High-selectivity compound desulfurizer and preparation method thereof

A high-selectivity, desulfurizing agent technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of limited absorption capacity, poor control of regeneration conditions, and high content of corrosion products to achieve enhanced desulfurization Effect, high economic and environmental benefits, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

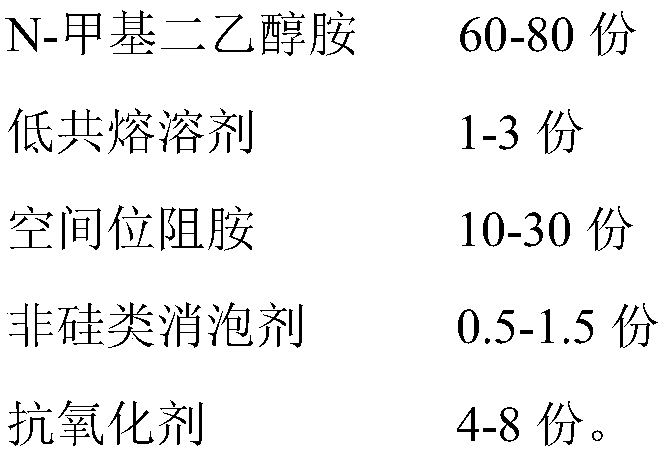

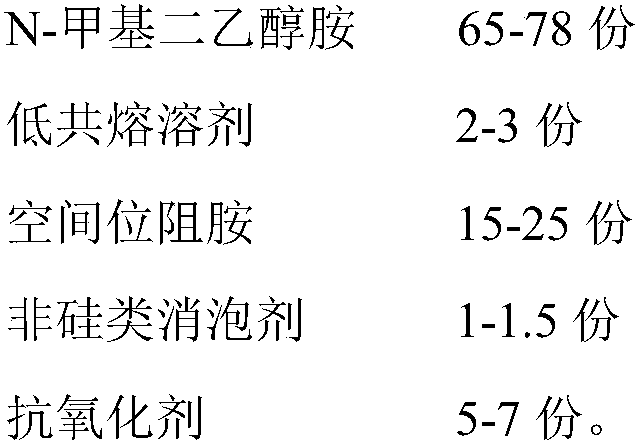

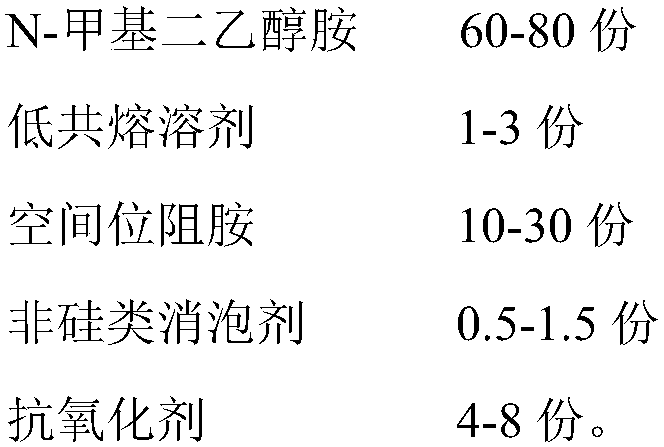

Method used

Image

Examples

Embodiment 1

[0032]Stir and mix 30 parts of N-methyldiethanolamine and 1 part of tetrabutylammonium chloride-polyethylene glycol to obtain compound desulfurizer A; then take 30 parts of N-methyldiethanolamine and 10 parts of piperazine Stir and mix evenly to obtain compound desulfurizer B; add compound desulfurizers A and B and 4 parts of 2,6-di-tert-butylphenol into the mixing kettle and stir for 15 minutes; then add polyethylene glycol under stirring 0.5 part of diol was stirred continuously for 15 minutes to prepare a compound desulfurizer.

Embodiment 2

[0034] Stir and mix 35 parts of N-methyldiethanolamine and 2.5 parts of tetrabutylammonium bromide-propionic acid to obtain compound desulfurizer A; then take 35 parts of N-methyldiethanolamine and 18 parts of 2-piperidine ethanol 6 parts of compound desulfurizers A and B and diethylhydroxylamine were added to the mixing kettle and stirred for 15 minutes; then 1.2 parts of tributyl phosphate were added under stirring Stirring was continued for 15 minutes to obtain a composite desulfurizer.

Embodiment 3

[0036] Add 70 parts of N-methyldiethanolamine, 2.5 parts of tetrabutylammonium bromide-caprolactam, 18 parts of tert-butylaminodiethanolamine, and 6 parts of p-hydroxybenzoic acid into the mixing tank, and stir for 20 minutes; then add phosphoric acid under stirring 1.2 parts of tributyl ester, continue to stir for 15 minutes to prepare a compound desulfurizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com