Composite organic alcohol amine absorbing agent for carbon dioxide

A carbon dioxide, organic alcohol amine technology, applied in chemical instruments and methods, dispersed particle separation, air quality improvement and other directions, can solve the problems of high solution loss, system equipment corrosion, large regeneration energy consumption, etc., to achieve high absorption efficiency, The effect of reducing energy consumption for regeneration and reducing loss of solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

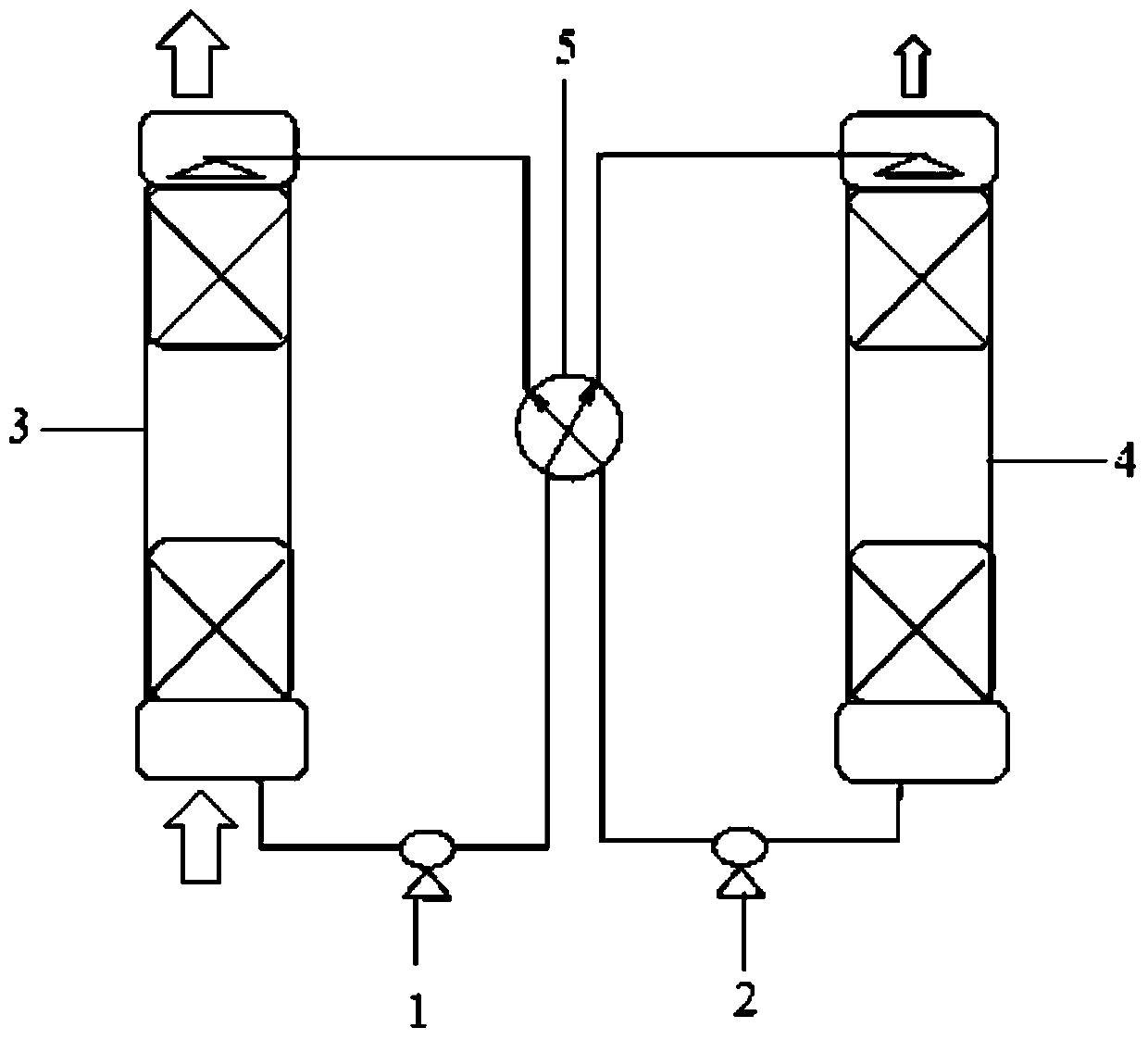

Image

Examples

Embodiment 1

[0026] A composite organic alkanolamine carbon dioxide absorbent, based on the overall mass of the absorbent as 100%, wherein the components and their mass percentages are as follows:

[0027] Main absorbent: monoethanolamine 50.97%, triethanolamine 49%, antioxidant: sodium sulfite 0.01%, corrosion inhibitor: sodium vanadate 0.01% and complexing agent: edetate disodium salt 0.01%.

Embodiment 2

[0029] A composite organic alkanolamine carbon dioxide absorbent, based on the overall mass of the absorbent as 100%, wherein the components and their mass percentages are as follows:

[0030] Main absorbent: monoethanolamine 67%, diethanolamine 30%, antioxidant: sodium sulfite 1%, corrosion inhibitor: sodium molybdate 1%, absorption enhancer: glycerol 0.5%, complexing agent: ethylenediaminetetraacetic acid Disodium salt 0.3%, defoamer: simethicone 0.1% and surfactant: sodium dodecylbenzenesulfonate 0.1%.

Embodiment 3

[0032] A composite organic alkanolamine carbon dioxide absorbent, based on the overall mass of the absorbent as 100%, wherein the components and their mass percentages are as follows:

[0033] Main absorbent: N-methyldiethanolamine 80%, auxiliary absorbent: piperazine 17.2%, antioxidant: potassium sulfite 1%, corrosion inhibitor: sodium vanadate 1%, absorption enhancer: potassium hydroxide 0.5% , glycerol 0.1%, complexing agent: tetrasodium edetate 0.1% and defoamer: XIAMETER AFE-14100.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com