Preparation method of attapulgite based CO2 adsorption material with polyacrylamide grafted surface

A technology of polyacrylamide and surface grafting, which is applied in the field of preparation of CO2 adsorption materials, can solve the problems of poor adsorption selectivity, and achieve the effects of low regeneration energy consumption, good adsorption capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

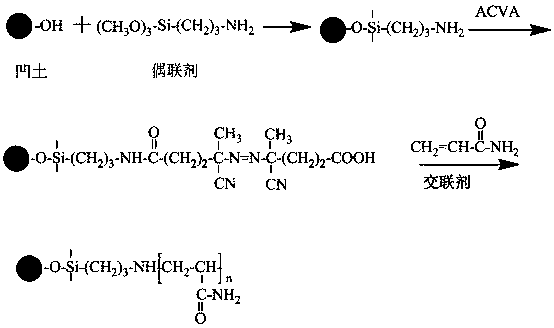

[0030] Embodiment 1: Prepare composite adsorbent according to the following steps

[0031] (1) Dry the attapulgite clay at 105°C and crush it through 200 mesh; add 3g of dried attapulgite clay and 100ml of organic solvent toluene into the container, add 3ml of silane coupling agent γ-aminopropyltri Ethoxysilane, placed in ultrasonic at 40°C for 50 minutes; reacted in a constant temperature oil bath with magnetic stirring at 40°C for another 5 hours; the reaction product was filtered and washed with toluene, absolute ethanol and deionized water in sequence, and dried at 105°C , crushing and grinding to obtain modified attapulgite clay;

[0032] (2) Mix 40ml of dichloromethane and 0.4ml of triethylamine into a round bottom flask, then add 0.75g of initiator ACVA and 1g of modified attapulgite clay into the round bottom flask, stir the above mixture at room temperature for 6h and mix well , wash and filter the solid matter alternately with high-purity water and absolute ethanol,...

Embodiment 2

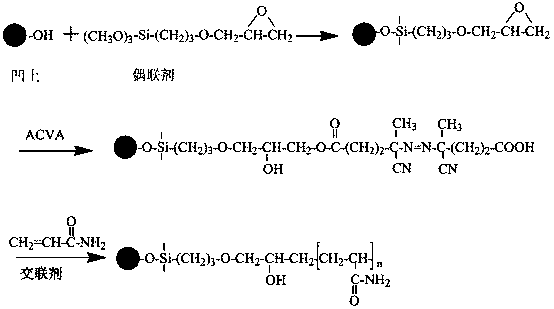

[0034] Embodiment 2: prepare composite adsorbent according to the following steps

[0035] (1) Dry the attapulgite clay at 105°C and crush it through 200 meshes; add 3g of dried attapulgite clay and 150ml of organic solvent absolute ethanol into the container, and add 4ml of silane coupling agent γ-glycidol during the stirring process Etheroxypropyl trimethoxysilane, placed in ultrasonic at 45°C for 40 minutes; reacted in a constant temperature oil bath with magnetic stirring at 50°C for 4 hours; the reaction product was filtered and washed with toluene, absolute ethanol and deionized water in sequence, Drying at 105°C, crushing and grinding to obtain modified attapulgite clay;

[0036] (2) Mix 50ml of dichloromethane and 0.5ml of triethylamine into a round-bottomed flask, then add 1g of initiator ACVA and 1.5g of modified attapulgite clay into the round-bottomed flask, and stir the above mixture at room temperature for 6h. Evenly, alternately wash and filter out solid matter...

Embodiment 3

[0038] Embodiment 3: prepare composite adsorbent according to the following steps

[0039] (1) Dry the attapulgite clay at 105°C and crush it through 200 meshes; add 3g of dried attapulgite clay and 150ml of organic solvent absolute ethanol into the container, and add 5ml of silane coupling agent γ-aminopropanol during stirring Triethoxysilane was placed in ultrasonic wave at 45°C for 30 minutes; reacted in a constant temperature oil bath with magnetic stirring at 60°C for 3 hours; the reaction product was filtered and washed with toluene, absolute ethanol and deionized water in sequence, Drying at 105°C, crushing and grinding to obtain modified attapulgite clay;

[0040] (2) Mix 60ml of dichloromethane and 0.6ml of triethylamine into a round bottom flask, then add 1.5g of initiator ACVA and 2g of modified attapulgite clay into the round bottom flask, and stir the above mixture at room temperature for 6h to mix Evenly, alternately wash and filter out solid matter with high-pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com