Method and device for selectively removing hydrogen sulfide by use of ultrasonically atomized liquid droplets

A hydrogen sulfide removal and ultrasonic atomization technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of methyldiethanolamine waste, low absorption efficiency, and weak desulfurization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In a 50000m 3 / h of natural gas production and treatment process, according to the method of the present invention, a droplet enhanced desulfurization and decarbonization device is used to enhance the separation of natural gas mixtures containing hydrogen sulfide and carbon dioxide to achieve high efficiency and low loss. The effective separation of natural gas and acid gas in a variety of acid gas mixtures, the specific operation process and effect are described as follows:

[0067] 1. Mixed gas properties and operating conditions

[0068] The mixed gas is natural gas, the main components are 96% alkanes, 1% hydrogen sulfide and about 9% carbon dioxide. Natural gas processing capacity is 5000m 3 / h, the operating temperature of the gas phase density is 50°C, and the operating pressure is 2.7MPa. The concentration of N-methylglycolamine solution (methyldiethanolamine) is 20-40%. It is atomized by an ultrasonic atomizer, and the average atomized particle diameter is below 50...

Embodiment approach

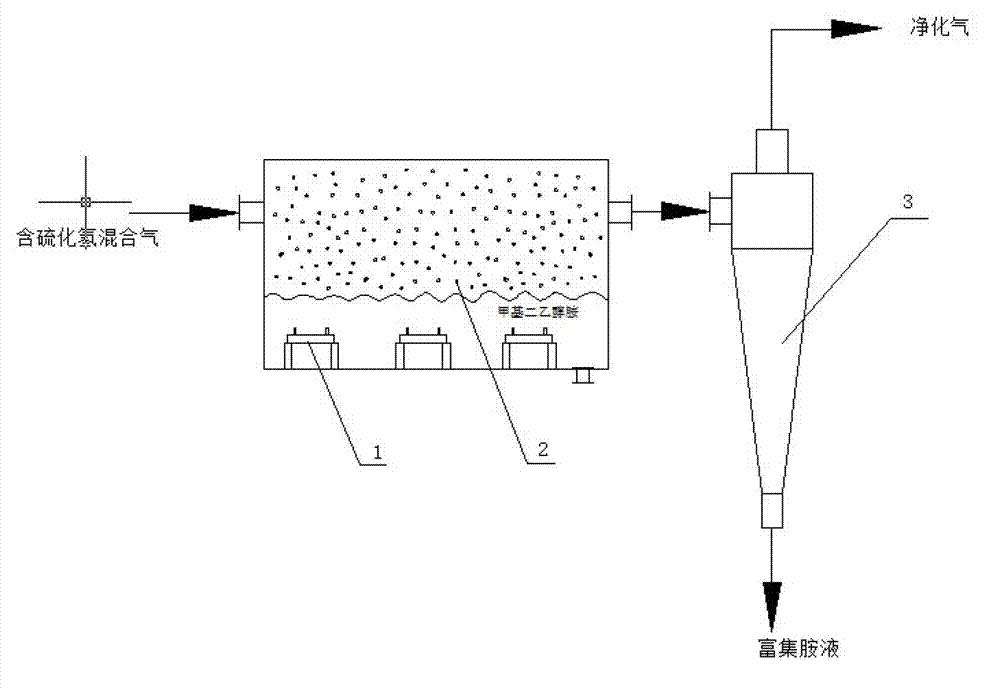

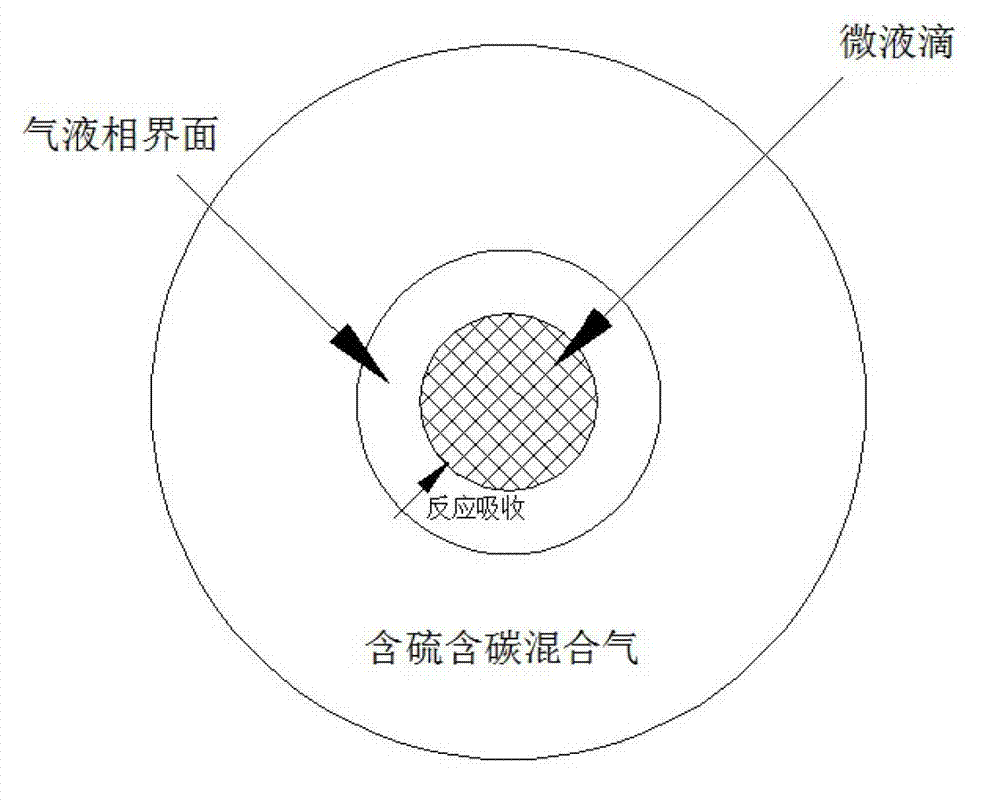

[0070] Methyldiethanolamine droplets are produced by an ultrasonic atomizer, the average droplet particle diameter is below 50 microns; the mixed gas containing sulfur and carbon quickly enters the cyclone; in the cyclone, a large number of methyldiethanolamine droplets It fully contacts and reacts with the sulfur and carbon components in the mixed gas; then, the desulfurized and decarbonized gas entrains methyldiethanolamine droplets into the cyclone, and performs ultra-low pressure drop gas-liquid cyclone separation; Diethanolamine is separated from the purified mixed gas, and the pressure drop is less than 30mmH 2 O (300Pa); the content of hydrogen sulfide in the purified gas is less than 10ppm; the methyldiethanolamine droplets are enriched, recovered, regenerated, and recycled.

[0071] 3. Experimental results

[0072] After separation by the use of droplet enhanced desulfurization and decarburization methods, the hydrogen sulfide content at the gas phase outlet of the cyclone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com