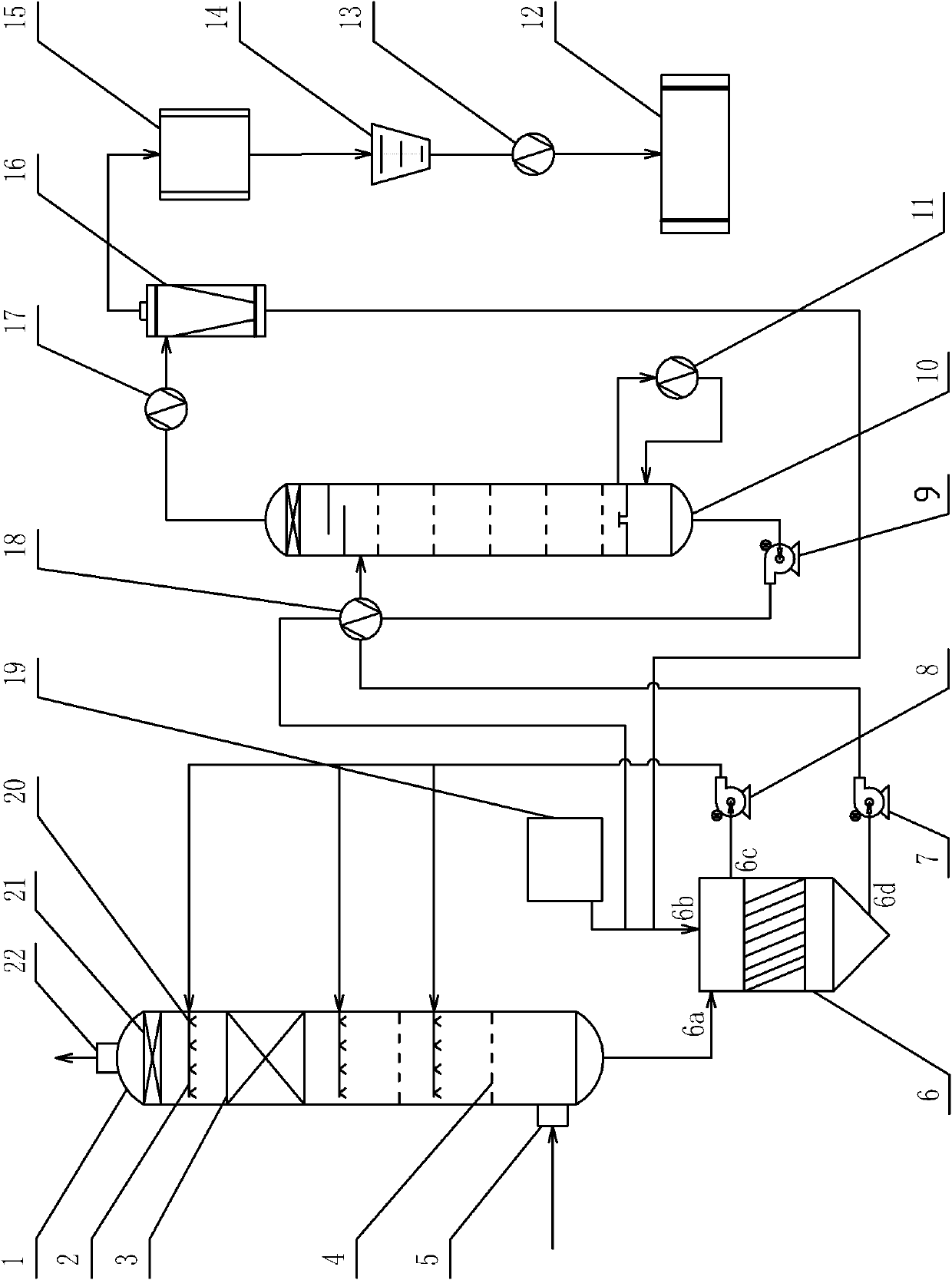

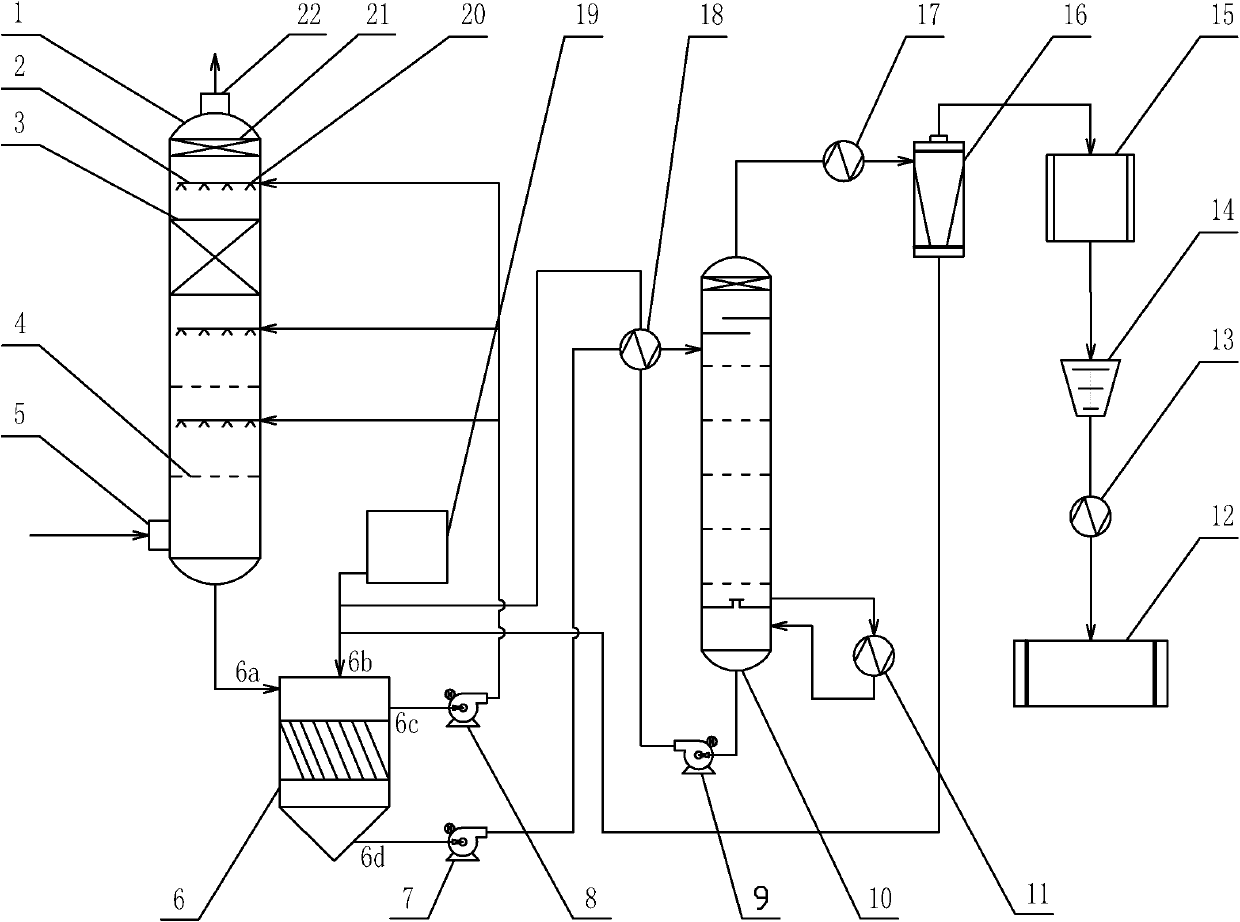

[0038] Below in conjunction with accompanying drawing and specific embodiment equipment of the present invention and technological process are described in further detail:

[0039] The equipment for capturing carbon dioxide in the flue gas of a power station by activated sodium carbonate shown in the figure is mainly composed of an absorption tower 1, a regeneration tower 10, a cooler 17, a gas-liquid separator 16, a dryer 15, a compressor 14 and Condenser 13 etc. are formed. Between the lower flue gas inlet 5 and the top flue gas outlet 22 of the absorption tower 1, three sets of absorbent spray layers 20 and one set of demisting devices 21 are sequentially arranged from bottom to top. Wherein the bottom of the uppermost group of absorbent spray layers 20 is provided with a layer of packing layer 3, and the bottoms of the other two groups of absorbent spray layers 20 are respectively provided with a flow equalizing sieve plate 4, and the hole area of the flow equalizing sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com