Organic amino supported metallic organic framework-porous polymer composite material as well as preparation method and application thereof

A metal-organic framework, porous polymer technology, applied in separation methods, chemical instruments and methods, educts, etc., to achieve the effects of high specific surface area, easy molding, and fast desorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Accurately weigh methyl acrylate (2.5g), ethylene glycol diacrylate (2.5g), Span20 (0.5g), toluene (1.0g) and oleic acid modified zinc oxide nanoparticles (1.5g) , into a 100mL three-necked round-bottomed flask under nitrogen protection. Then stir the oil phase with 600rpm, after stirring for 30min, add dropwise the water phase composed of 35.4mL deionized water, initiator ammonium persulfate (0.05g) and sodium chloride (0.71g), and continue stirring for 30min to produce a uniform and stable high The internal phase emulsion was then transferred to a centrifuge tube, sealed, and placed in an oven at 60° C. for 24 hours. The complete porous rod-shaped solid material was recovered from the tube, and then placed in a Soxhlet extraction device, extracted with a mixture of ethanol / water (1:1) for 24 h, and then extracted with ethanol for 24 h, and finally vacuumed at 80 °C After drying for 24 hours, a porous polymer material A containing metal nanoparticles was obtained....

Embodiment 2

[0057] (1) Accurately weigh methacrylic acid (2.5g), ethylene glycol dimethacrylate (2.5g), Span80 (0.5g), heptane (1.25g) and oleic acid modified iron oxide nanoparticles ( 1.75g), was added to a 100mL three-neck round bottom flask under nitrogen protection. Then the oil phase was stirred at 600rpm, and after stirring for 30min, a water phase consisting of 35.4mL of deionized water, initiator potassium persulfate (0.05g) and calcium sulfate (0.71g) was added dropwise, and stirring was continued for 30min to produce a uniform and stable high internal phase emulsion, then transferred to a centrifuge tube, sealed, and placed in an oven at 60°C for 24 hours. The complete porous rod-shaped solid material was recovered from the tube, and then placed in a Soxhlet extraction device, extracted with a mixture of ethanol / water (1:1) for 24 h, and then extracted with ethanol for 24 h, and finally vacuumed at 80 °C After drying for 24 hours, a porous polymer material D containing metal n...

Embodiment 3

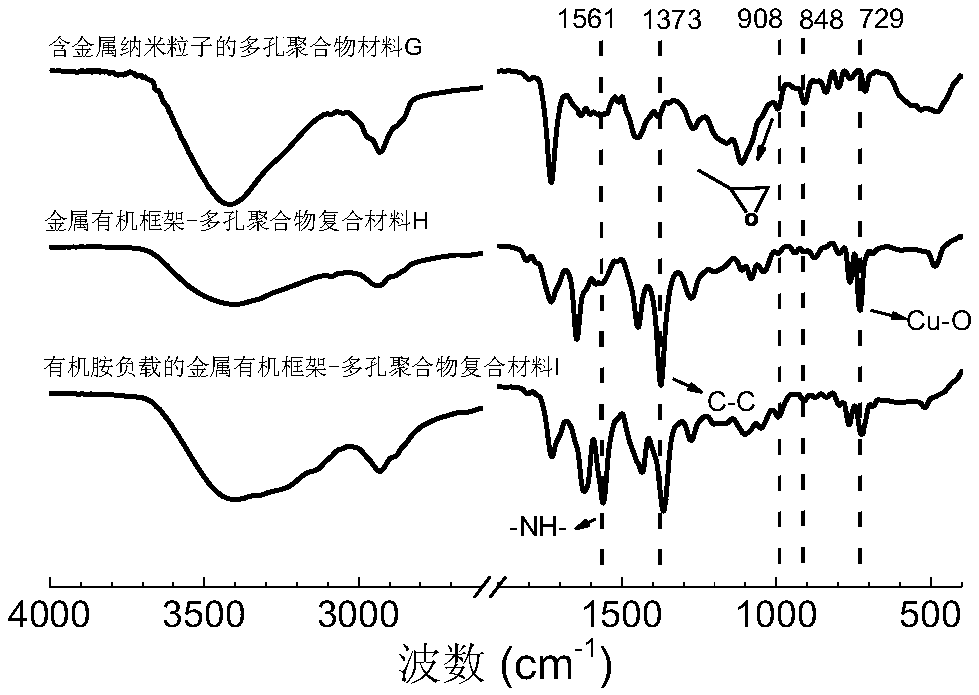

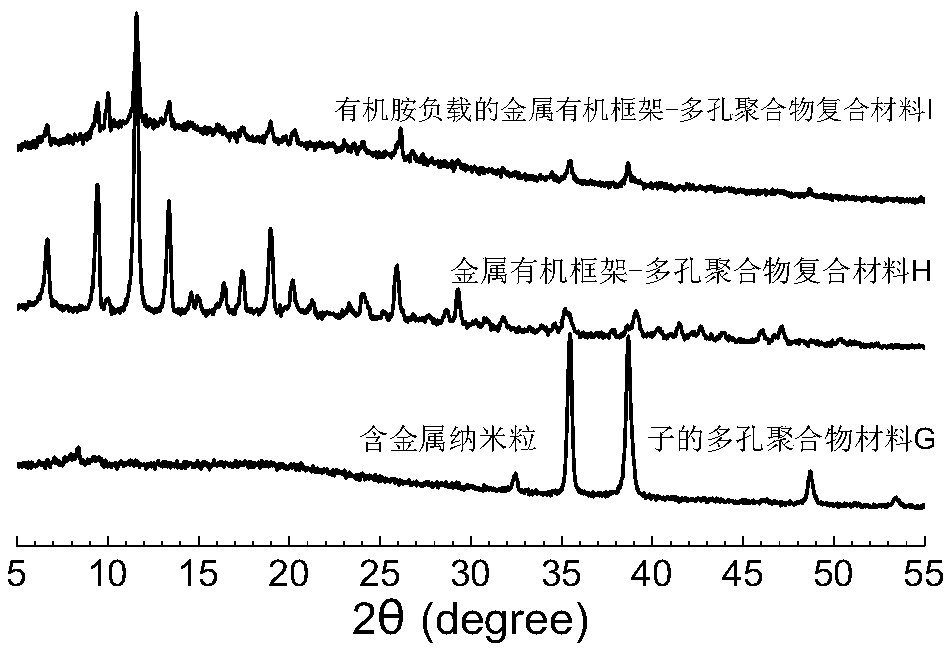

[0061] (1) Accurately weigh glycidyl methacrylate (2.5g), divinylbenzene (2.5g), poloxamer PEL121 (0.5g), dodecane (1.5g) and oleic acid modified oxidation Copper nanoparticles (2.0 g) were added into a 100 mL three-necked round bottom flask under nitrogen protection. Then the oil phase was stirred at 600rpm, and after stirring for 30min, a water phase composed of 35.4mL deionized water, initiator potassium persulfate (0.05g) and calcium chloride (0.71g) was added dropwise, and stirring was continued for 30min to produce a uniform and stable high The internal phase emulsion was then transferred to a centrifuge tube, sealed, and placed in an oven at 60° C. for 24 hours. The complete porous rod-shaped solid material was recovered from the tube, and then placed in a Soxhlet extraction device, extracted with a mixture of ethanol / water (1:1) for 24 h, and then extracted with ethanol for 24 h, and finally vacuumed at 80 °C After drying for 24 hours, a porous polymer material G cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com