Absorbent which gathers carbon dioxide in flue gas or synthesis gas

A carbon dioxide and absorbent technology, which is applied in reagents, chemical instruments and methods, and separation of dispersed particles, can solve the problems of strong corrosion of equipment, easy degradation of absorbents, and high regeneration energy consumption, so as to reduce operating costs and reduce solvent loss , The effect of low regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 20g of 2-(methylamino)ethanol (NMEA), 8.33g of N-methyldiethanolamine (MDEA), 1.67g of piperazine (PZ), and 70g of water to make a 30% mixed absorbent, of which 2-(methyl Amino) ethanol accounts for 20wt%, N-methyldiethanolamine accounts for 8.33%, piperazine accounts for 1.67%, and water accounts for 70wt%.

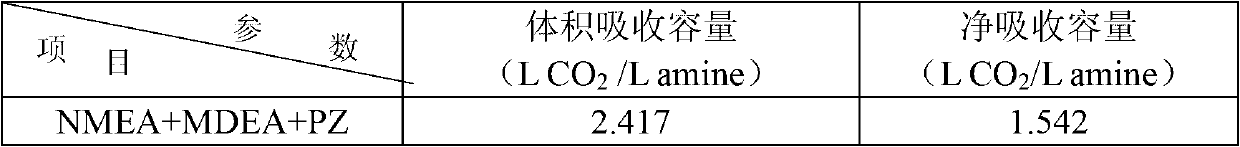

[0027] The mixed gas flow rate is 2L / min, and the composition is 15vt%CO 2 and 85vt%N 2 . The mixed gas is passed into the above mixed absorbent at normal pressure and 40°C for absorption. After the gas-liquid two phases reach equilibrium, the absorbed liquid is placed at 120°C and the back pressure is 0.1MPa for regeneration. Its volume absorption capacity and net absorption capacity are shown in Table 3:

[0028] Table 1 2-(methylamino)ethanol 20wt% + N-methyldiethanolamine 8.33wt% + piperazine 1.67wt%

[0029]

Embodiment 2

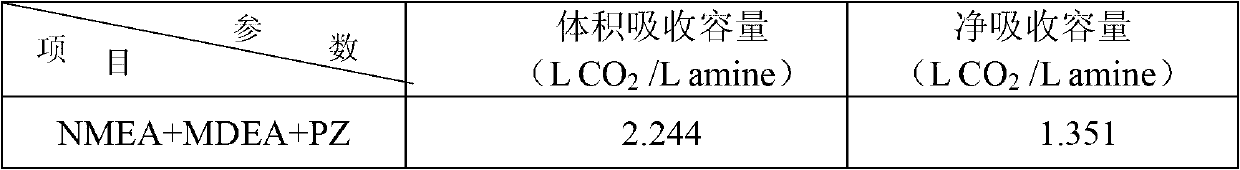

[0031] Take 15g of 2-(methylamino)ethanol (NMEA), 12.5g of N-methyldiethanolamine (MDEA), 2.5g of piperazine (PZ), and 70g of water to make a 30% mixed absorbent, of which 2-(methyl Amino) ethanol accounts for 15wt%, N-methyldiethanolamine accounts for 12.5%, piperazine accounts for 2.5%, and water accounts for 70%.

[0032] The mixed gas flow rate is 2L / min, and the composition is 15vt%CO 2 and 85vt%N 2 . The mixed gas is passed into the above mixed absorbent at normal pressure and 40°C for absorption. After the gas-liquid two phases reach equilibrium, the absorbed liquid is placed at 120°C and the back pressure is 0.1MPa for regeneration. Its volume absorption capacity and net absorption capacity are shown in Table 1:

[0033] Table 2 2-(methylamino)ethanol 15wt% + N-methyldiethanolamine 12.5wt% + piperazine 2.5wt%

[0034]

Embodiment 3

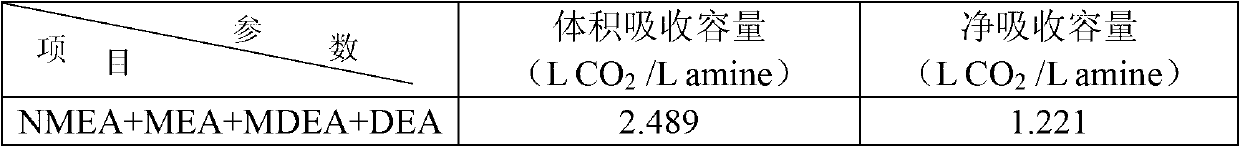

[0036] Take 15g of monoethanolamine (MEA), 5g of 2-(methylamino)ethanol (NMEA), 5g of N-methyldiethanolamine (MDEA), 5g of diethanolamine (DEA), and 70g of water to prepare a 30% mixed absorbent, of which Monoethanolamine accounts for 15 wt%, 2-(methylamino)ethanol accounts for 5 wt%, N-methyldiethanolamine accounts for 5 wt%, diethanolamine accounts for 5 wt%, and water accounts for 70 wt%.

[0037] The mixed gas flow rate is 2L / min, and the composition is 15vt%CO 2 and 85vt%N 2 . The mixed gas is passed into the above mixed absorbent at normal pressure and 40°C for absorption. After the gas-liquid two phases reach equilibrium, the absorbed liquid is placed at 120°C and the back pressure is 0.1MPa for regeneration. Its volume absorption capacity and net absorption capacity are shown in Table 3:

[0038]Table 3 30% monoethanolamine 15wt% + 2-(methylamino) ethanol 5wt% + N-methyldiethanolamine 5wt% + diethanolamine 5wt%

[0039]

[0040] From Example 1 and Example 2, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com